52

Vertiv I Liebert LPC I User Manual

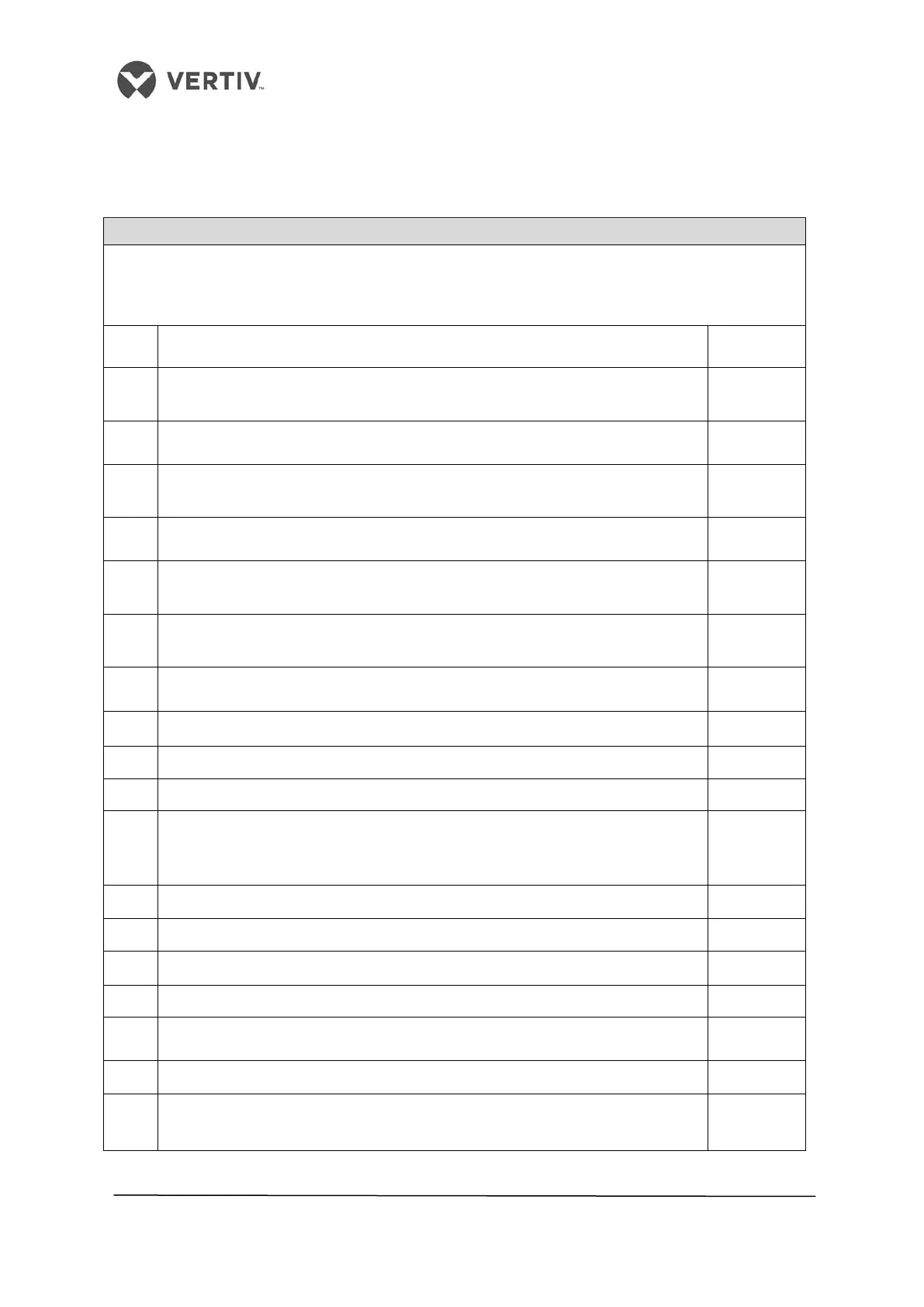

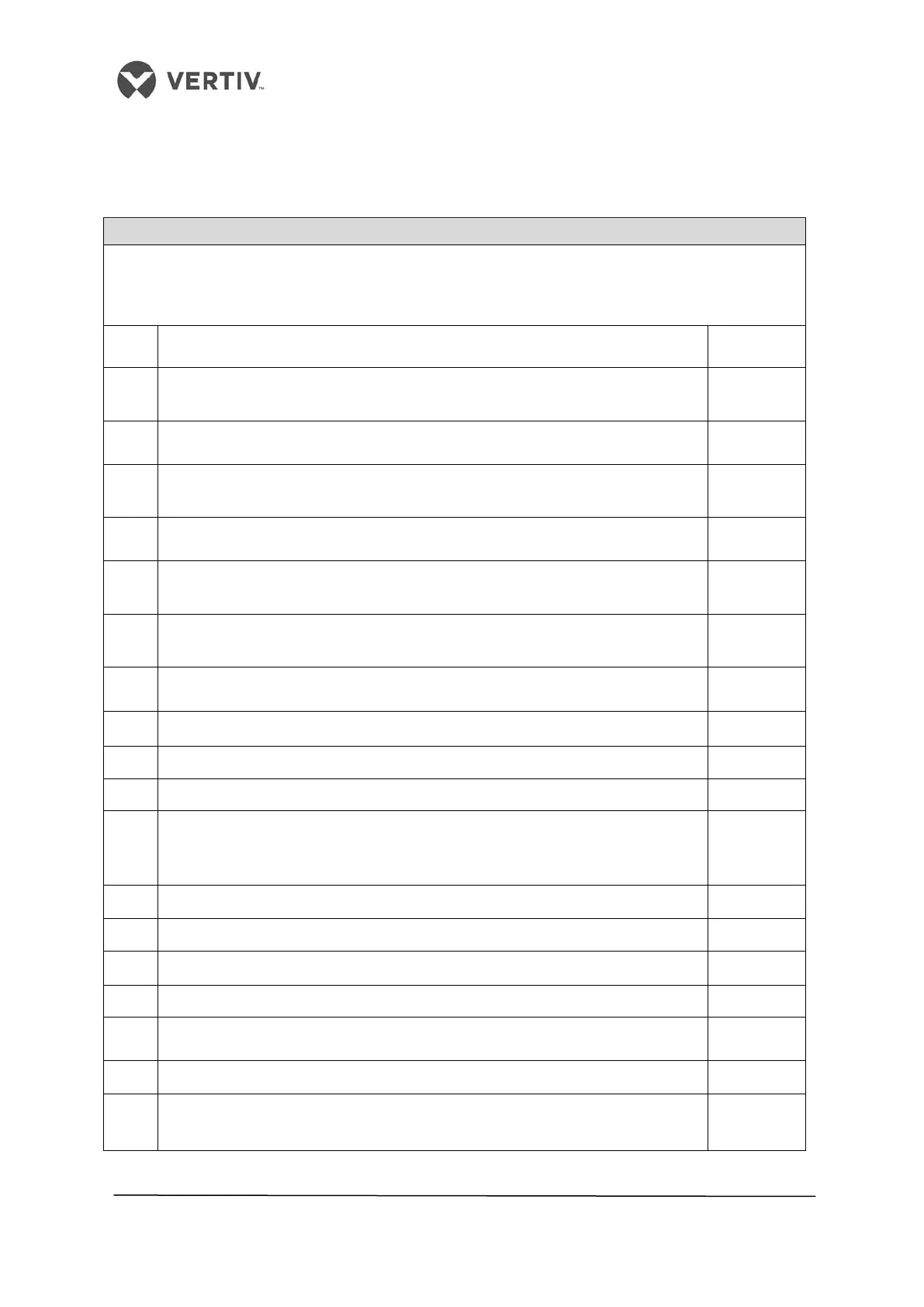

2.12.13 Pre-Commissioning Checklist

Table 2.15 shows the Pre-Commissioning checklist for the Liebert LPC Model:

Table 2.15

Pre-Commissioning Checklist

Name of Customer:

Site Location:

Details:

S. NO Indoor Unit positioning & Power cabling, CU piping, GI piping Remarks

1 Indoor units are properly spaced from the maintenance point view, minimum

gap of 6" maintained on the back side & in between of the units

2 Proper levelling of Liebert LPC indoor stand with proper grounding

3 Drip tray installed properly with silicon sealant applied on the floor stand

corner

4 Units are installed properly with rubber pads in between the unit & the stand

5 Proper earthing is provided in the mains power supply as well as body earthing

for PAC unit

6 Power cable is provided with proper sizing of the cable to suit the full capacity

of CRAC unit

7 Power supply is connected to the mains switch with proper lugs & termination

8 Mains power cable is not routed with low voltage cables

9 Soap leak test on brazing joints & also in Cu piping

10 Pressure holding time

11 Quality of copper piping laying, equidistance in between two pipes; Quality of

copper piping laying, equidistance in between two pipes, Degree bends &

12 Initial U trap provided near the indoor unit

13 U traps provided after every 7 RMT in vertical length (based on the needs)

14 Inverted U trap provided near the outdoor unit

Copper pipe with insulation are tagged properly to indicate the brazing joints

16 Proper support for refrigerant piping is configured

17 Copper pipes are painted with the proper color code

18 Additional piping kit installed in case of a vertical distance between indoor to

outdoor is more than 20RMT (or equivalent length exceed 30 Rmt)

Loading...

Loading...