FuelSystem

Maintenance

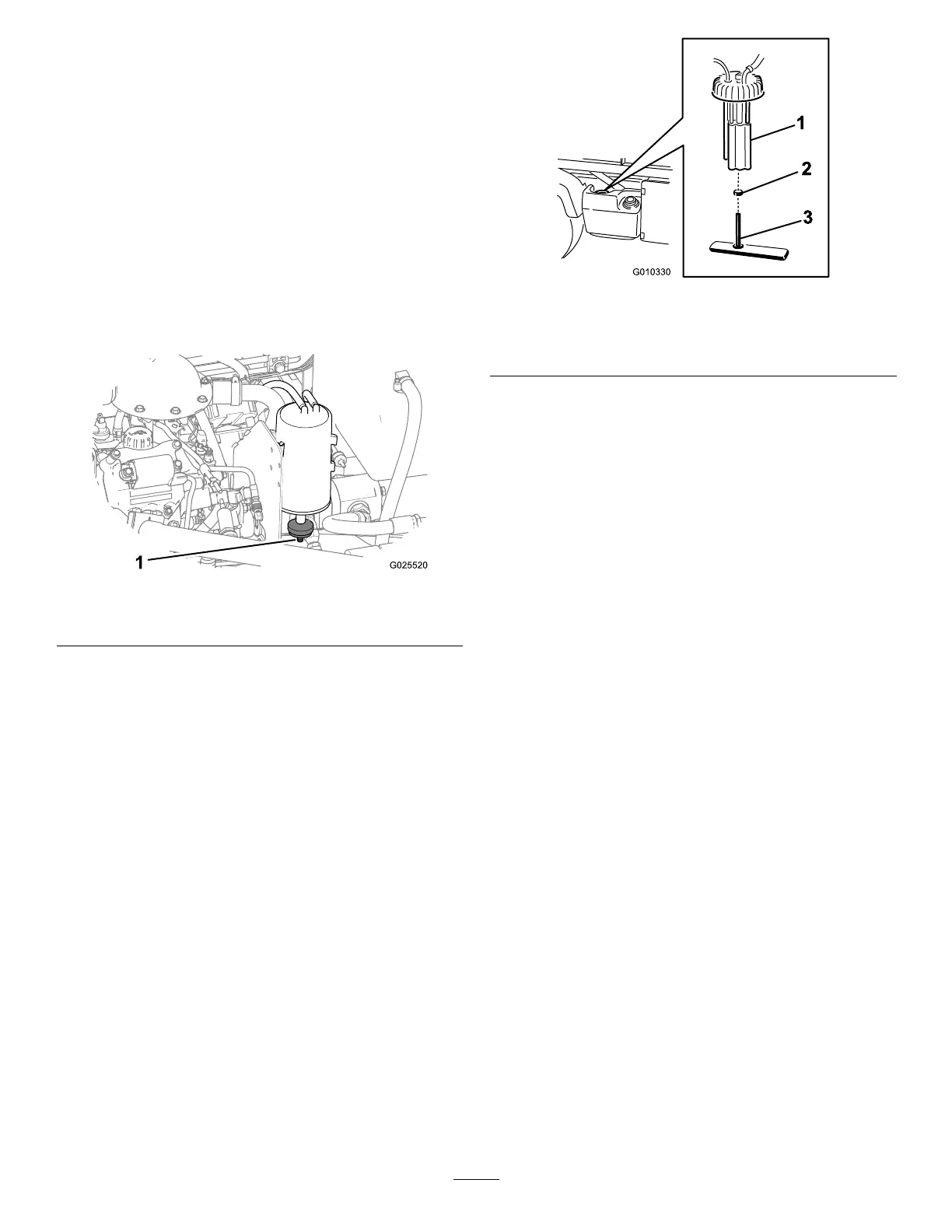

InspectingtheCarbon

CanisterAirFilter

ServiceInterval:Aftertherst50hours—Inspectthe

openingonthelter.

Every200hours—Changethecarboncanister

airlter.

1.Locatetheairlteronthebottomofthecarbon

canister(Figure47).

g025520

Figure47

1.Filteropening

2.Ensurethattheopeningonthebottomofthe

lterisclearandopen.

3.Removeandinstallthenewlter(ifnecessary).

ReplacingtheFuelFilter

ServiceInterval:Every400hours

1.Raisethebedandplacethesafetysupporton

theextended-liftcylindertoholdupthebed.

