SHB 28Z3 EN – Edition 2.0 * 28z3s210.fm 2-7

Specifications

Galvanised and dry surface (O-ring slightly oiled). Torque tolerance: -10 %

Values determined empirically and to be applied as approximate figures.

Torque tolerance: – 10 %; countermaterial: steel/aluminium

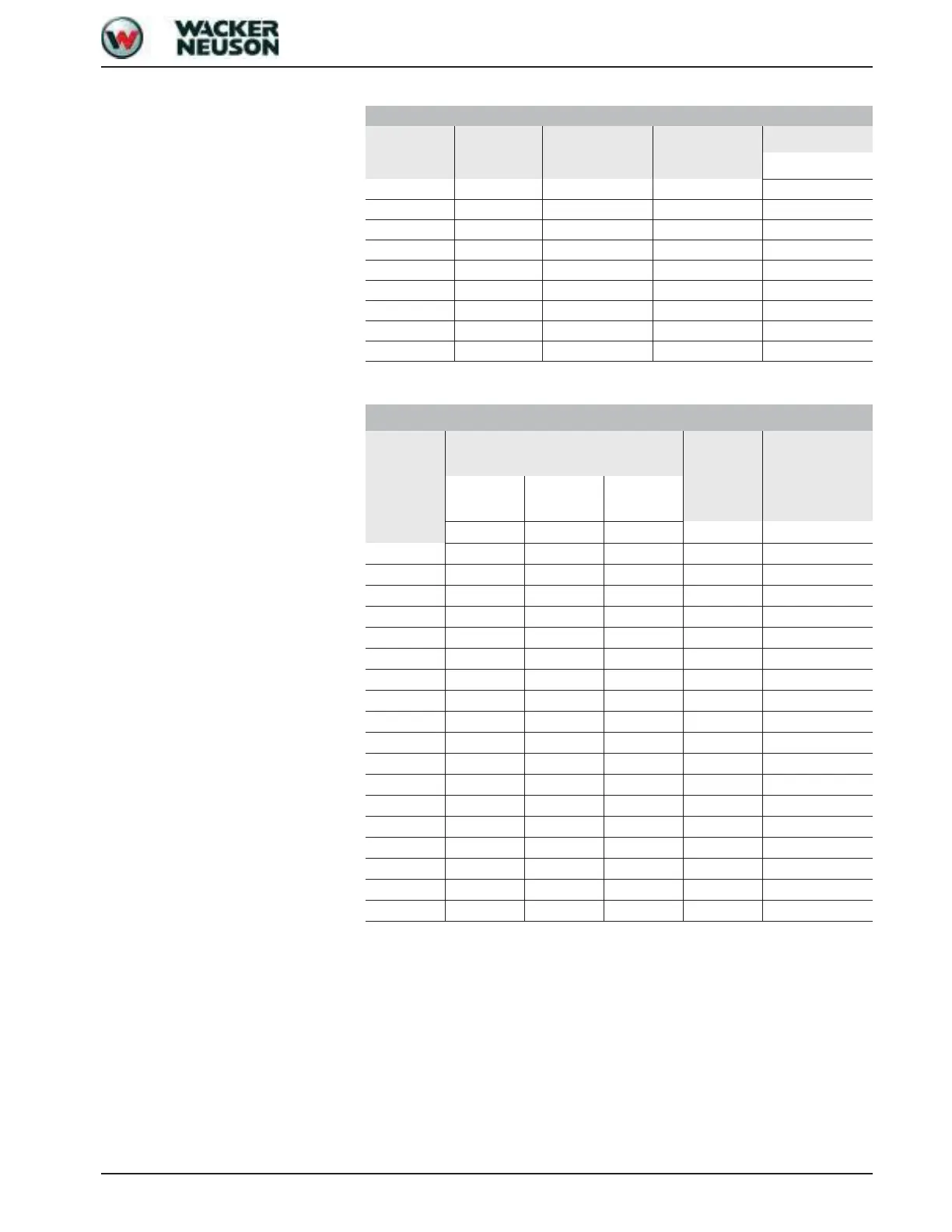

Metric hose fittings for hydraulic applications (heavy execution, DKOL)

Nominal Ø Outer Ø Thread Wrench size

Tightening torque

Nm (lbs/ft)

05 8S M16X1.5 WS 19 40 (29.5)

06 10S M18X1.5 WS 22 50 (36.8)

08 12S M20X1.5 WS 24 60 (44.3)

10 14S M22X1.5 WS 27 75 (55.3)

12 16S M24X1.5 WS 30 90 (66.4)

16 20S M30X2 WS 36 100 (73.8)

20 25S M36X2 WS 41 180 (132.8)

25 30S M42X2 WS 50 270 (199.1)

32 38S M52X2 WS 60 400 (295)

