MC095 - MCP-8 Control Unit Section 4 - Programming

49

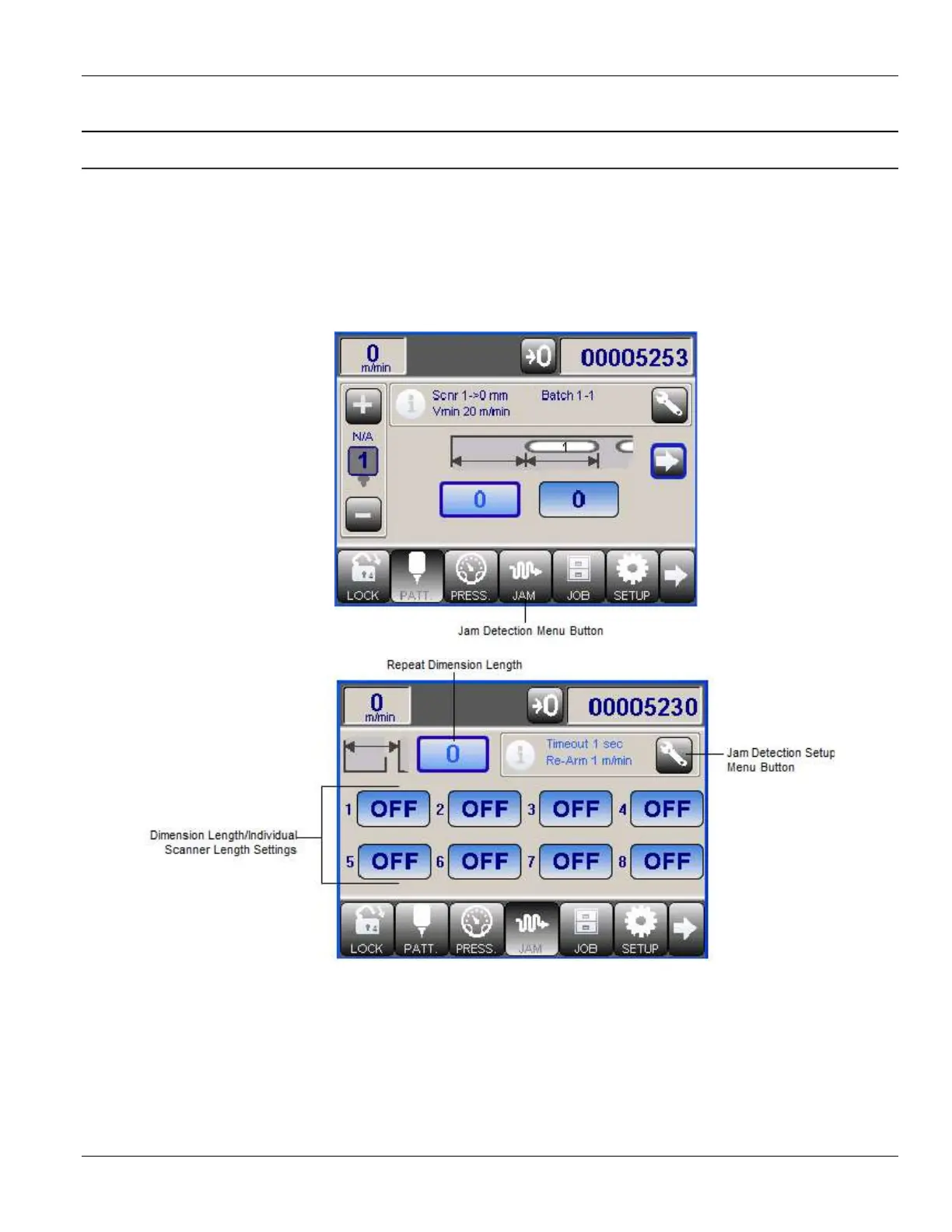

Jam Detection

Selecting the Jam Detection Menu Button opens the Jam Detection Menu.

Jam Detection, sometimes called Jam Prevention, can stop the machine before a jam occurs. Jam prevention works

by measuring the scanner activation length. If the product is double feed, then the scanner will measure the product

as being too long and stop the machine. This prevents a jam from occurring when the sheet is folded and stacked.

Jam detection can also stop the feeder, minimizing the magnitude of any jam that occurs. It can also measure if the

flap on folded boxes has been folded back correctly.

