3-4 SHB 28Z3 EN – Edition 2.0 * 28z3s310.fm

Maintenance

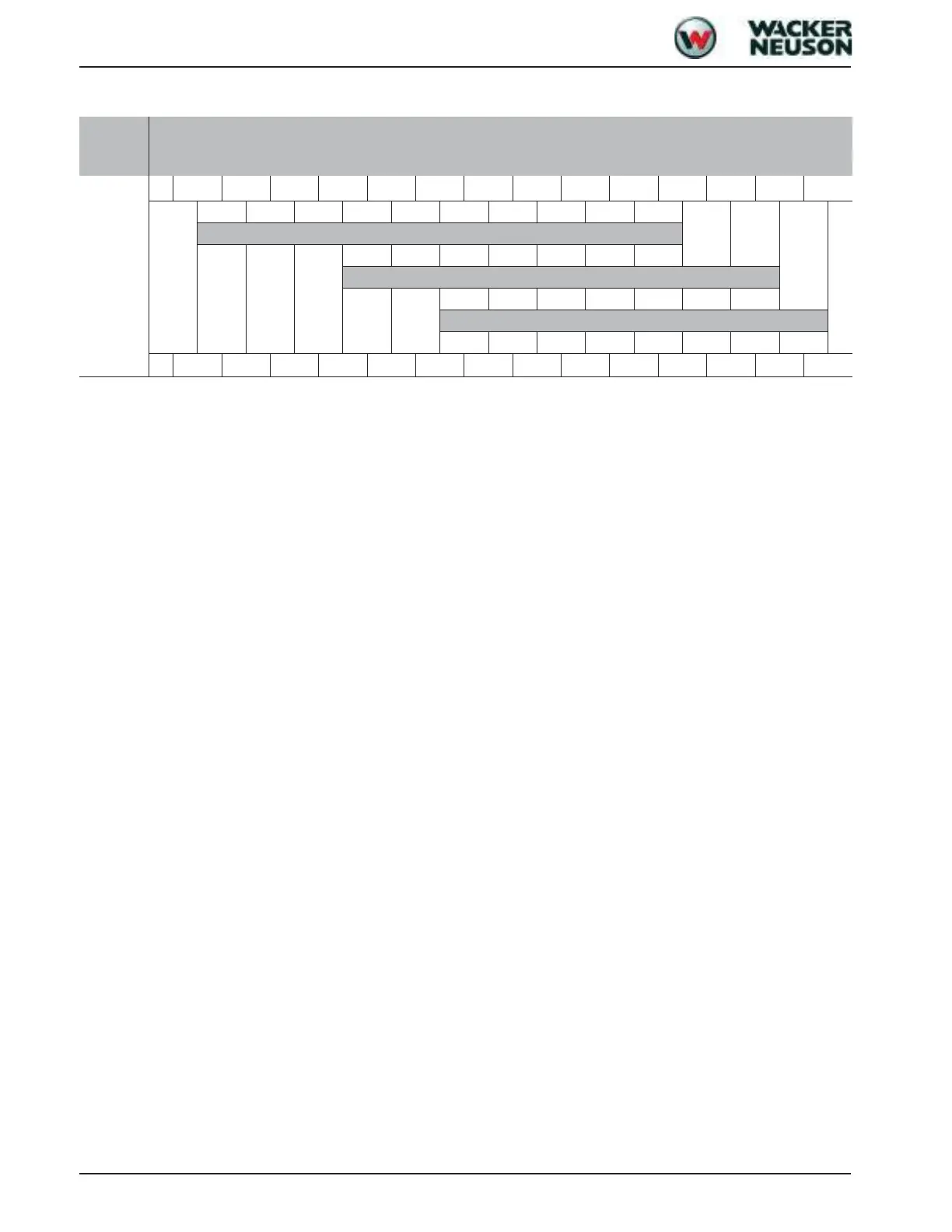

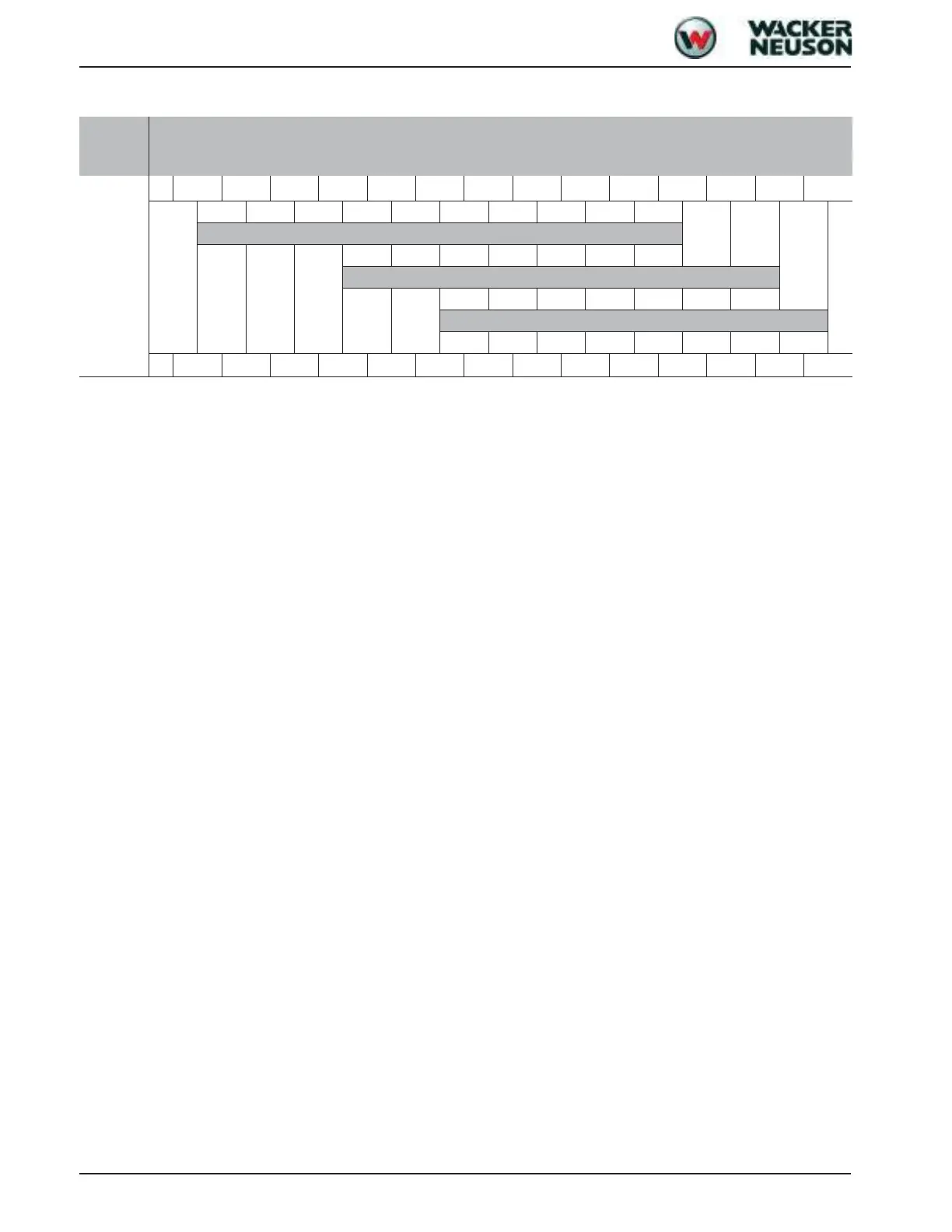

Oil grades for the hydraulic system, depending on temperature

Hydrau-

lics oil

grade

Ambient temperature (C°/°F)

HVLP

1

°C

-20-15-10-5 0 5 1015202530354050

ISO VG32

ISO VG46

ISO VG68

°F

-4 5 14233241505968778695104

122

1. According to DIN 51524 section 3

Loading...

Loading...