28

Original Operating Instructions: K4 edition

Document version: E – 02/2020

Machine maintenance and cleaning

Tool breakage or incorrect results caused by

loose screws

If the blank is mounted into the blank holder too loosely, the

measurement results may become incorrect or the tool may

break during calibration.

h Tighten the screws of the xingringrmly.

M1. Mount a calibration disc into the blank holder.

S2. Mill the calibration / test specimen as described in the

documentation for the manufacturing software.

After milling the calibration / test specimen looks as

follows:

M3. Unmount the calibration / test specimen from the ma-

chine.

S4.

Follow the instructions on calibration in the documen-

tation for the manufacturing software.

M5.

After the calibration, remove the calibration tool from

the machine and keep all parts of the calibration set for

further use.

6.11 Replacing the tool magazine inserts

When the tool magazine inserts are worn, they should be re-

placed. Afterwards you must drill the tool positions into the

new inserts with the Machine.

Your Machine comes with tool magazine inserts as

spare parts and with the drill tool.

Additional inserts and drill tools are available via cus-

tomer service.

h Always replace inserts together even if only individual

inserts are worn. The machine will always drill the tool

positions for inserts.

b

The documentation for the manufacturing software

contains step-by-step instructions for drilling the in-

serts.

Belowyoundadescriptionofhowtoreplace

the tool magazine inserts in the machine.

M1. Have the tool magazine inserts ready as spare parts.

M2. Open the working chamber door.

M3. Remove all tools from the tool magazine.

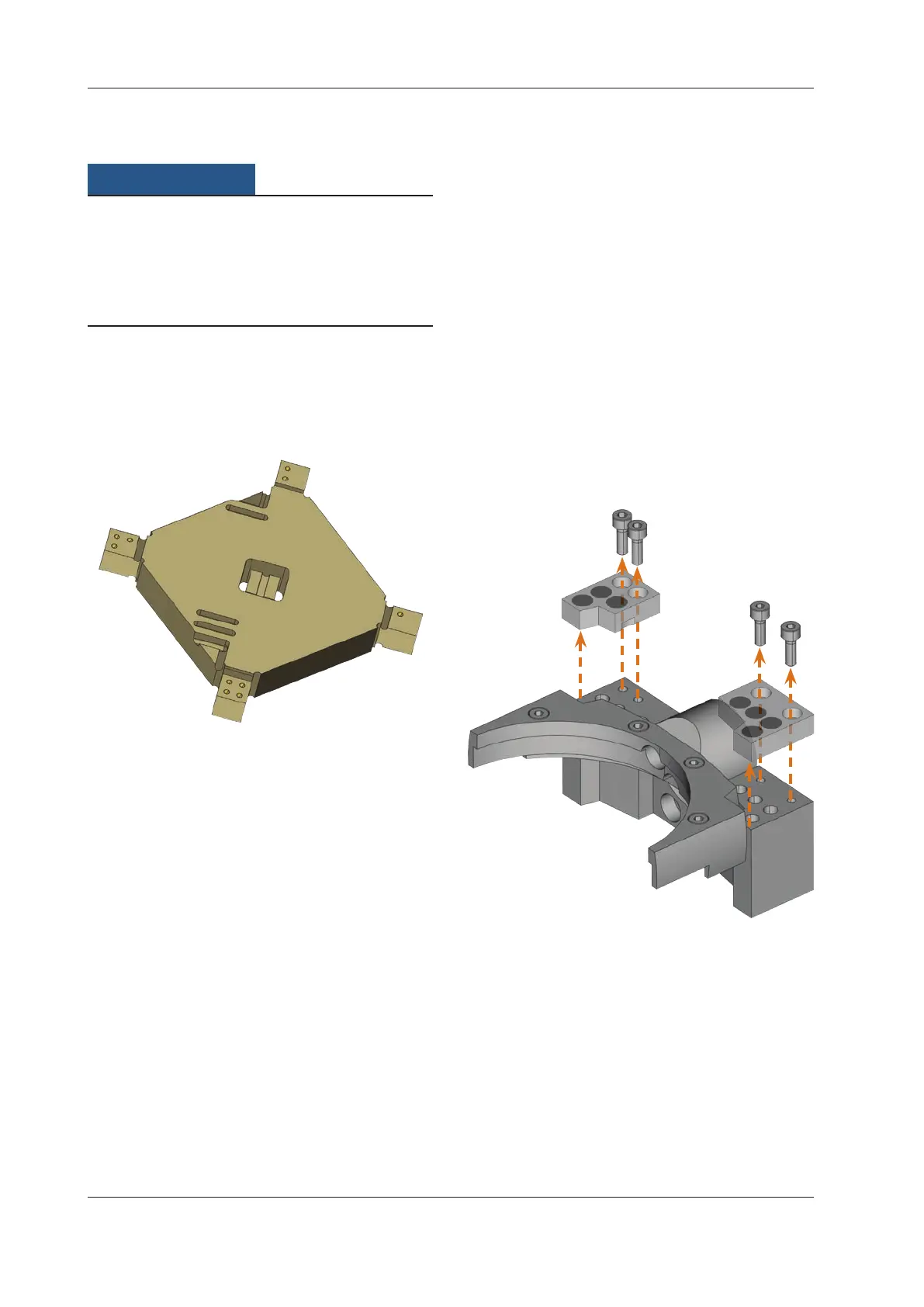

M4. Loosen the 4 screws on the upper side of the tool mag

-

azine and lift the cover (

Fig. 31).

