13

Original Operating Instructions: K4 edition

Document version: E – 02/2020

Installing the machine

4.4 Installing the pneumatics

Risk of injuries through leaking compressed air

and lashing pneumatic hoses

Open or loose pneumatic connections can cause severe in-

juries.

h Make sure that during installation and service of the

pneumatic hoses and of the service unit compressed air

is not running through the hoses and connections.

h After installing the pneumatic hoses but before running

compressed air through the hoses and connectors, check

if the hoses are securely inserted into the correct connec

-

tors and are not damaged.

h Do not run compressed air through damaged hoses and

connectors.

The spindle may suffer bearing damage and

electrical damage if the compressed air is

contaminated

The incoming compressed air must be dry and oil-free ac-

cording to ISO

8573-1 because the service unit only serves as

an indicator for contaminated air.

Air purity according to ISO 8573-1

Solid particles Class 3 Filtration degree

better than 5 µm

for solid particles

Water content Class 4 Maximum pressure

dewpoint+3°C

Residual oil content Class 3 Maximum oil con-

tent: 1 mg/m³

h Ensure that the compressed air meets the above require-

ments.

h Connect the machine to the compressed air supply only

via the provided service unit.

The spindle requires compressed air for the following tasks:

For the opening and closing of the collet chuck during

tool change.

For the sealing air which prevents foreign bodies from

entering the spindle.

Air consumption of the machine:

approx. 50 l/min (1.8 cfm) at 6 bar (90 psi)

approx. 80 l/min (2.8 cfm) at 8 bar (120 psi)

