SHB 28Z3 EN – Edition 2.0 * 28z3s810.fm 8-27

PowerTilt PTS06

8.20 Lubrication and tests

☞ For purposes of lubrication or testing, connect the PowerTilt swivel device either to a

hydraulics test bench or to a portable pump.

☞ Fasten the PowerTilt swivel device firmly in order to avoid any movement.

Lubrication

☞ Fit the grease nipples, grease decompression valves and covers.

☞ Before putting the PowerTilt swivel device into operation, apply lithium grease to the

plug seals and pressure discs.

☞ Use a grease gun to lubricate the seals and pressure discs at grease nipples h or the

lubrication connection at the base of the PowerTilt swivel device until grease escapes

from the grease decompression valves j.

☞ Slowly put the PowerTilt swivel device into operation and lubricate again as required.

Let the device carry out 20 – 30 cycles during the test, to test the machine for leaks and

correct rotation.

Test for internal leaks

☞ Connect a 350 bar (5076 psi) pressure gauge to the hydraulic line to P1. Create pres-

sure at P1 until the rotating shaft touches the internal or external limits.

Notice!

Otherwise hydraulic oil escapes at P2 in very little time.

☞ Remove and close the hydraulic line at P2. Create a pressure of 175 bar (2538 psi) at

P1. Check for leaks at P2 and near the main shaft and end-cap seals.

Notice!

Leaks are a sign of incorrectly installed parts.

☞ Connect a hydraulic line to P2 and create pressure as in step 1.

☞ Check for leaks at P1 and near the main shaft and end-cap seals (see step 2).

Fig. 76: Connecting rod and head screws

Fig. 77: Lubricant

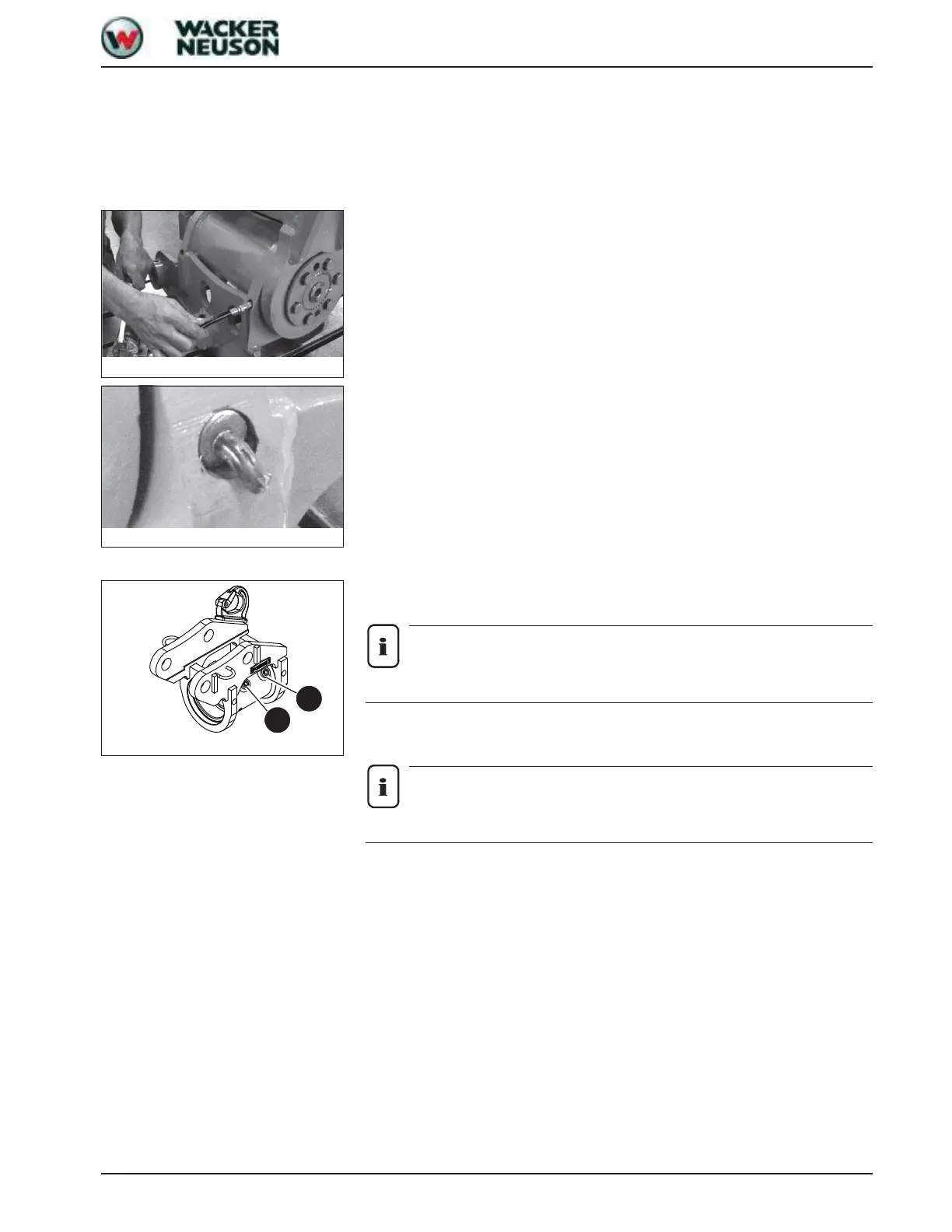

Fig. 78: Hydraulic connections PTS06

P1

P2

Loading...

Loading...