Serie 750, 753 Planning

System manual | Version: 3.0.2 31

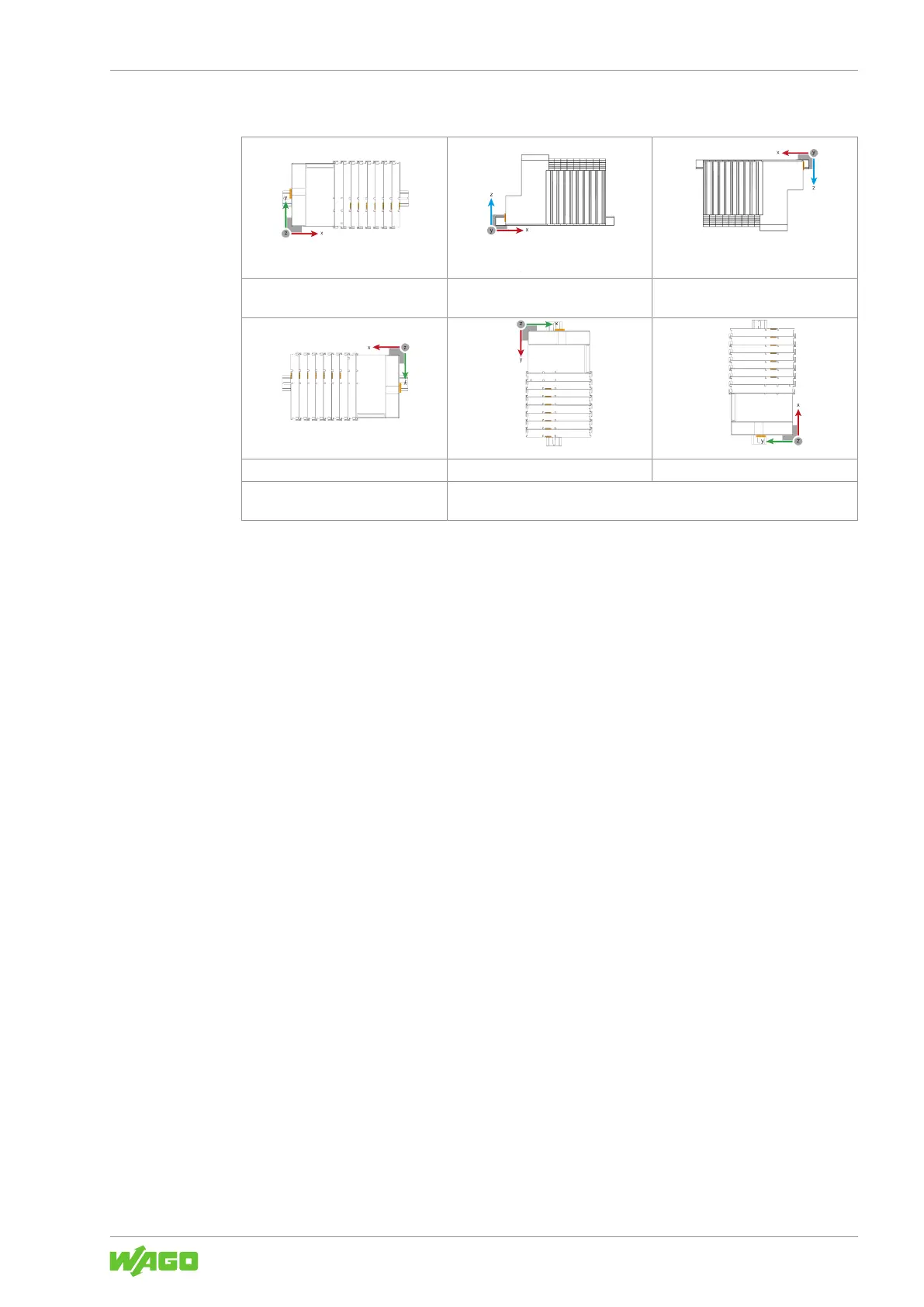

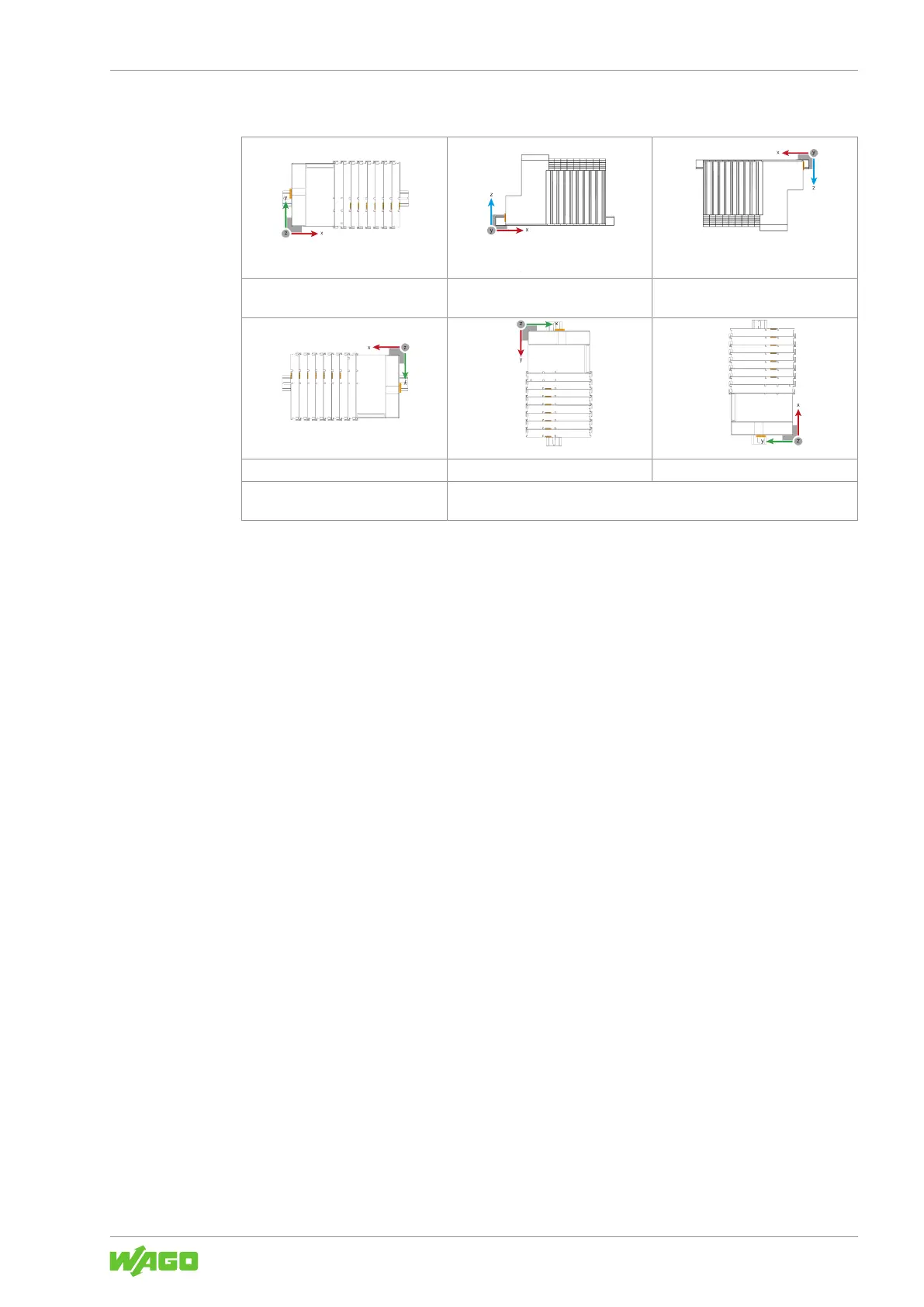

Overview of Mounting Positions

Nominal mounting position (horizon-

tal left)

Floor mounting position Ceiling mounting position

Mounting position, horizontal right Mounting position, vertical top Mounting position, vertical bottom

For vertical installation, always mount an end stop below the node to pre-

vent it from slipping off.

4.2.6 DIN-Rail Characteristics

To ensure optimum system construction, all system components can be securely

snapped onto a DIN-rail (35mm). Observe:

• The material must have high corrosion resistance.

• The DIN-rail geometry must not be altered.

• Prevent bending and twisting (torsion) e.g., by using sufficient attachment points.

• Use countersink-head screws, blind rivets, etc., to countersink the attachment points

beneath the node structure.

• The component DIN-rail contact (CuSn6) must not form a galvanic element with the

DIN-rail that is capable of generating a differential voltage of more than 0.5V (saline

solution of 0.3% at 20°C/68°F).

4.2.7 EMC Installations

• Ground the DIN-rail

Ground the DIN-rail to divert electromagnetic interference.

• Use shielded cables for data and signal lines

Use of shielded cables reduces electromagnetic interference and increases signal

quality. Measurement errors, data transmission faults and interference due to exces-

sive voltage can be prevented!

• Keep data and signal lines separate from interference sources

Route data and signal lines separately from all power supply cables and other sources

of high electromagnetic emissions (e.g., frequency converters or drives).

• Connect the cable shielding with the ground potential

Integrated shielding is mandatory to meet technical specifications regarding measure-

ment accuracy. Connect the cable shielding and ground potential at the inlet to the

cabinet or housing. This grounding allows induced interferences to dissipate and be

kept away from devices in the cabinet or housing.

Loading...

Loading...