WP1624

Firewood Processor

Pre-start Checks

35

6.2 Fuel Level Check

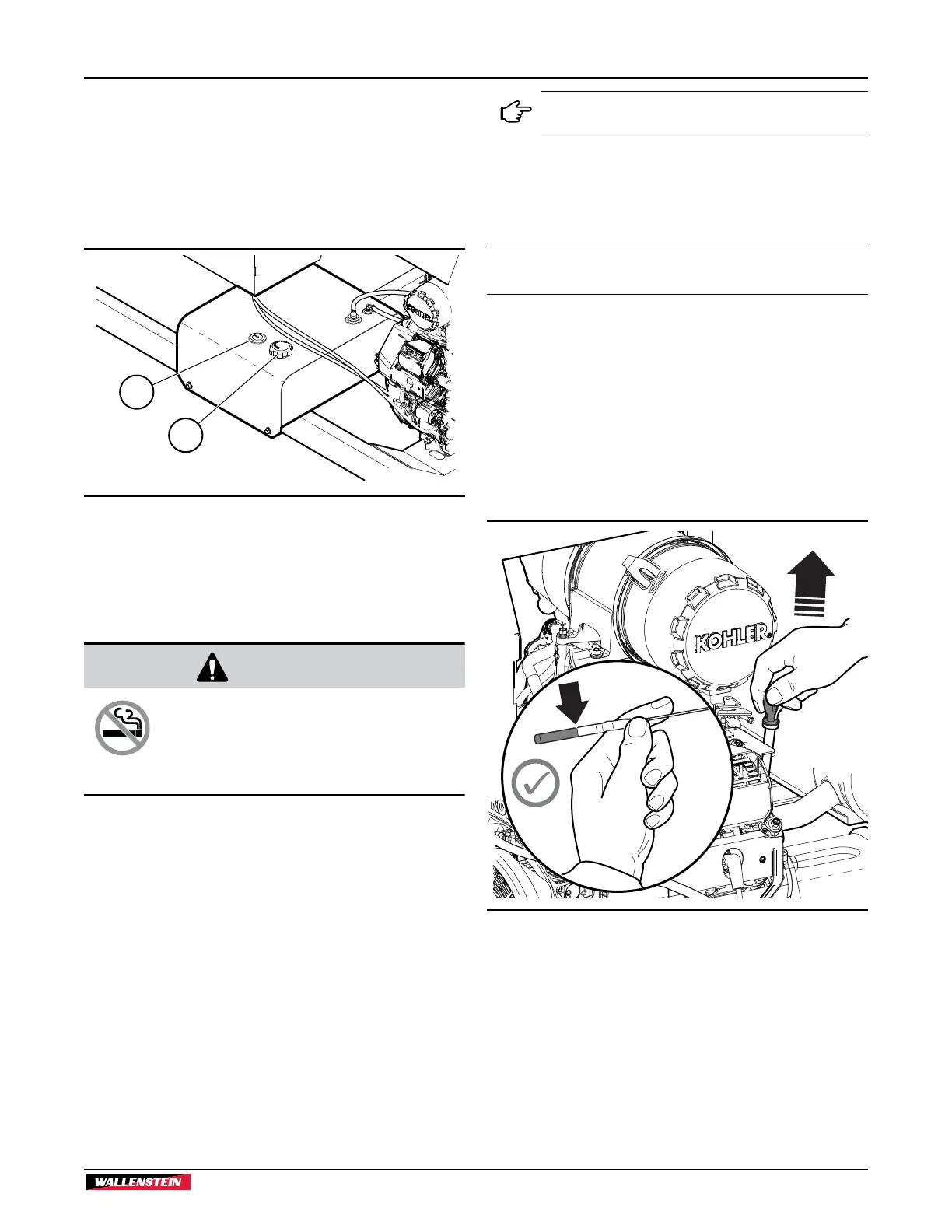

Check the fuel level daily. A gauge on the top of the tank

indicates fuel level. The fuel tank is located on the left-hand side

of the machine below the tool box. Avoid running the tank dry.

Starting with a full tank helps to eliminate or reduce operating

interruptions for refueling.

1

2

Fig. 38 – Fuel Tank

1. Fuel Level Gauge

2. Fuel tank Cap

6.2.1 Refueling

Fuel tank capacity: 10 US gal (37 L).

WARNING!

Fuel vapors can explode causing

injury or death. Do not smoke while

refueling. Keep sparks, fl ames, and hot

components away.

W027

Refuel in a well-ventilated area with the engine stopped. If the

engine has been running, allow it to cool first. Never refuel the

engine inside a building where gasoline fumes can come in

contact with flames or sparks.

For fuel specification, see Engine Fuel on page 52. Refer to

the engine manual for additional information on fuels.