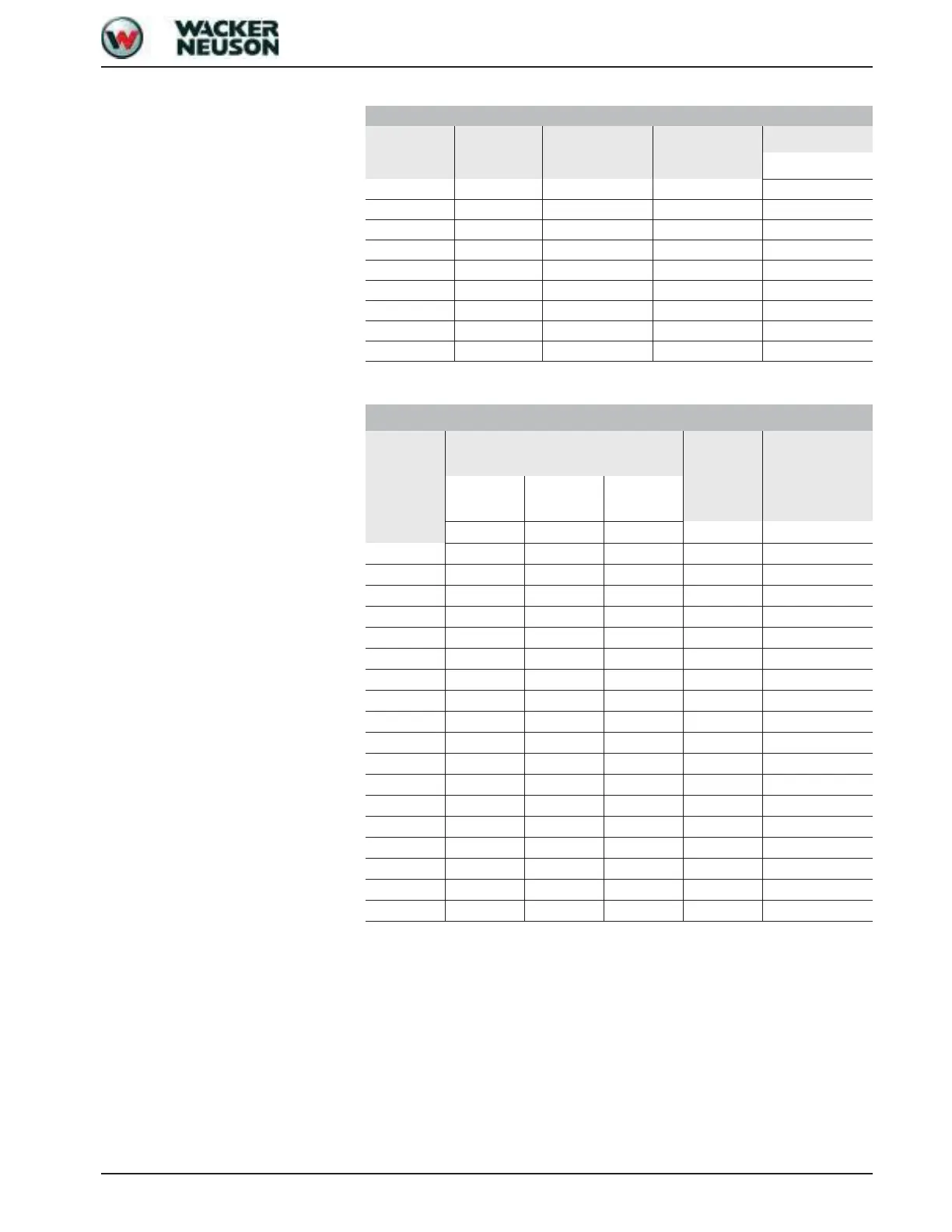

Screw connections with various seals for hydraulic applications (light execution)

Thread

Straight pipe fitting with thread and

screwed plug

Non-return

valve with

elastic seal

Identification aid

outside Ø

Sealing

washer

Elastic seal O-ring

Nm (lbs/ft) Nm (lbs/ft) Nm (lbs/ft) Nm (lbs/ft) mm (”)

M10X1.0 9 (7) 18 (13) 15 (11) 18 (13) 10 (0.4)

M12X1.5 20 (15) 25 (18) 25 (18) 25 (18) 12 (0.5)

M14X1.5 35 (26) 45 (33) 35 (26) 35 (26) 14 (0.55)

M16X1.5 45 (33) 55 (41) 40 (30) 50 (37) 16 (0.6)

M18X1.5 55 (41) 70 (52) 45 (33) 70 (52) 18 (0.7)

M22X1.5 65 (48) 125 (92) 60 (44) 125 (92) 22 (0.9)

M27X2.0 90 (66) 180 (133) 100 (74) 145 (107) 27 (1.0)

M33X2.0 150 (111) 310 (229) 160 (118) 210 (155) 33 (1.3)

M42X2.0 240 (177) 450 (332) 210 (155) 360 (266) 42 (1.7)

M48X2.0 290 (214) 540 (398) 260 (192) 540 (398) 48 (1.9)

G1/8A 9 (7) 18 (13) 15 (11) 18 (13) 9.73 (0.38)

G1/4A 35 (26) 35 (26) 30 (22) 35 (26) 13.16 (0.52)

G3/8A 45 (33) 70 (52) 45 (33) 50 (37) 16.66 (0.66)

G1/2A 65 (48) 90 (66) 55 (41) 65 (48) 20.96 (0.83)

G3/4A 90 (66) 180 (133) 100(74) 140 (103) 26.44 (1.04)

G1A 150 (111) 310 (229) 160 (118) 190 (140) 33.25 (1.31)

G1 1/4A 240 (177) 450 (332) 210 (155) 360 (266) 41.91 (1.65)

G1 1/2A 290 (214) 540 (398) 260 (192) 540 (398) 47.80 (1.88)

Loading...

Loading...