3.Removetheairlterfromthehousing(Figure

40).

Note:Donotcleanausedlterelement

becauseyoumaydamagetheltermedia.

4.Wipecleantheinterioroftheair-ltercoverand

housing(Figure40).

5.Removetherubberdustvalvefromthecover

(Figure40).

6.Cleanthedirt-ejectionportlocatedinthe

air-cleanercover,thedust-valvecavity,and

replacethedustvalve(Figure40).

7.Inspectthenewairlterforshippingdamage,

checkingthesealingendofthelterandthe

body.

Important:Donotuseadamagedelement.

8.Insertthenewairlterbyapplyinglightpressure

totheouterrimoftheltertoseatitinthe

air-lterhousing(Figure40).

9.Aligntheair-ltercoverwiththedustvalveatthe

6o’clockpositionwhenviewedfromtheleftend

ofthecover(Figure40).

10.Securethelatchoftheair-ltercover(Figure

40).

Note:Resettheindicatorifitshowsred(if

equipped).

ServicingtheEngineOil

Note:Changetheoilmorefrequentlywhenoperating

conditionsareextremelydustyorsandy.

Note:Disposeoftheusedengineoilandoillterata

certiedrecyclingcenter.

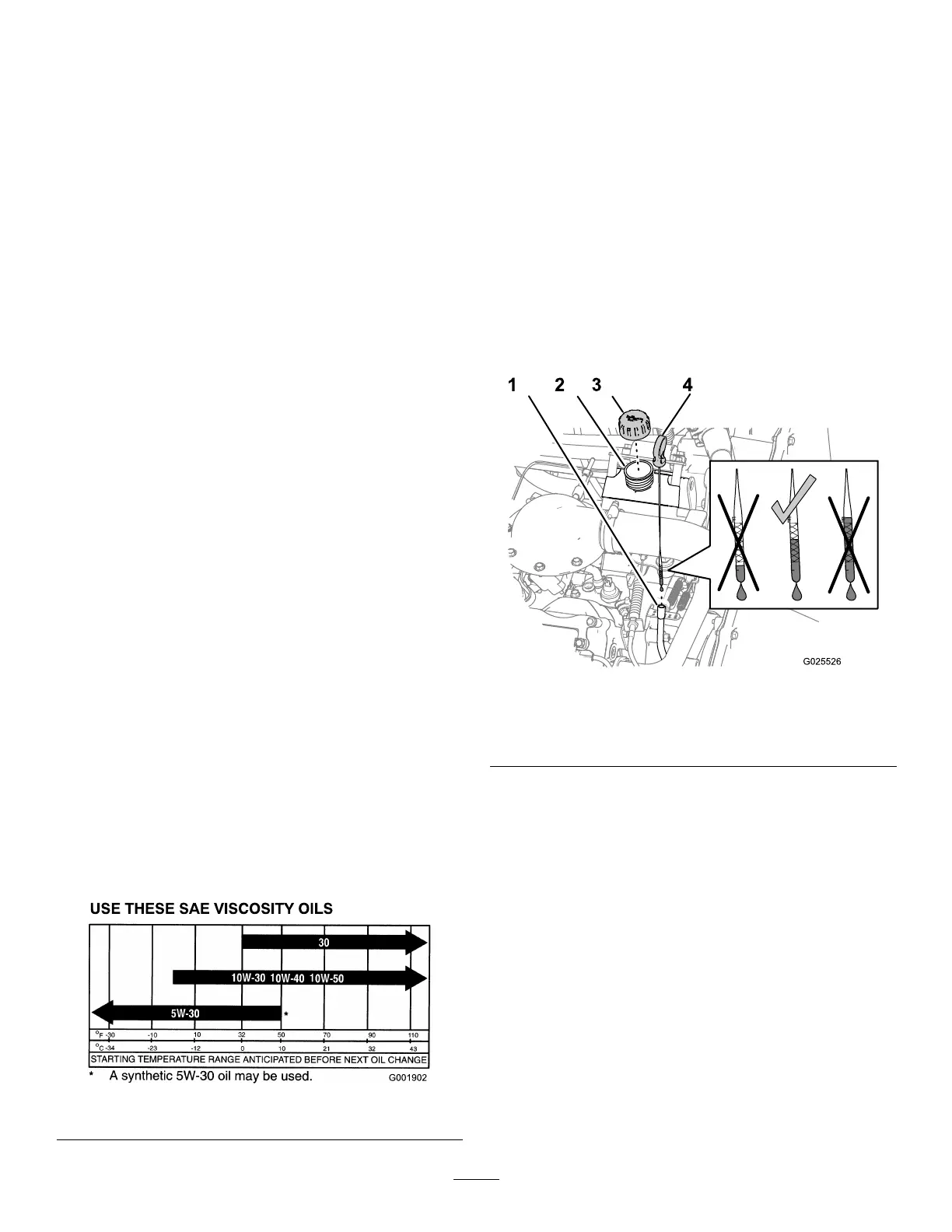

Engine-OilSpecications

OilType:Detergentengineoil(APISJorhigher)

CrankcaseCapacity:2.0L(2.1USqt)whenthe

lterischanged

Viscosity:Seethetablebelow.

g001902

Figure41

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevel.(Checktheoil

levelbeforeandaftertheengineis

rststartedanddailythereafter.)

