Service and Maintenance

WP1624

Firewood Processor

58

8.8 Axles and Suspension

Except for periodic inspection of the fasteners used to attach the

axle to the frame, no other suspension maintenance is required.

For further information on maintenance and inspection

procedures regarding brakes, hubs, bearings and seals, refer to

the Dexter® axle service manual at www.dexteraxle.com.

The Dexter Torflex® axle suspension system is a torsion arm

type suspension completely self-contained within an axle tube.

The Torflex axle provides suspension through a steel torsion bar

surrounded by four rubber cords, encased in the main structural

member of the axle beam.

The wheel/hub spindle is attached to the torsion arm, fastened

to the rubber encased bar. As load is applied, the bar rotates

causing a rolling / compressive resistance in the rubber cords.

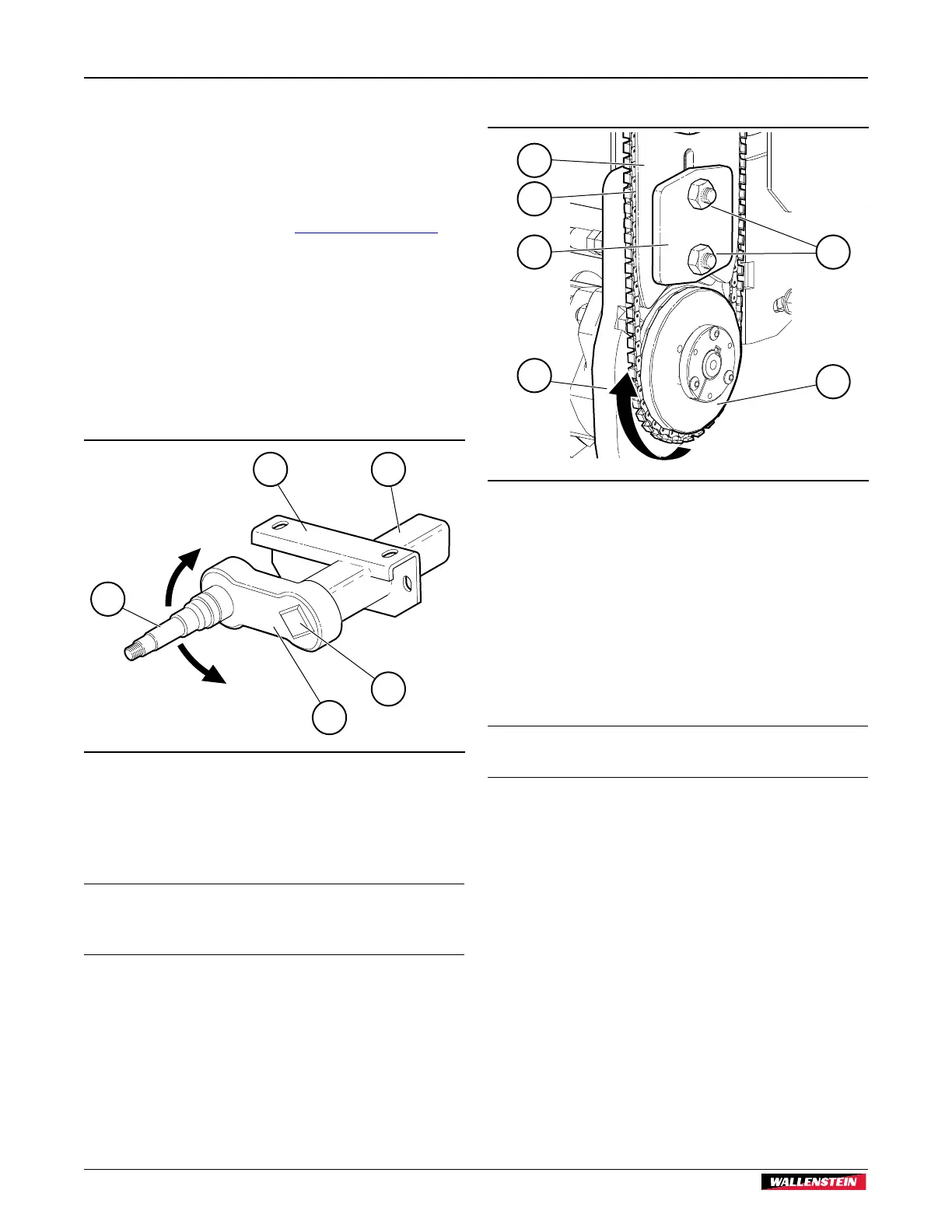

00356

1 2

3

4

5

Fig. 89 – Axle

1. Spindle

2. Mounting Bracket

3. Axle Tube

4. Torsion Bar

5. Torsion Arm

IMPORTANT! Do not weld on the axle beam. Heat

generated from welding could damage the rubber

suspension cords.