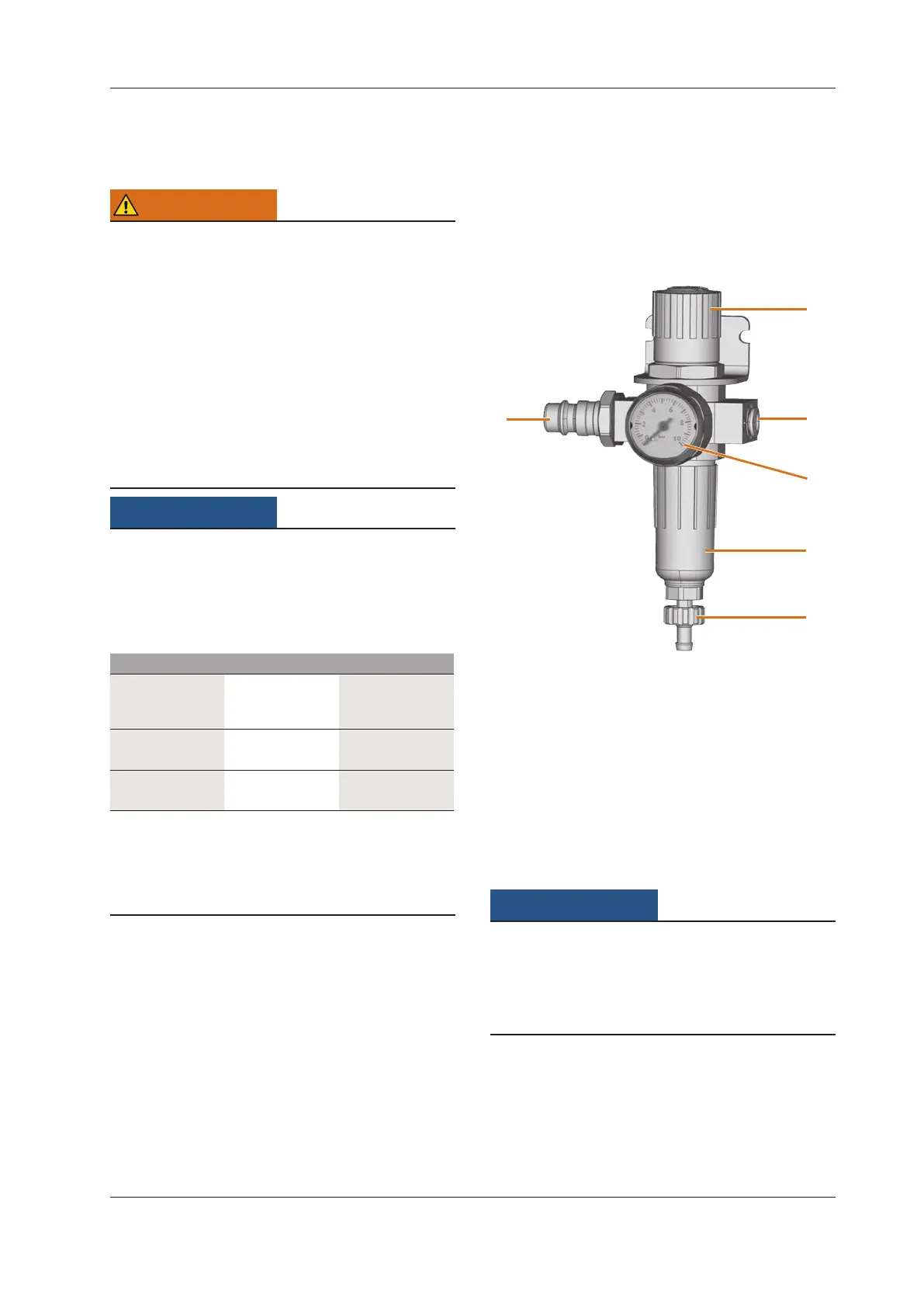

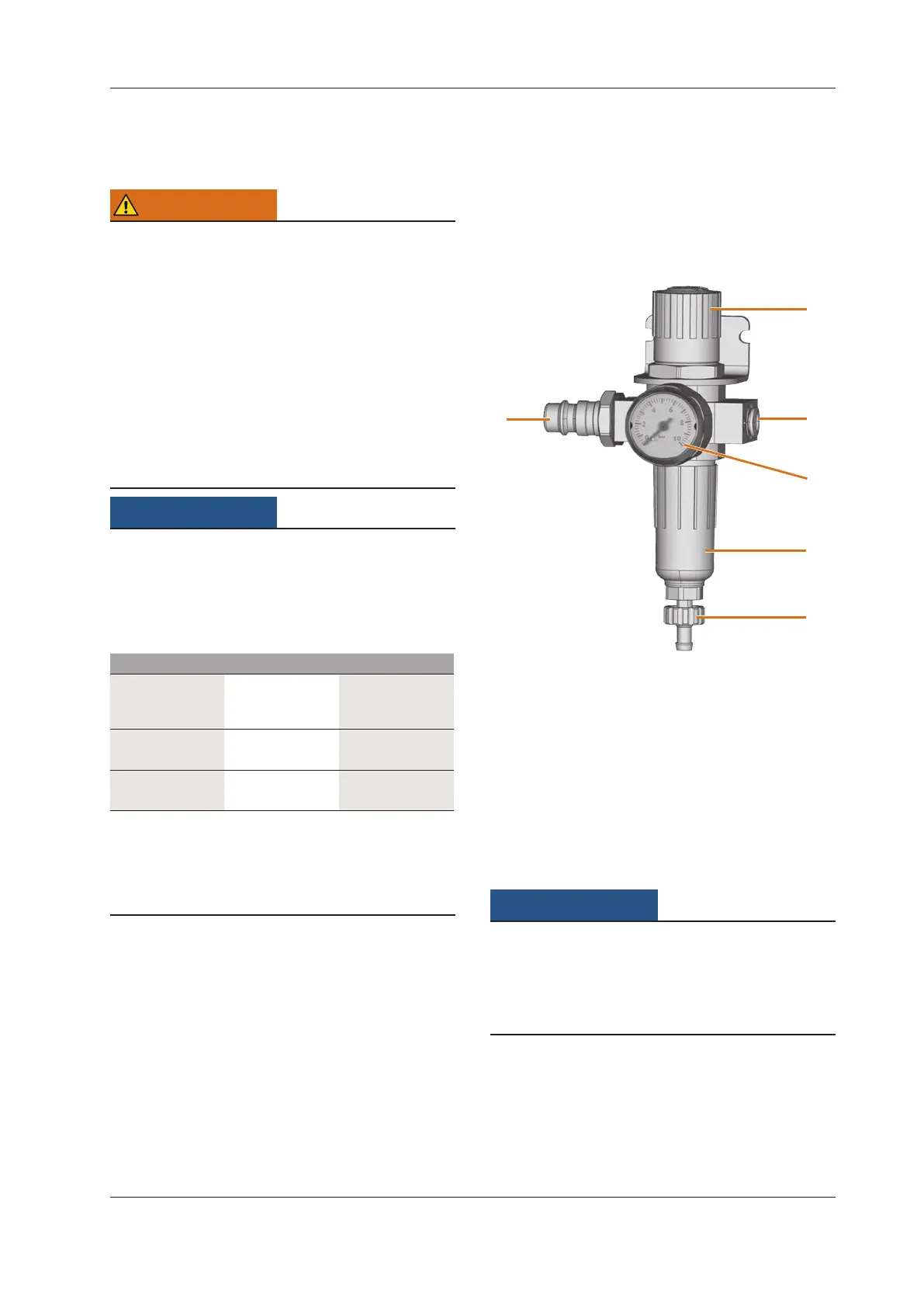

4.4.1 Overview service unit

Via the service unit you connect the Machine to your com-

pressed air supply and regulate the incoming pressure for the

machine.

1

2

3

4

5

6

[1] Rotary knob for pressure regulation

[2] Pneumatic connection to the machine (ø 6 mm)

[3] Manometer for monitoring the outgoing pressure

[4] Water separator

[5] Discharging screw

[6] Pneumatic connection for external compressed air

supply

4.4.2 Mounting the service unit on the Machine

Failure of the water separator caused by a

wrong alignment of the service unit

The service unit must always be mounted in an upright po-

sition because otherwise the water separator will not work.

h Mount the service unit in an upright position (

Fig. 6).

On the left side of the Machine are two bores which you can

use to mount the service unit on the machine.

M Mount the service unit in an upright position, using

the lens head screws provided in the bores.

Loading...

Loading...