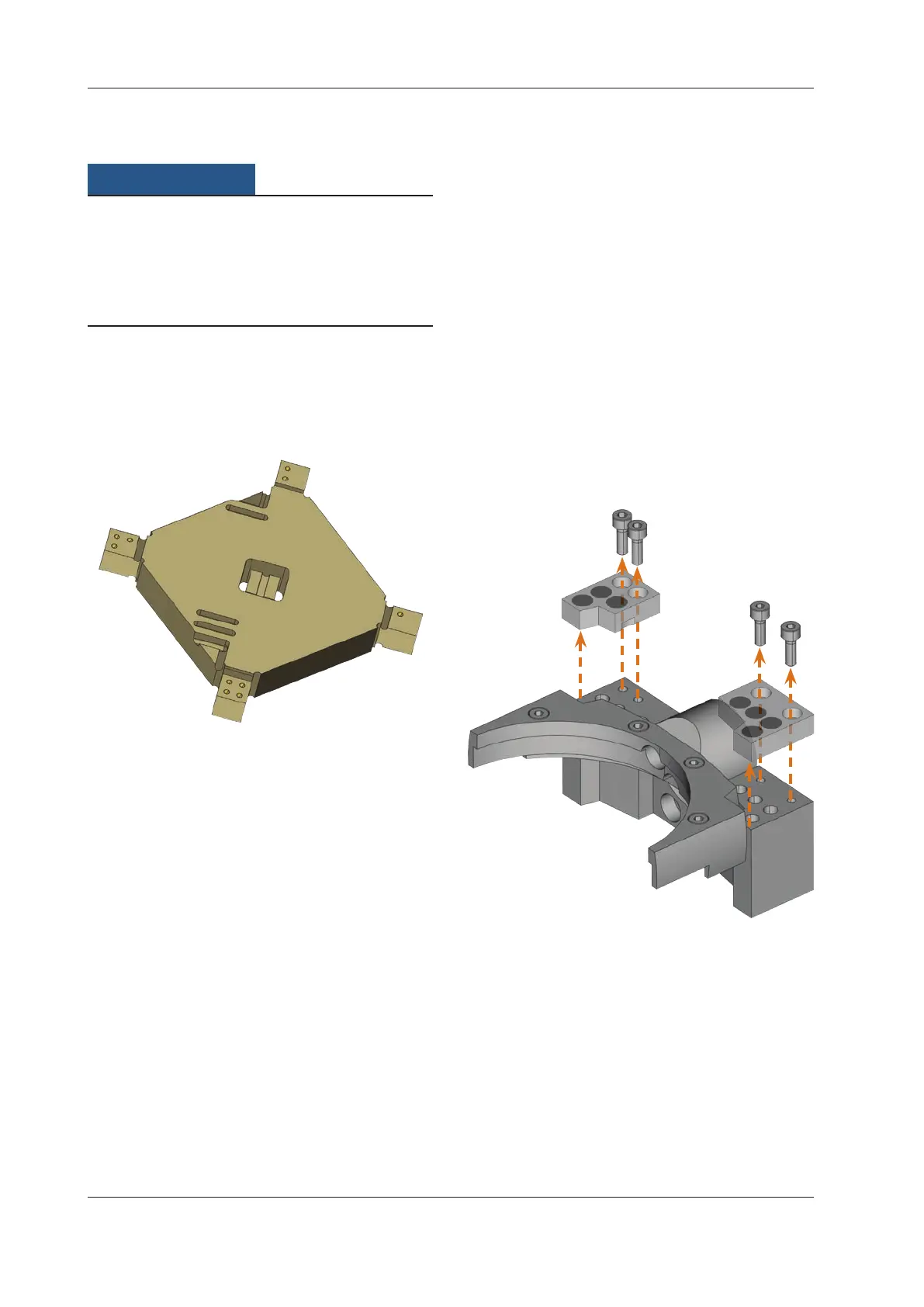

M5. Remove the 7 existing tool magazine inserts and re-

place them with new ones (

Fig. 32).

M6. Put the cover back onto the tool magazine and screw it

down with the screws that you untightened in step M4.

S7. Follow the instructions in the documentation for the

manufacturing software and drill the tool positions in

the new inserts.

Loading...

Loading...