Procedure:

1. Clean the area around fuel tank cap. Fill the tank to 1/2"

(12 mm) below bottom of filler neck to provide space for

any fuel expansion. Do not overfill.

2. Install fuel fill cap securely and wipe up any spilled fuel.

To help prevent running low on bar oil, top up

reservoir every time fuel is added.

6.3 Engine Oil Level Check

Check engine oil level daily. Check with the engine stopped.

IMPORTANT! Running the engine with a low oil level can

cause engine damage that is not covered by warranty.

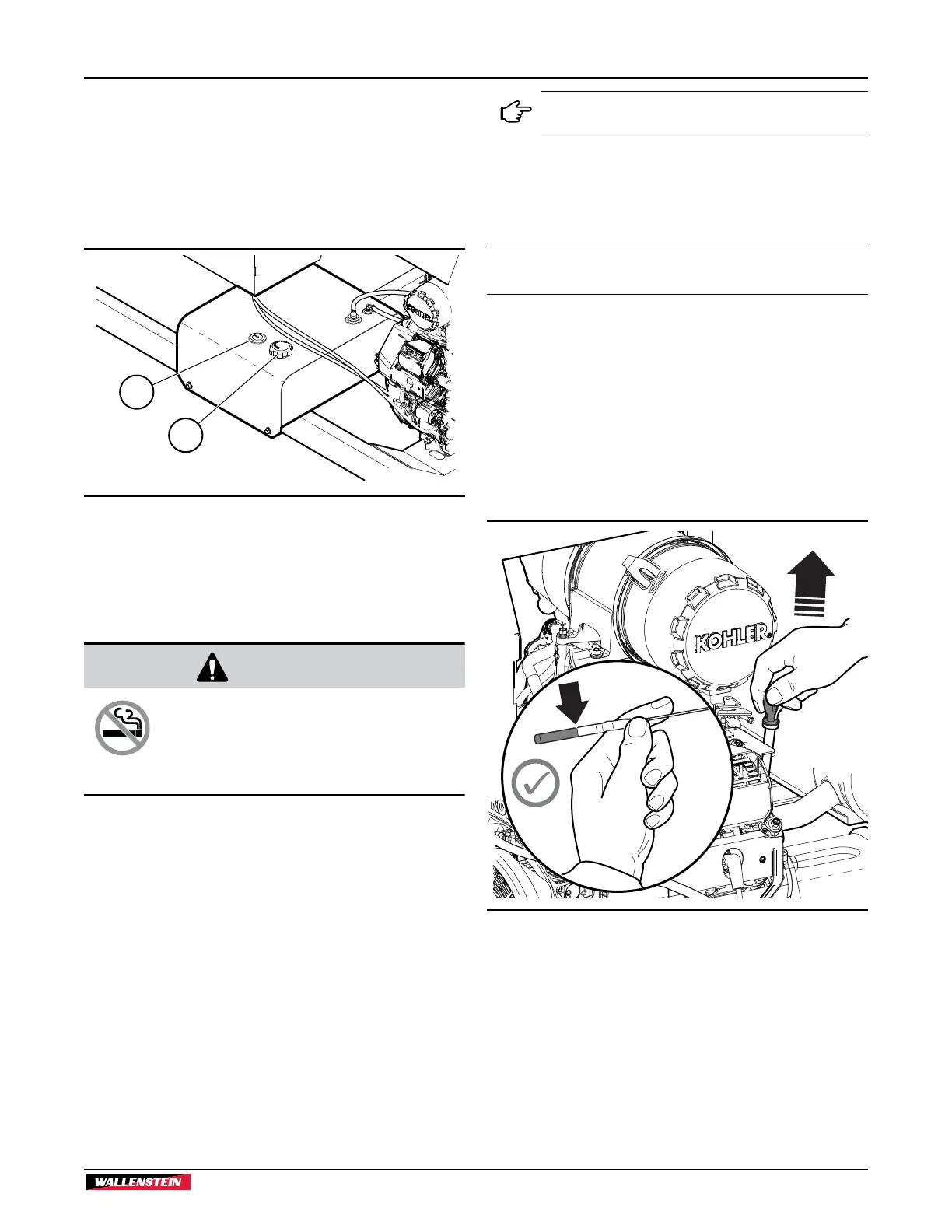

Procedure:

1. Remove the oil level dipstick and wipe it clean.

2. Fully insert the oil level dipstick, then remove it to check the

oil level.

3. If the oil level is low, remove the oil filler cap and add oil

until the level is at the FULL mark on the oil level dipstick.

SAE 10W-30 is recommended for general use.

4. Reinstall the oil level dipstick and oil filler cap.

00327

Fig. 39 – Checking Engine Oil Level

1. Oil Filler Cap

2. Oil Level Dipstick

Refer to the engine owner's manual included in the manual

tube for further information on engine oils.

Loading...

Loading...