modelwiththeHighFlowHydraulicKit(option)

orTCmodel.

6.Siphonthehydraulicuidfromthehydraulic

tank.

7.Removethesiphoningequipmentfromthe

hydraulictank(Figure82).

8.Add7.5L(2USgallons)—Non-TCmodelor

15.1L(4USgallons)—Non-TCmodelwiththe

HighFlowHydraulicKit(option)orTCmodelof

thespeciedhydraulicuidintothehydraulic

tank(Figure82).

Important:Useonlythehydraulicuids

specied.Otheruidscouldcausesystem

damage.

9.Installthedipstickandcaptothellerneckof

thehydraulictank(Figure82).

10.Starttheengineandoperatethemachinetoll

thehydraulicsystem.

11.Checkthehydraulic-uidlevelandreplenishit,

ifrequired.

RaisingtheCargoBedin

anEmergency

Thecargobedcanberaisedinanemergencywithout

startingtheenginebycrankingstarterorbyjumping

thehydraulicsystem.

RaisingtheCargoBedusingthe

Starter

Crankthestarterwhileholdingtheliftleverinthe

Raiseposition.Runthestarterfor10seconds,then

wait60secondsbeforeengagingthestarteragain.

Iftheenginedoesnotcrank,youmustremovethe

loadandbed(attachment)toservicetheengineor

transaxle.

RaisingtheCargoBedbyJumping

theHydraulicSystem

CAUTION

Araisedbedfullofmaterialwithouttheproper

safetysupportrodmaylowerunexpectedly.

Workingunderanunsupportedraisedbed

maycauseinjurytoyouorothers.

•Beforeservicingormakingadjustmentsto

themachine,parkthemachineonalevel

surface,engagetheparkingbrake,shutoff

theengine,andremovethekey.

•Removeanyloadmaterialfromthebed

orotherattachmentandinsertthesafety

supportonafullyextendedcylinderrod

beforeworkingunderaraisedbed.

Youwillneed2hydraulichoses,eachwithamale

andfemalequickcoupler,thattthemachine

couplers,toperformthisoperation.

1.Backanothermachineuptotherearofthe

disabledmachine.

Important:Themachinehydraulicsystem

usesDexronIIIATF .Toavoidsystem

contamination,makesurethatthemachine

usedtojumpthehydraulicsystemusesan

equivalentuid.