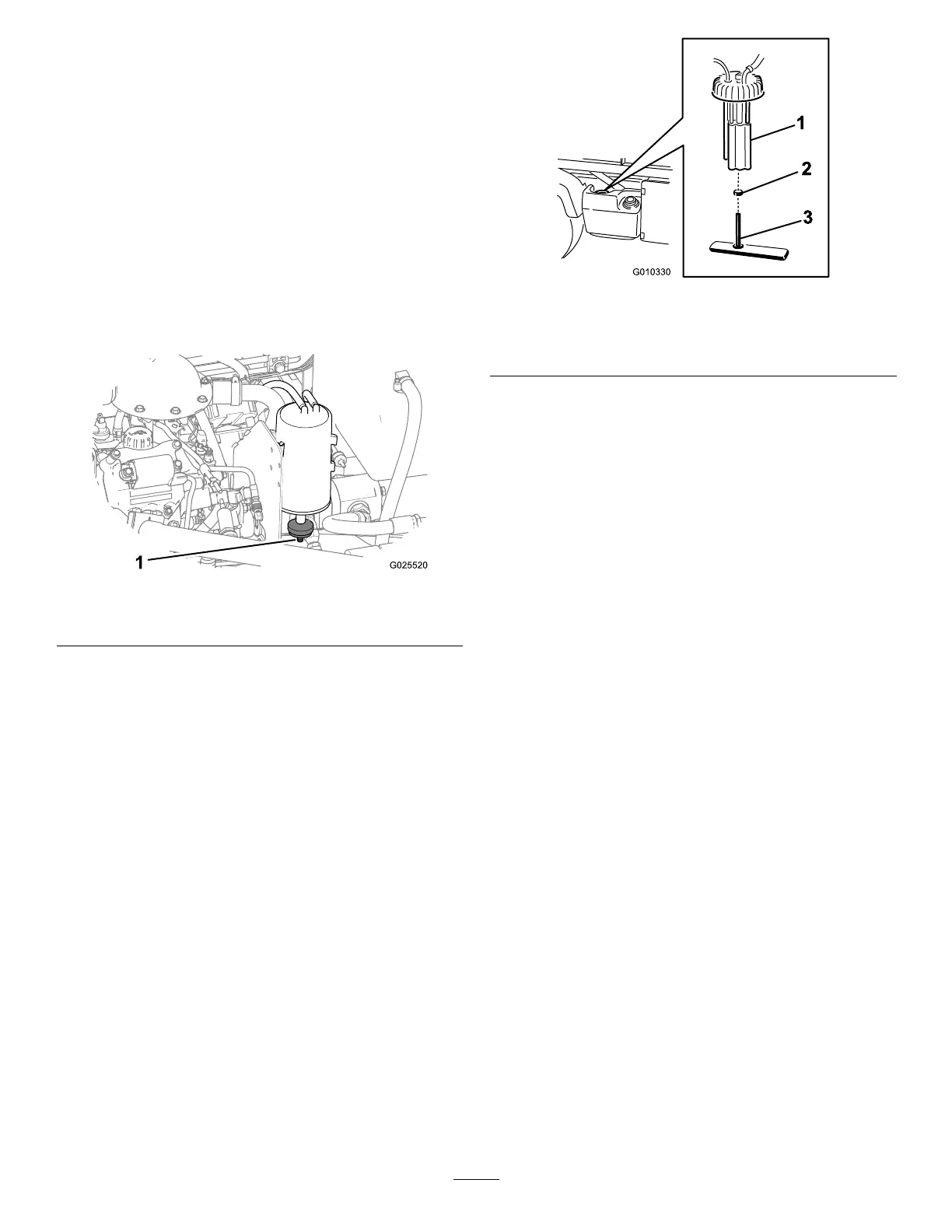

2.Unplugthewire-harnessconnectorsfromthe

fuelpump(Figure48).

3.Loosenthehoseclampanddisconnectthefuel

linefromthefuel-pumpcap(Figure48).

g010330

Figure48

1.Fuelpump

3.Fuelline/fuellter

2.Hoseclamp

4.Removethefuel-pumpcapfromthetopofthe

fueltank(Figure48).

Important:Donotallowthefuel-pump

assemblytorotateinthetankwhileremoving

thefuelpump.Damagetotheoatassembly

canoccurifthefuelpumprotatesinsidethe

fueltank.

5.Removethefuel-pumpassemblyandthefuel

lterfromthetank(Figure48).

6.Removetheclampsecuringthefuellterhose

tothefuel-pumptting.

7.Removethehosefromthetting(Figure48).

8.Insertthenewhoseclampontothenew

fuel-lterhose.

9.Insertthehoseontothefuelpumpandsecure

theclamp.

10.Inserttheassemblyintothefueltank,and

tightenthecapto20to22N∙m(175to200in-lb).

11.Connectthewiresandsecurethehosewiththe

hoseclamp.

InspectingFuelLinesand

Connections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Inspectthefuellines,ttings,andclampsforsignsof

leaking,deterioration,damage,orlooseconnections.

Note:Repairanydamagedorleakingfuelsystem

componentbeforeusingthemachine.

44

Loading...

Loading...