Serie 750, 753Planning

40 System manual | Version: 3.0.2

• e!COCKPIT

e!COCKPIT is an integrated development environment that supports every automation

task, from hardware configuration and programming, to simulation and visualization, to

commissioning – an all-in-one software package.

• WAGO Smart Designer Product Configurator

The Smart Designer product configurator enables true 3D configuration of WAGO’s

electrical interconnect and automation components, including the WAGO-I/O-SYSTEM

750, circuit boards and terminal blocks. With this tool you can, among other things,

configure a node of the I/O system and calculate the approximate power requirement.

• WAGO-I/O-CHECK

Application for operating and displaying a node from the WAGO 750 I/O-SYSTEM

Coding

Multi-part I/O modules from the WAGO I/O-System can be equipped with coding keys to

prevent mismatching when connecting the individual module parts.

For additional information see: 8Assembling/Disassembling Components [}48].

System Supply Power Requirement: Example Calculation

The example calculation is based on the following node structure:

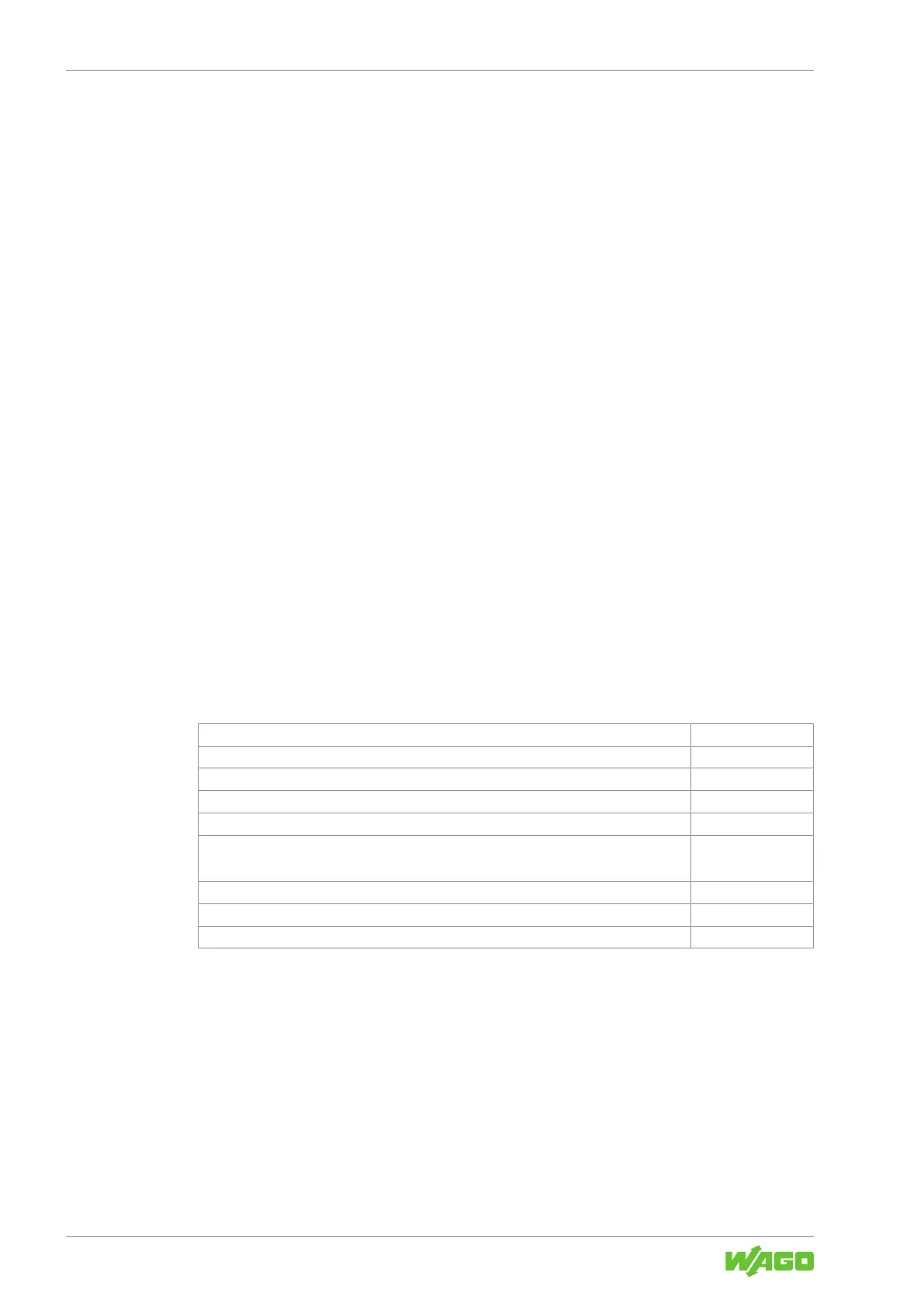

• Head station

• 5 × 16-channel digital input module

• 5 × 16-channel digital output module

• 11 × 8-channel analog input module

• 10 × 8-channel analog output module

• 2 × relay module

• I/O module ...

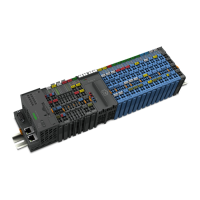

Table10: Power Requirement: Example Calculation

Head station 1,700 mA

5 × 16-channel digital input module (25mA) − 125mA

5 × 16-channel digital output module (40mA) − 200mA

11 ×8-channel analog input module (69mA) − 759mA

10 × 8-channel analog output module (61mA) − 610mA

Remaining total system supply current

At this point, an additional supply module must be used!

6 mA

Supply module 2,000mA

2 × relay module (100mA) − 200mA

I/O module ... − ...

Field Supply Power Requirement: Example Calculation

The field supply layout must be handled in the same way as the system supply. Addi-

tional supply modules may be needed. Detailed product information is available in the re-

spective & Product Manual.

Determining Power Loss

Power loss depends on the node structure and the applied field signals. To roughly deter-

mine power loss, use:

• Head station: 3W

Loading...

Loading...