Jam Detection Menu

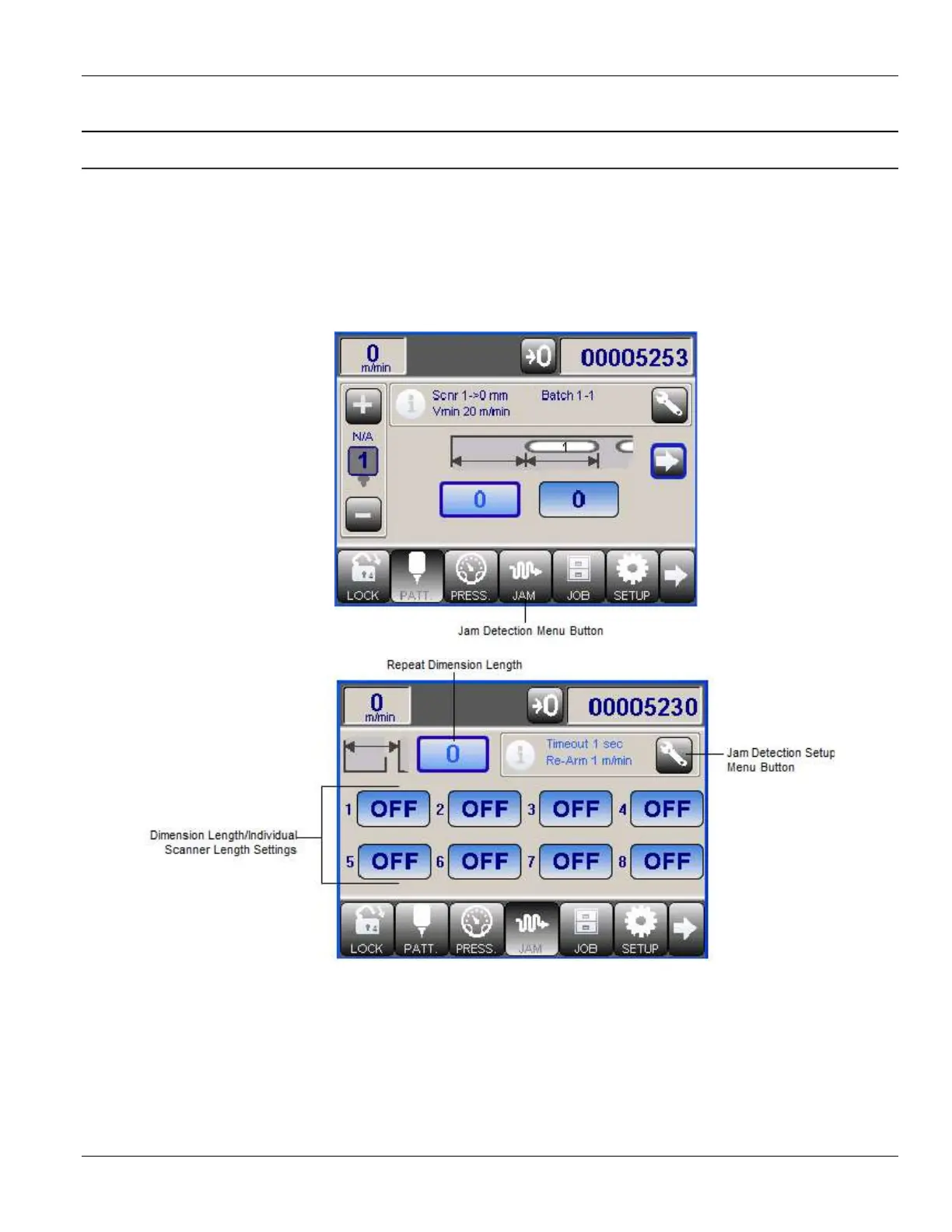

Dimension Length/Individual Scanner Length Settings:

Set an individual detection length for each active scanner. When the scanner detects any product longer than this

length, it will signal a jam. A recommended starting point would be box length plus 20%.

Repeat Dimension Length:

Use to set the Dimension Length for all scanners that are on (must press the Apply Button for this to take effect).

Jam Detection Setup Menu Button:

Opens Jam Detection Setup Menu.

Loading...

Loading...