BA 50Z3/6003 en – Edition 4.3 * 5003b520.fm 5-23

Maintenance

Maintenance

The maintenance work listed below must be performed in addition to the maintenance

work stated in the Operator’s Manual of the machine.

Daily maintenance

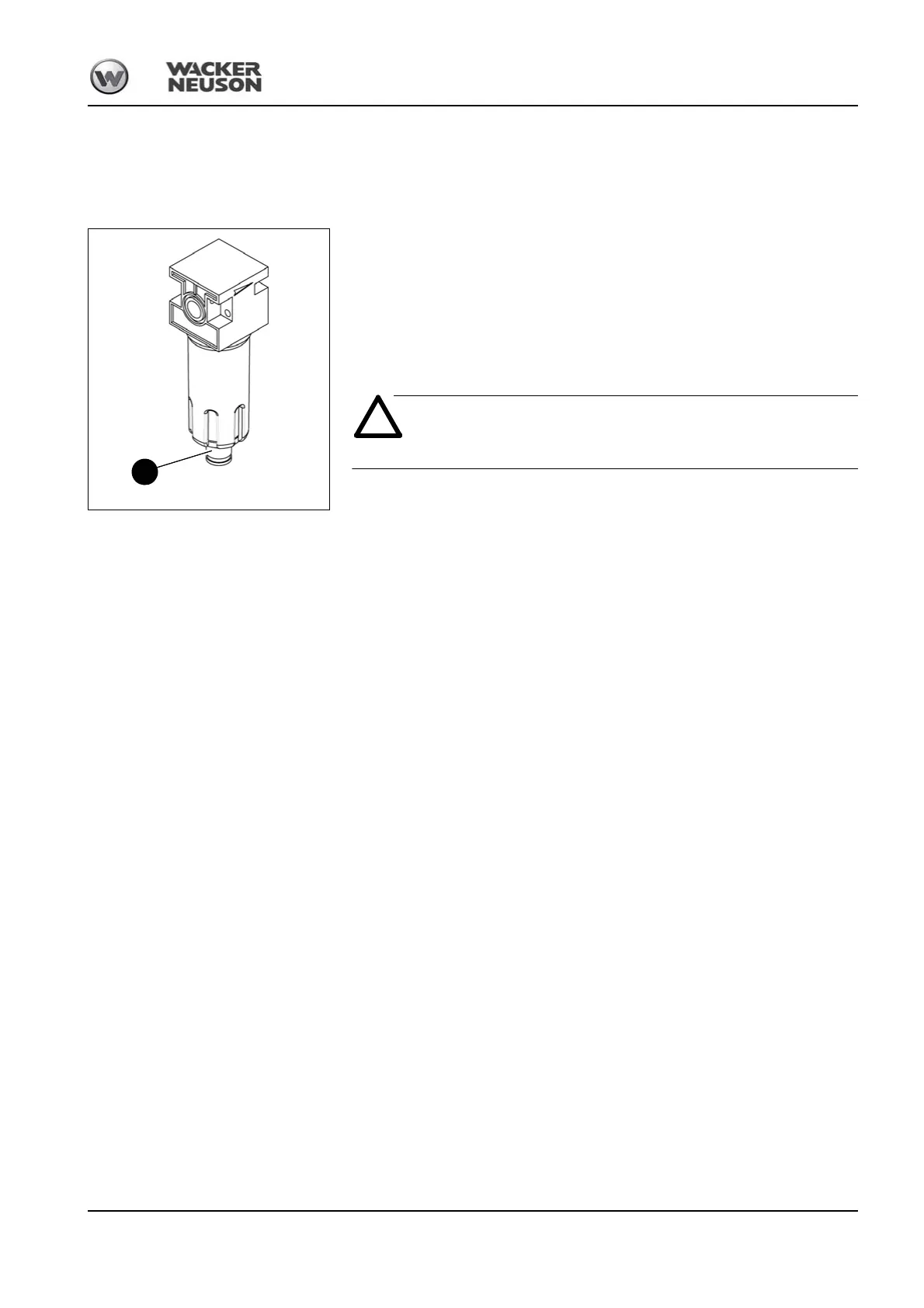

• Drain the water from the condensate trap by opening valve A.

• Ensure that there is no soot on the exhaust pipe *.

• Check whether all indicator lights on the display illuminate when switching on ignition.

• Check the plausibility of the temperature values.

• Check the plausibility of the pressure values. To this effect, open the valve on the

condensate trap after the machine is warm and read the pressure off the display, then

close the valve and read off the pressure again. The pressure must be higher with a

closed valve, otherwise there is an error in the system.

Once maintenance is over, ensure that condensate trap valve A is closed.

Every 50 h

• Visual check of the particulate filter system (wiring, pressure line, particulate filter,

insulating mat, diesel fuel lines etc.).

• Ensure that the clips on the diesel particulate filter are fastened firmly.

• Check the fastening screws of the input pipe on the exhaust manifold for tightness.

• Ensure that there is no soot on the end pipe of the particulate filter*.

Once a year/every 500 h

• Have the system components checked for correct function by an authorized service.

☞ Contact an authorized workshop.

Statutory maintenance work

• Get in touch with an authorized workshop for information on possible country-specific

statutory maintenance work.

As required

• If the maximum authorized limit for the exhaust gas back pressure is exceeded, stop

the machine and regenerate the diesel particulate filter externally.

Contact an authorized workshop.

• During fuel combustion in the diesel engine, part of the engine oil is burnt, too, and

produces ashes that are deposited in the diesel particulate filter. These ashes contam-

inate the diesel particulate filter by and by and prevent the absorption of soot. This

causes the machine to constantly work at the upper limit of the exhaust gas back

pressure. As soon as this is the case**, the diesel particulate filter must be cleaned

externally. Contact an authorized workshop.

* Diesel fuel injection can create a slight black cloudiness at the end pipe, however, this does not affect the function of the

system whatsoever.

** The time this condition comes into being greatly depends on the application, the user, the machine, and the oil and fuel used.

A

Fig. 286: Condensate trap

Loading...

Loading...