Pre-start Checks

WP1624

Firewood Processor

34

6. Pre-start Checks

Efficient and safe operation of the Wallenstein wood processor

requires understanding operation and safety precautions

outlined in this section.

Follow the pre-operation checklist for personal safety and to

keep the machine in good mechanical condition.

Before operating the wood processor, check the following areas:

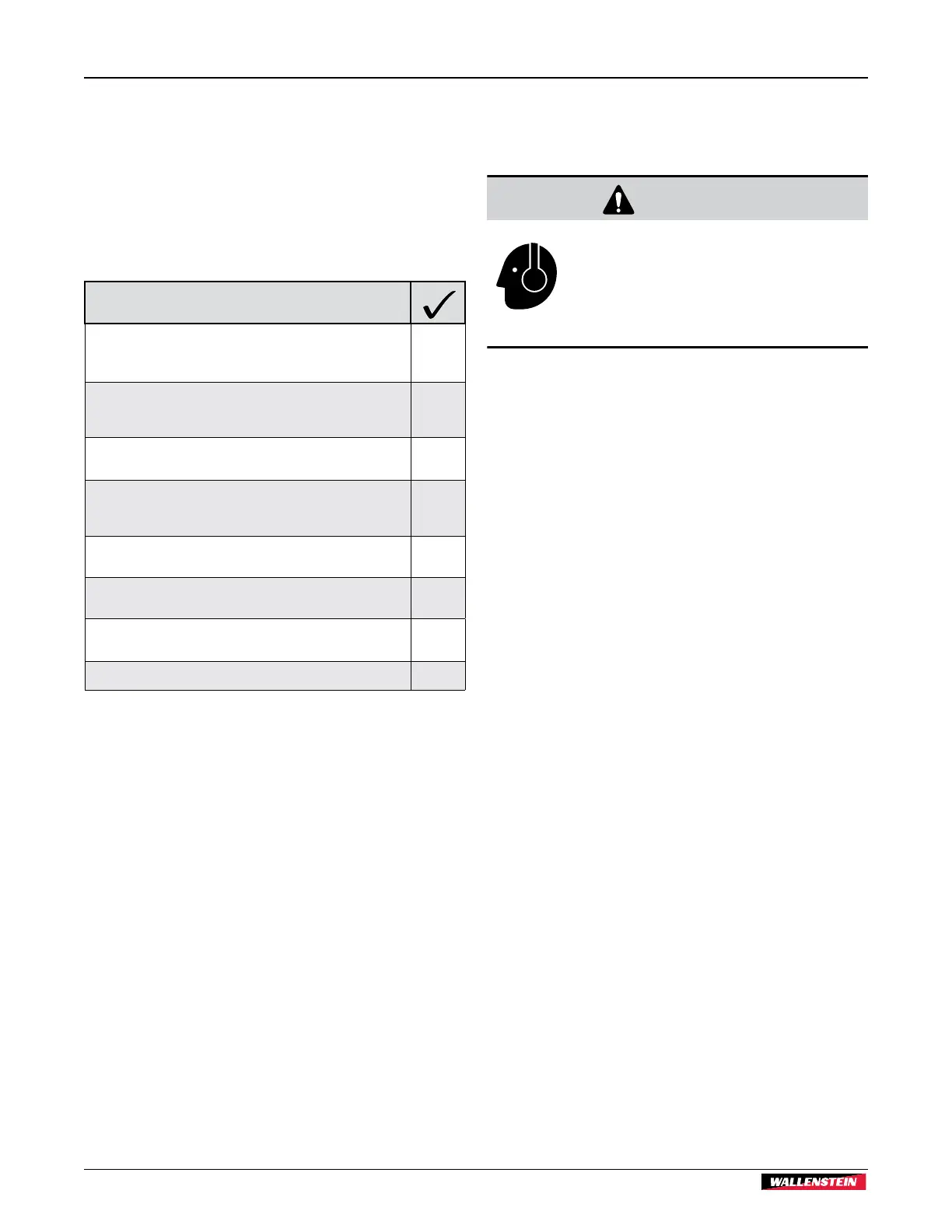

Area to check

Check and lubricate the machine per the schedule outlined

in the Maintenance Section. See page 53.

Check the splitting wedge and block. Inspect for damaged

or broken components and excessive wear. Lubricate,

repair or replace as required.

Check the saw chain. Look for broken or worn parts.

Check the bar guide and chain tightness.

Inspect the conveyor, infeed conveyor and live deck

chains. Tighten chains if necessary. Look for broken or

worn parts

Check and ensure that all covers, guards and shields are in

place, secured and functioning as designed.

Check and tighten all fasteners. Make sure equipment is

working and in good repair.

Check for hydraulic leaks. Tighten fittings or replace

components to stop leaks.

Make sure there is bar oil in the reservoir.

6.1 Before Starting the Engine

CAUTION!

Hearing loss hazard. Prolonged

exposure to loud noise may cause

permanent hearing loss. Use suitable

protection while operating the

machine.

W016

The operator has the responsibility of being familiar with and

following all operating and safety procedures.

Although this machine is easy to use, each operator should

review this section to get familiar with the detailed safety and

operating procedures.

1. Make sure the machine is set up correctly. See Machine

Set-up page 26.

2. Check the engine oil level. See page 35.

3. Check the hydraulic oil level. See page 52.

4. Check the fuel level. See page 35.

5. Check the bar oil level. See page 36

6. Review the Safety Rules on page 8. Make sure

each operator is trained and familiar with the set up and

operation of the machine. Review the Controls (see page

23).

7. Clear the area of bystanders.

Loading...

Loading...