3-52 SHB 28Z3 EN – Edition 2.0 * 28z3s314.fm

Maintenance

Use a suitable container to collect the grease as it flows out and dispose of it in

an environmentally friendly manner.

3.19 Maintenance of attachments

Notice!

Correct maintenance and service is absolutely necessary for smooth and continu-

ous operation, and for an increased service life of the attachments. Observe the

lubrication and maintenance instructions in the Operator's Manuals of the attach-

ments.

3.20 Lubrication points

Parking the machine

☞ Stop the machine on firm, level and horizontal ground.

☞ Lower the boom.

☞ Lower the stabiliser blade to the ground.

☞ Stop the engine.

☞ Remove the key and carry it with you.

☞ Move control levers 1 and 2 in all directions repeatedly.

☞ Fold the control lever base up.

☞ Do not allow anyone to stay in the cab, and close the doors and the engine cover.

☞ Perform maintenance work.

Notice!

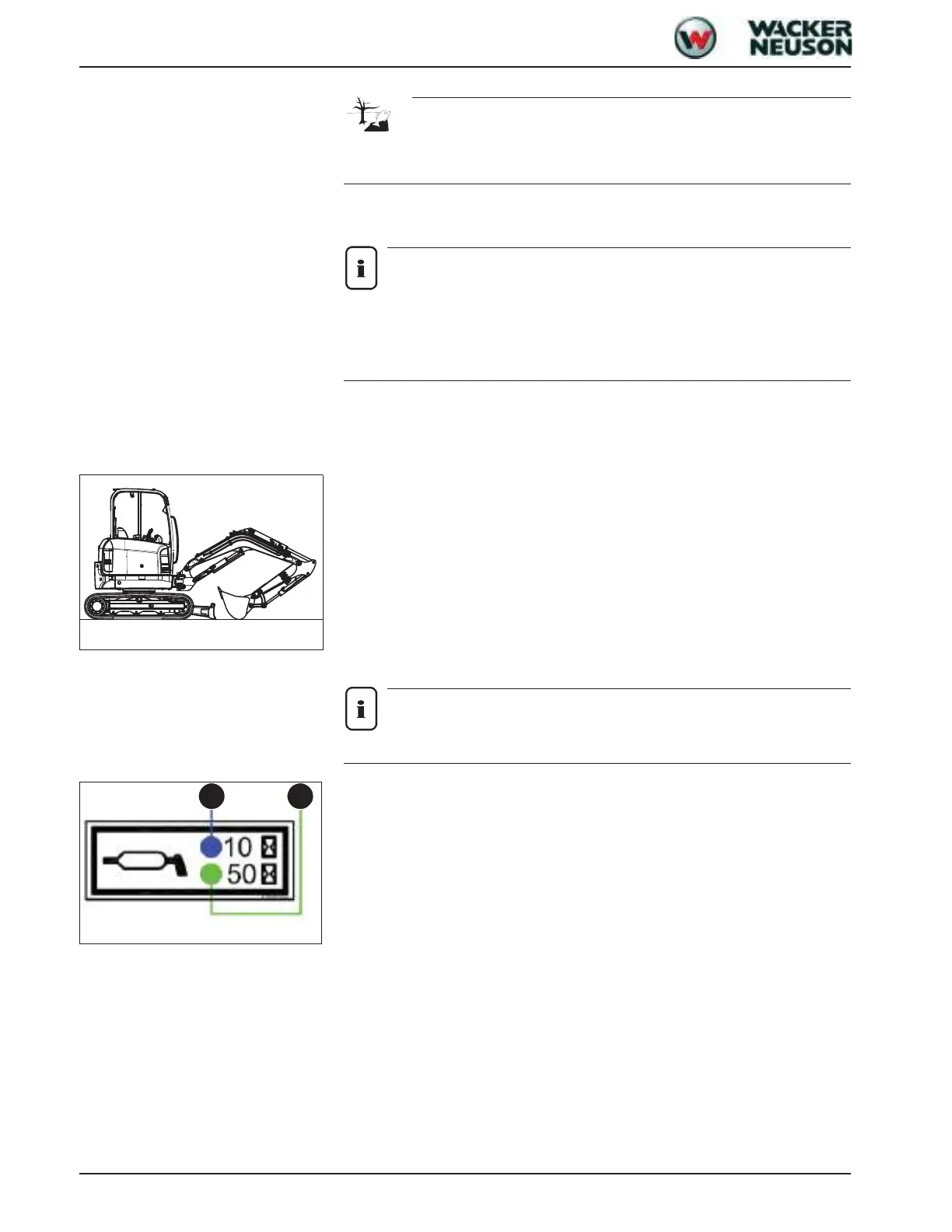

Keep the lubrication points clean and remove ejected grease.

A grease type listed in the specifications must be applied to all lubrication points listed

– see chapter 3.1 Fluids and lubricants on page 3-2.

• Lubrication points A with blue caps

☞ Apply grease daily

• Lubrication points B with green caps

☞ Apply grease once a week

Lubricate all mechanical pivots on the machine (such as door hinges, joints) and

fittings (such as door arresters) at regular intervals even if

they are not listed in the lubrication plan.

Fig. 64: Transport position

Fig. 65: Lubrication recommendation

A B

Loading...

Loading...