25

Original Operating Instructions: K4 edition

Document version: E – 02/2020

Machine maintenance and cleaning

S2. Open the collet chuck with the “Release tool” function

of DentalCNC and remove the tool from the spindle if

necessary.

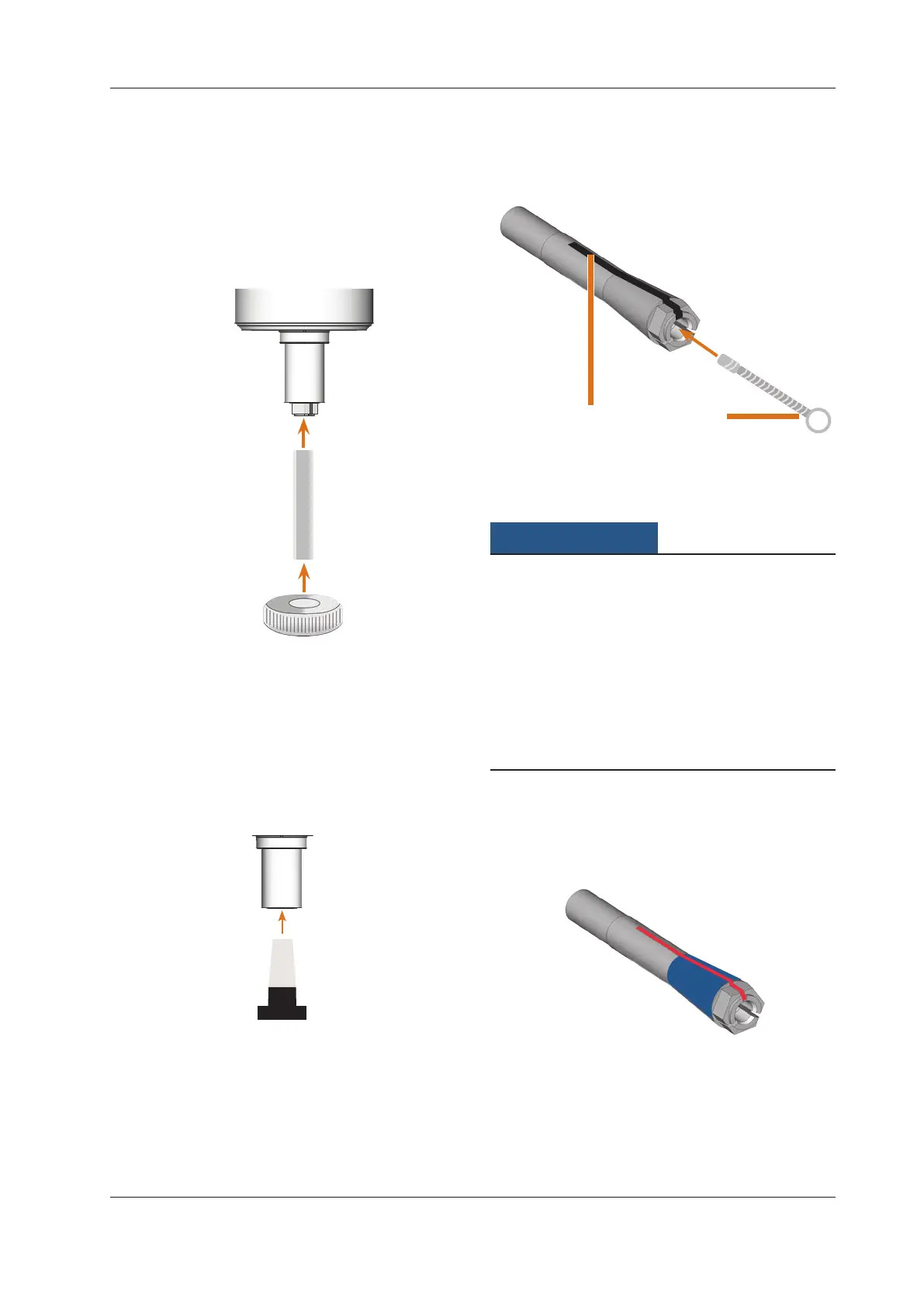

M3. Insert the measuring pin into the collet chuck and keep

holding it with one hand. With the other hand put the

knurled nut to the spindle.

1.

2.

M4. Loosen the collet chuck with the knurled nut and

unscrew the collet chuck with your hand or with the

knurled nut.

M5. Remove the measuring pin from the collet chuck. Then

put it aside within reach together with the knurled nut.

M6. Clean the inner cone of the spindle with the cleaning

cone of the service set.

