100

TK 61753-2-MM-EN

The ETV has two internal coils. The microprocessor operates the valve by energizing the coils with a variable frequency

AC signal. The valve position can be monitored with the Gauges Menu. Zero (0) indicates the valve is fully closed and

800 indicates the valve is fully open.

The microprocessor tests the ETV if required when the unit is started. Alarm Code 89 indicates the refrigeration system

pressures did not respond as expected during the test. This may be caused by a malfunction of the ETV or by a

refrigeration system problem such as low refrigerant level, a frozen expansion valve, or a restriction in suction line. The

microprocessor ignores the test results if the box temperature or the ambient temperature is below -12 C (10 F). The

ETV test can also be performed using the Service Test Mode.

Use the Gauges Menu to observe the ETV position during the ETV test. The expected ETV position observation is a

decrease followed by an increase. The suction pressure should decrease when the valve position decreases and

increase when the valve position increases.

Refer to the appropriate Diagnostic Manual for complete information about the testing and operation of the ETV.

Refer to “Electronic Throttling Valve” in Refrigeration Service Operations for removal and installation procedures.

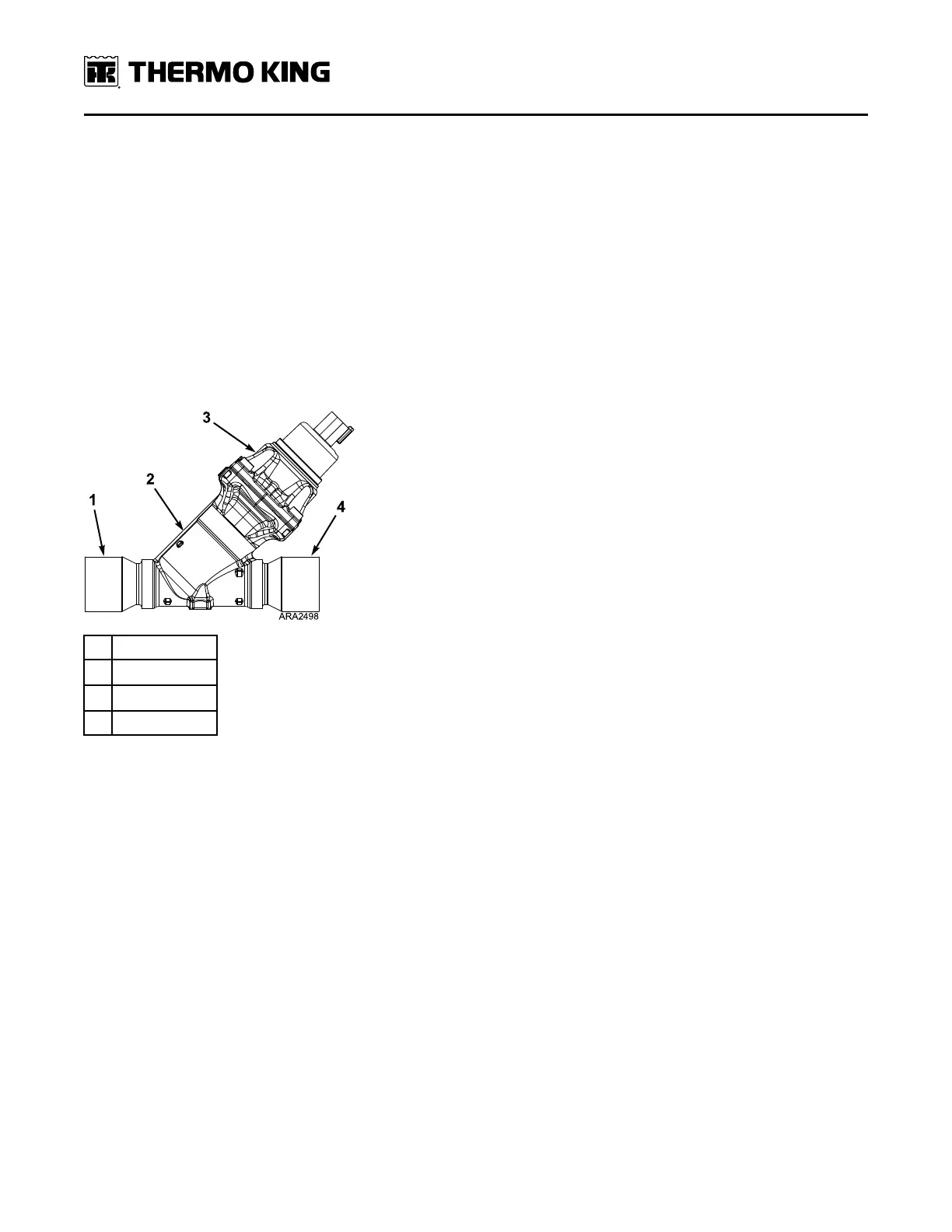

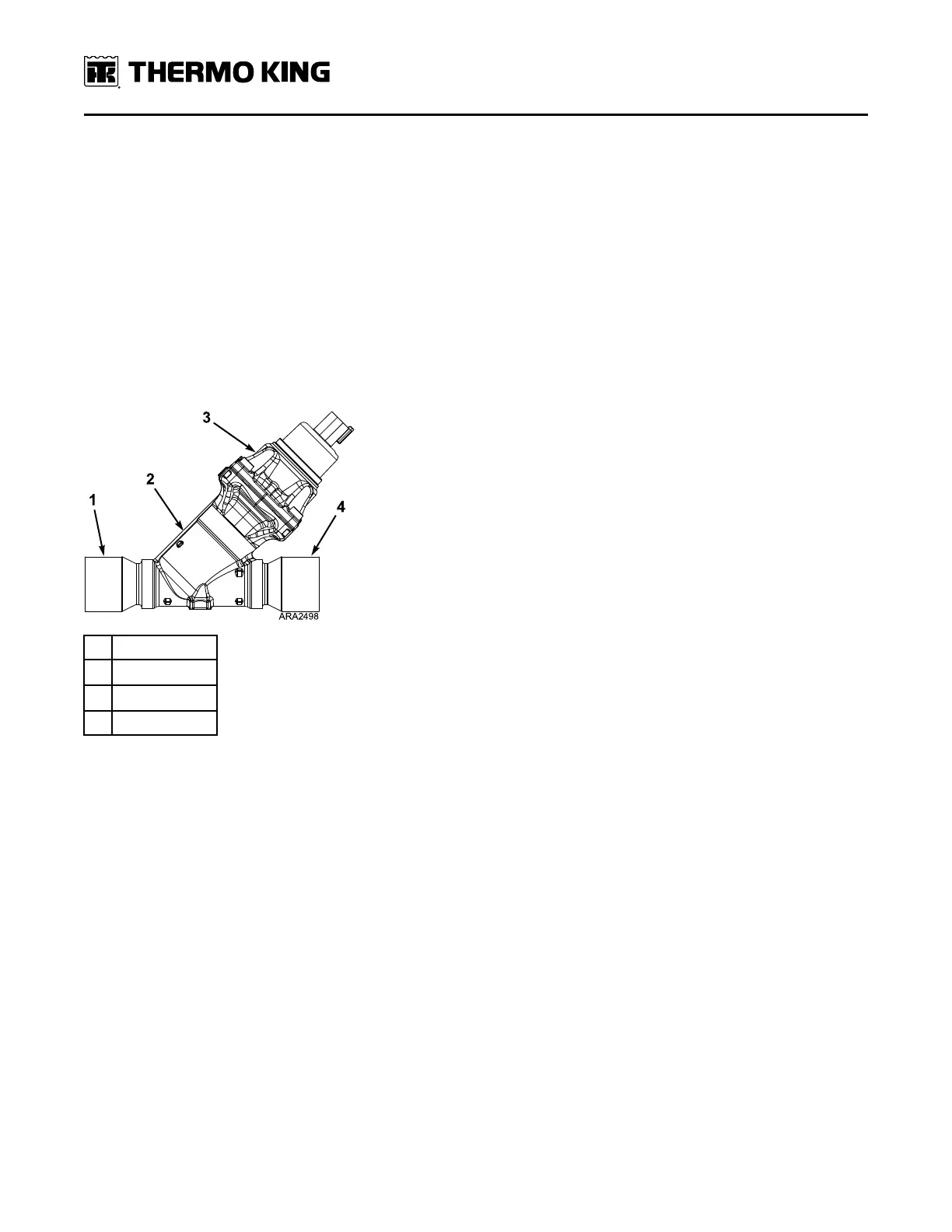

Figure 48. ETV

1. Inlet

2. Valve Body

3. Stepper Motor

4. Outlet

Pressure Transducers

The discharge pressure transducer and the suction pressure transducer supply pressure information to the

microprocessor. These pressures can be monitored with the Gauges Menu. Check the readings by comparing them to

the readings on a gauge manifold set attached to the compressor. Refer to the appropriate Diagnostic Manual for more

information about the testing and operation of the pressure transducers.

Hot Gas Bypass Valve

The hot gas bypass valve is used in conjunction with the electronic throttling valve to reduce the capacity of the unit

during modulation. This normally closed solenoid valve is located in the refrigeration line that connects the discharge

line to the hot gas line. The hot gas bypass valve is energized (opened) at full modulation. The hot gas bypass valve is

de-energized (closed) when modulation is discontinued.

Refer to the for information about testing the hot gas solenoid. See Refrigeration Service Operations for removal and

installation procedures.

RReeffrriiggeerraattiioonn MMaaiinntteennaannccee

Loading...

Loading...