SAFETY REGULATIONS

1.21 SETUP ON AN UNEVEN SURFACE

The front end must always point downwards in order to avoid

sliding away.

If possible do not use the unit in a vertical position with the

suction tube on an inclined surface since the unit tends to

wander through the resulting vibrations.

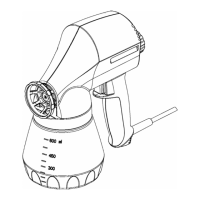

2 GENERAL VIEW OF APPLICATION

2.1 APPLICATION

NESPRAY PLUS was developed as part of a research project in

cooperation with the Caparol company relating to the mist-

free atomisation of dispersions.

The equipment technology including the accessories included

in the scope of delivery and the NespriTec paints form a unit

which enables mist-free spraying, e.g. on facades.

The device must only be used in conjunction with these dis-

persion paints, in order to achieve mist-free application.

Your Caparol specialist dealer will be pleased to help you.

The unit performance is conceived so that its use is possible

on building sites for small- to large-area dispersion work.

In principle the components specied in the accessories range

(nozzles, inline roller, delivery guns) can also be used with the

device, but mist-free application within the scope of the NE-

SPRAY system may then no longer be possible.

2.2 COATING MATERIAL

The NespriTec paints are supplied by the Caparol company in

ready-to-spray quality.

Additional dilution and stirring will result in

loss of the optimal properties for mist-free

spraying and should be avoided.

The unit is able to process coating materials with up to

25,000 mPas. Heating in the hose reduces the viscosity at the

tip considerably so that even atomizing becomes possible.

If the paint needs to be stirred for other rea-

sons, ensure that no air bubbles are stirred in.

Air bubbles disturb when spraying and can,

in fact, lead to interruption of operation.

2.2.1 FILTERING

Sucient ltering is required for fault-free operation. To this

purpose the unit is equipped with a suction lter (Item 1), a

high-pressure lter (Item 2) and an insertion lter in the spray

gun (Item 3). Regular inspection of these lters for damage or

soiling is urgently recommended.

2.2.2 COATING MATERIALS WITH SHARPEDGED

ADDITIONAL MATERIALS

These particles have a strong wear and tear eect on valves

and tips, but also on the heating hose and spray gun. This im-

pairs the durability of these wearing parts considerably.

1.22 WORK AT ELECTRICAL COMPONENTS

Unplug the power plug from the outlet before carrying out

any repair work.

1

2

3

Loading...

Loading...