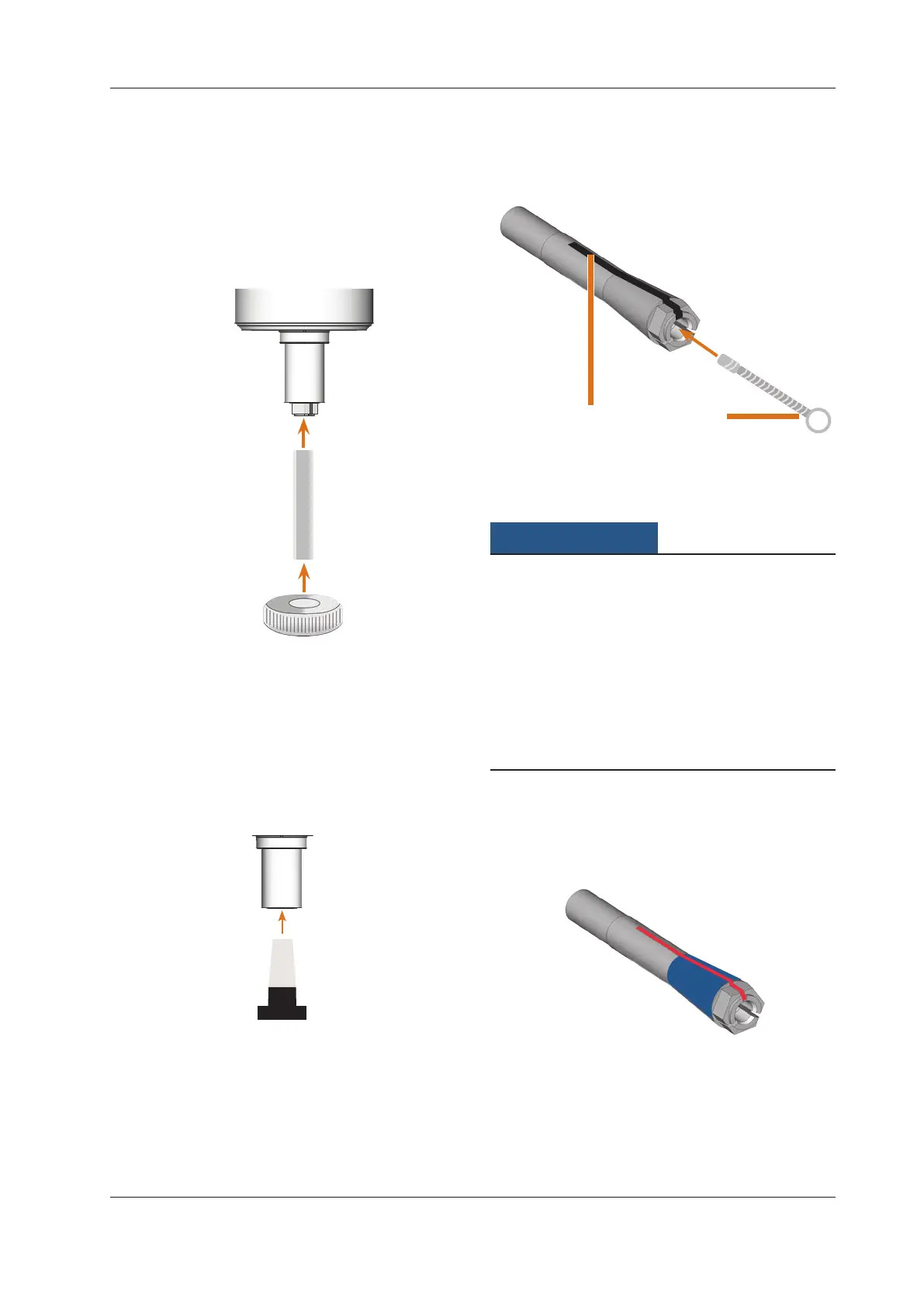

M7. If there are parts of a broken tool in the collet chuck,

remove them with the collet chuck pin.

M8. Clean the collet chuck with the brush of the service set.

1

2

[1] Longitudinal slot

[2] Cleaning brush

Damaging of the spindle when using the wrong

grease or applying the grease in a wrong way

If you use grease that is unsuitable for the spindle or if grease

gets into the longitudinal slots of the collet chuck, the spindle

may get damaged.

h Ensure that no grease gets into the longitudinal slots of

the collet chuck.

h Only use a very small, about pinhead-size amount of the

grease.

h Only use the provided collet grease of the service set.

M9. Put a small amount of the collet grease on the index

ngerandsmearitwiththethumb.

M10. Applythe smearedcolletgreaseto the anks ofthe

collet chuck.

Loading...

Loading...