E6581595

F-33

6

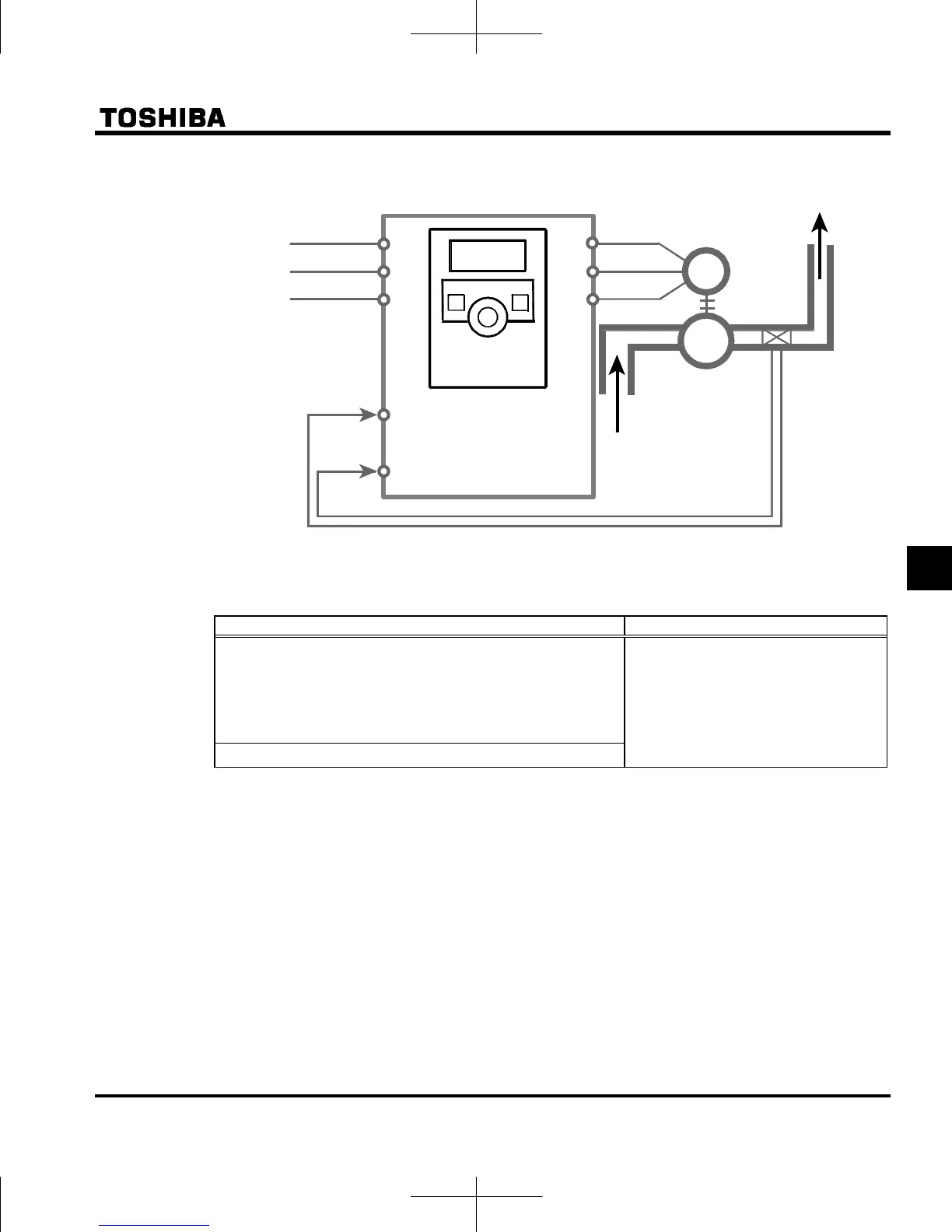

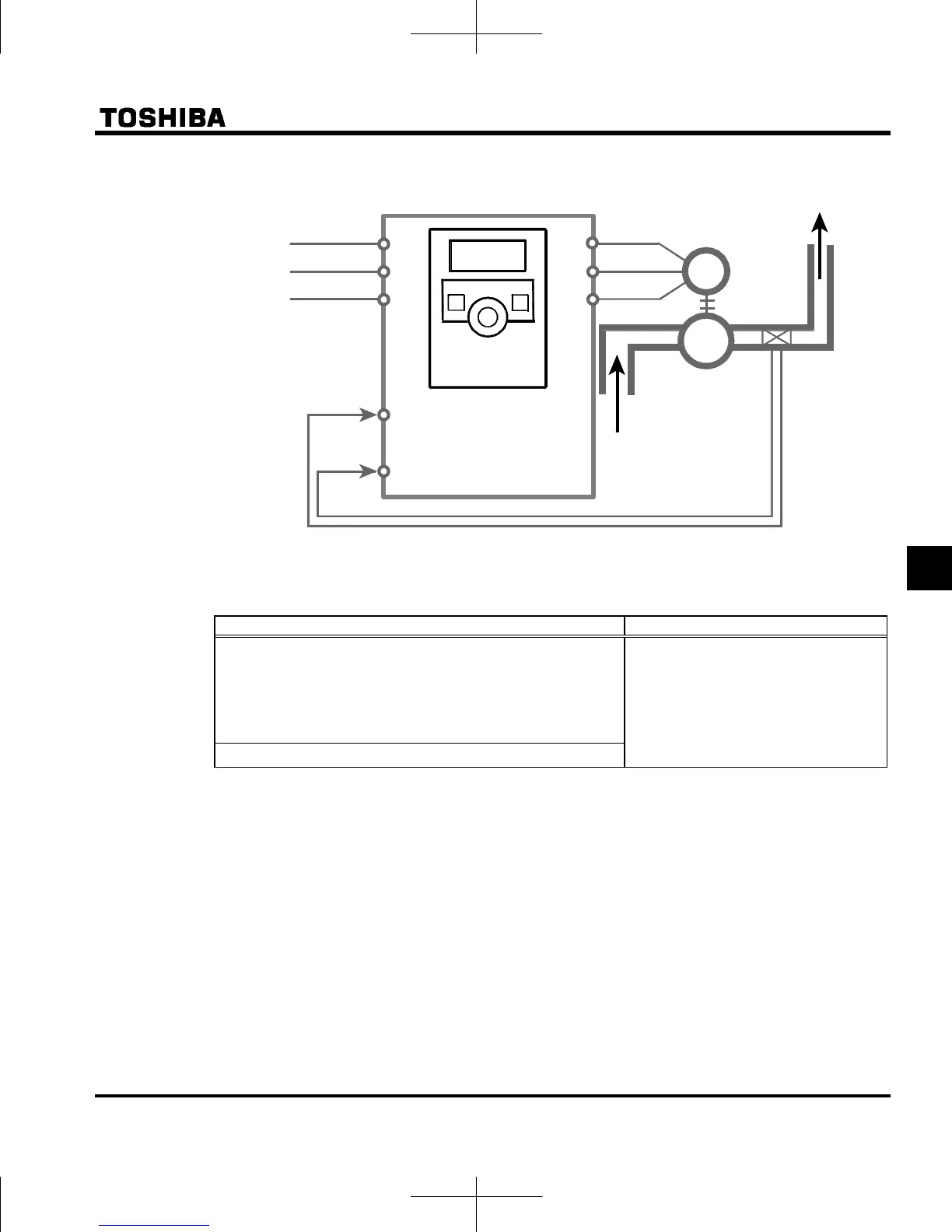

1) Example of External connection

2) Selecting PID set value and feedback value

PID set value (frequency) and feedback value can be combined as follows for the PID control.

①PID set value ②Feedback value

Frequency setup mode selection: Note 1

1: Setting dial 1 (press in center to save)

2: Setting dial 2 (save even if power is off)

3: RS485 communication

5: UP/DOWN from external logic input

Analog/logic input Selection

(VI terminal): f109 Note 2

0: Voltage signal input (0-10V)

1: Current signal input (4-20mA)

3: Voltage signal input (0-5V)

Preset-speed operation (, are all possible)

Note 1: Do not set (Terminal VI).

Note 2: Do not set (Logic input).

3) Setting PID control

Set : PID control=1(Enabled)

(1) Set : Acceleration time and : Deceleration time to the system fitting values.

(2) To limit the output frequency, set parameters : Upper limit frequency and : Lower limit frequency.

If PID set value are set with the setting dial, however, the process quantity setting range will be limited by

the settings of and .

Note 3: Assigning the terminal function number 36 (PID control prohibition) to an input terminal. PID control

function is stopped temporarily while the terminal is ON.

M

P

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

VI

CC

Pressure

transmitter

(1) Panel setting

(2) Internal preset-speed

setting

Feedback signals (1)DC : 4~20mA (2)DC : 0~10V (3)DC : 0~5V

(1) Panel keypad setting

Inverter

Motor

Pump

①PID set value setting

Setting dial

Pressure

transmitter

②Feedback value: Current signal input (4-20mA)

Loading...

Loading...