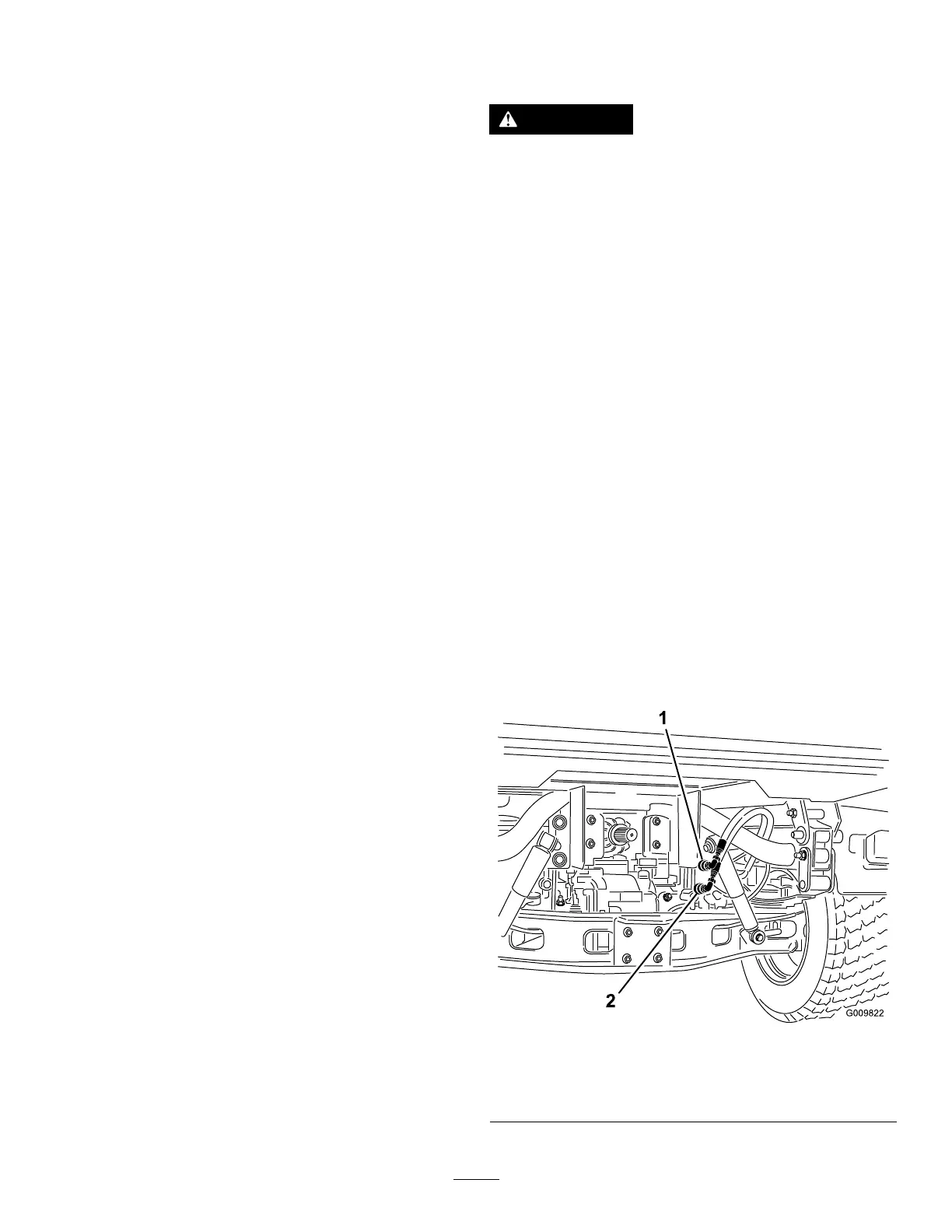

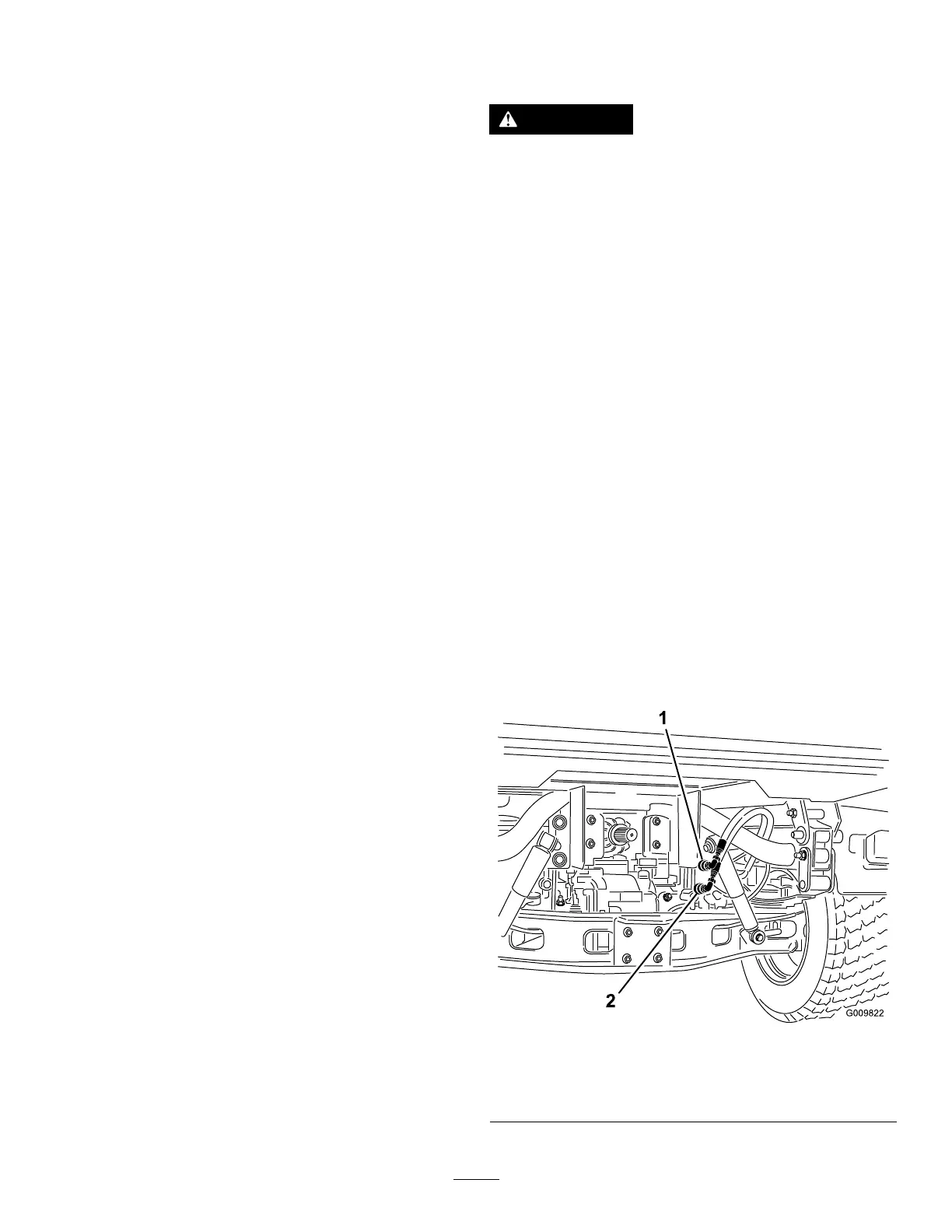

2.Onbothmachine,disconnectthe2quick-coupler

hosesfromthehosessecuredtothecoupler

bracket(Figure83).

g009822

Figure83

1.Quick-couplerhoseA

2.Quick-couplerhoseB

62

Loading...

Loading...