8.9 Saw Chain Maintenance

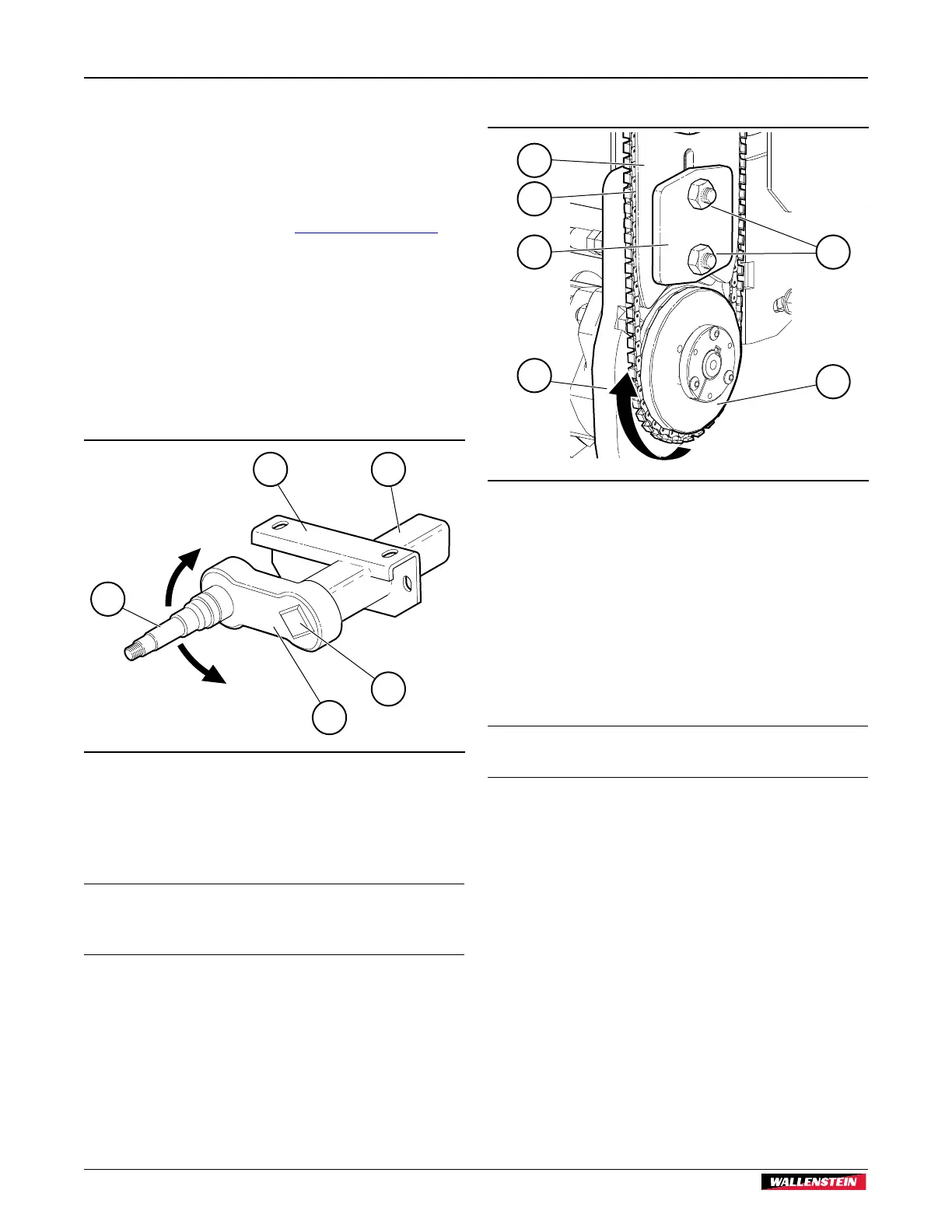

00412

6

5

4

3

1

2

Fig. 90 – Saw Parts

1. Bar Nuts

2. Drive Sprocket

3. Direction of Chain Travel

4. Clamp plate

5. Cutting Chain

6. Guide Bar

8.9.1 Sharpening

Use chain and bar in sets to equalize wear. Keep chain sharp to

make faster cuts and reduce energy required to make the cuts.

IMPORTANT! Refer to the Oregon® Mechanical Timber

Handbook for instructions on sharpening the saw chain.

• Before sharpening, clean the saw chain to remove dirt,

debris and bar oil so it can be inspected thoroughly.

• Inspect for broken, cracked, damaged or missing chain

parts.

• Look for signs of excessive chain stretch. Stretch indicates

wear occurring to the flange of the rivet and holes in the

drive links.

• Inspect the chain chassis for abnormal wear patterns,

which are indicators of issues with the guide bar and drive

socket.

• Discard the chain if it has broken, parts are missing, there

is excessive stretch, or it has loose rivets.

Loading...

Loading...