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Iftheenginehasalreadyran,shutitoffandwait

foratleast10minutesbeforecheckingtheoillevel.

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Removethedipstickandwipeitwithacleanrag

(Figure42).

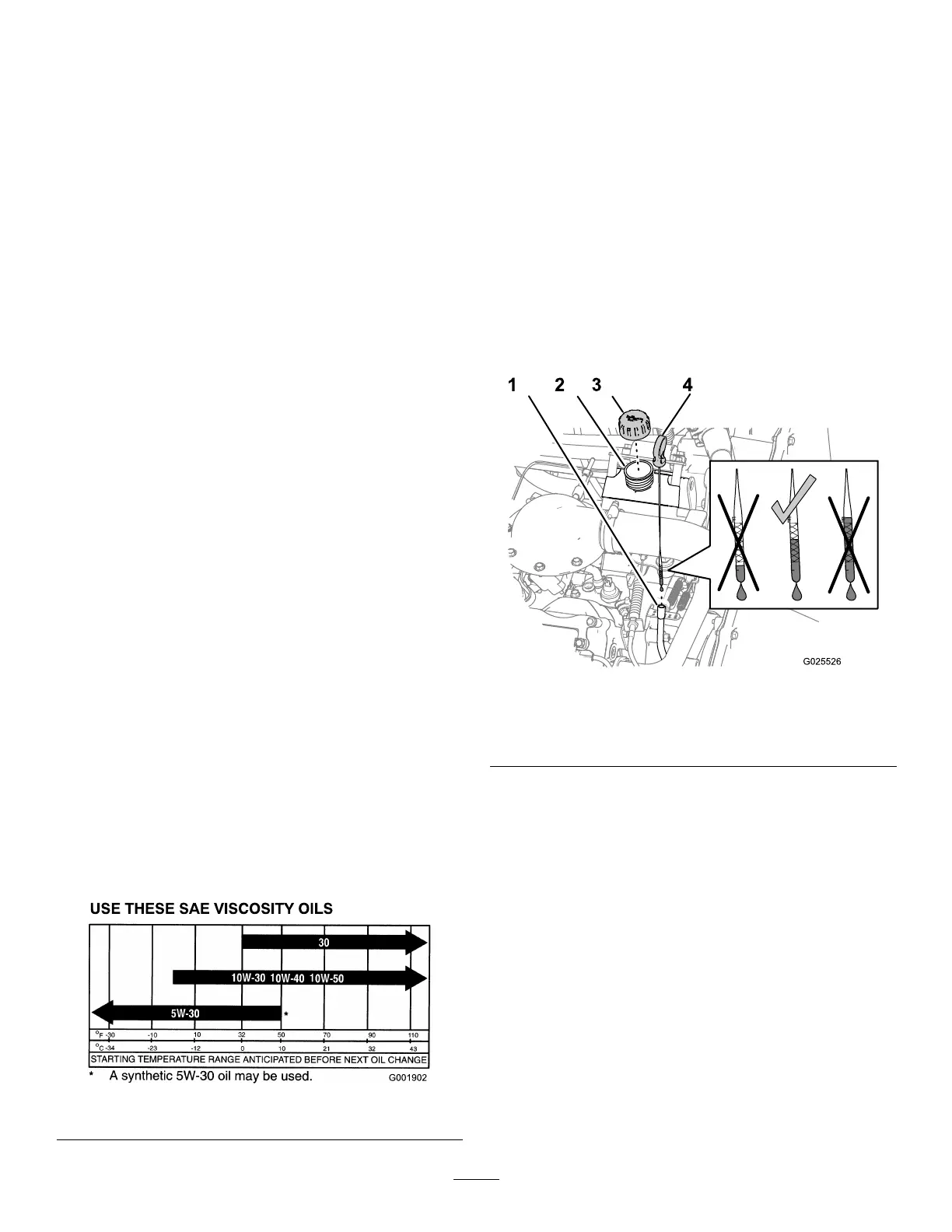

g025526

Figure42

1.Dipsticktube3.Fillercap

2.Fillerneck4.Dipstick

5.Insertthedipstickintothetubeandensurethat

itseatsfully.

6.Removedipstickandchecktheoillevel(Figure

42).

7.Iftheoillevelislow,removethellercap(Figure

42)andaddenoughoiltoraisetheleveltothe

Fullmarkonthedipstick.

Note:Whenaddingoil,removedipstickto

allowproperventing.Slowlypourtheoilintothe

llerneck,andchecktheleveloftenduringthis

process.Donotoverlltheenginewithoil.

41

Loading...

Loading...