WP1624

Firewood Processor

Service and Maintenance

63

8.15 Electrical System – General

IMPORTANT! When assembling or replacing wire

harnesses, apply a thin coating of silicone dielectric grease

to the harness connectors.

Clean off any corrosion or loose particles, then apply a

small amount to the surfaces of the connectors where they

meet. The grease helps to stop any possibility of future

corrosion.

Reassemble the connection. If grease squeezes out, wipe

off.

8.16 Welding

IMPORTANT! If welding on the machine becomes

necessary, sensitive electronic components must be

removed from the machine beforehand. Welding can

produce stray voltage spikes that can damage these items.

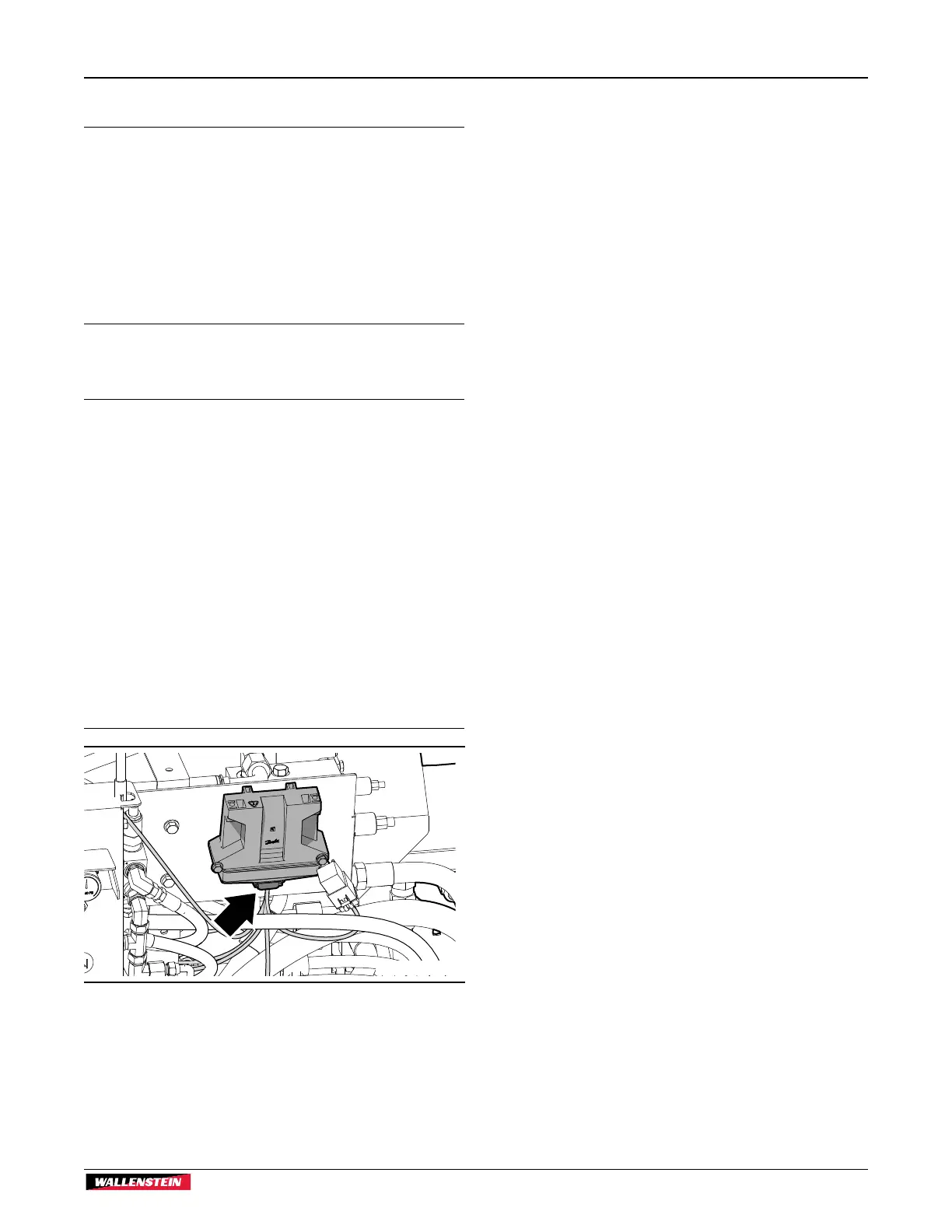

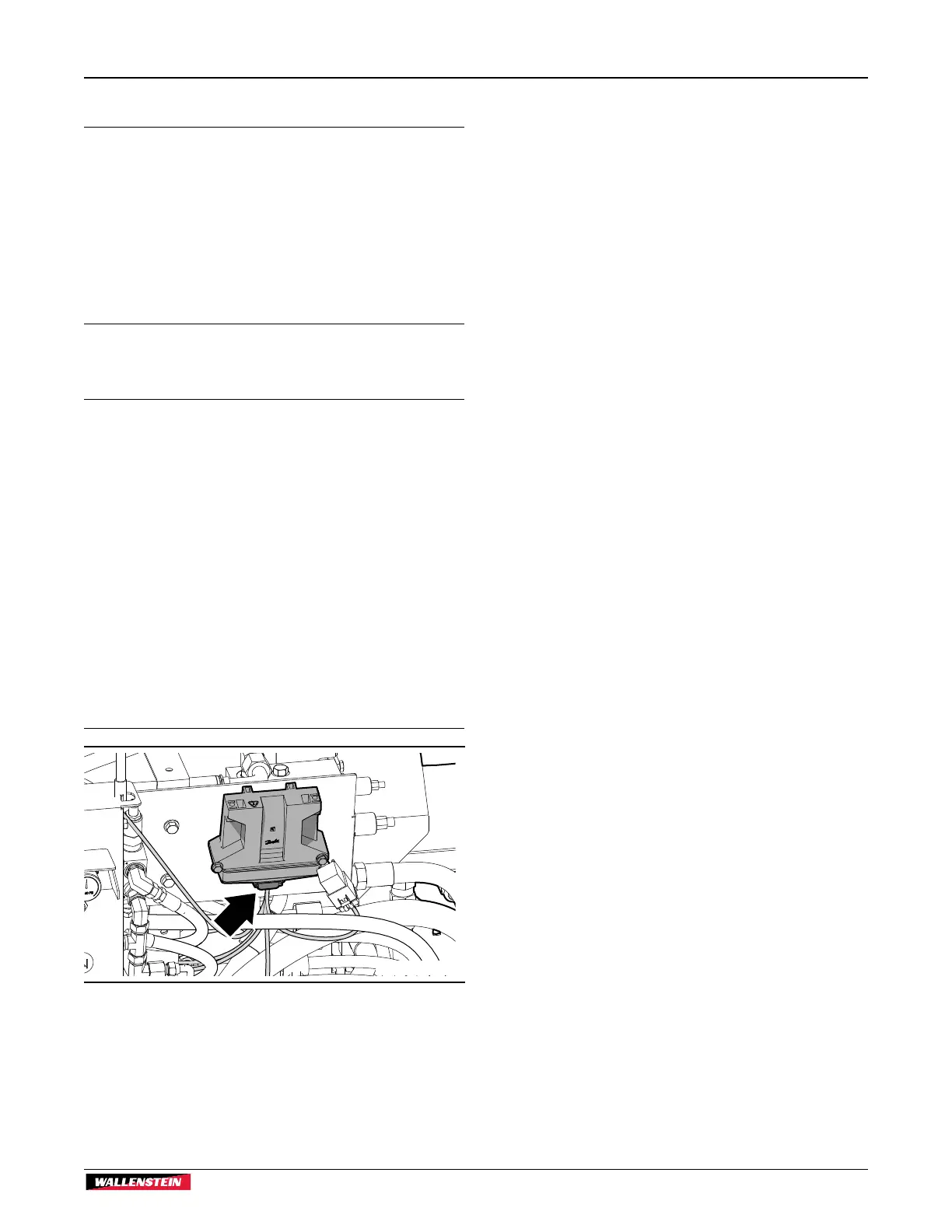

• Disconnect and remove the P3 Controller from the

machine. Remove the cover over the hydraulic tank to

access it.

• Disconnect/unhook the machine from the tow unit,

tractor, or carrier machine.

• Disconnect the machine’s battery. Disconnect the

negative battery cable first before disconnecting the

positive battery cable.

• Place the welder ground clamp as close to the work

area as possible. Keep the welder cables away from the

control system electrical harnesses.

Fig. 100 – P3 Controller

8.16.1 Welding Safety

• If welding repairs are required, have them performed by

a trained welder with proper service instructions. Know

the material to be welded and select the correct welding

procedure and materials (electrodes, rods, wire) that

provide a weld metal strength equivalent to the parent

material.

• Work with extra care when welding, grinding or torch

cutting near flammable objects.

• Welding on painted surfaces releases dangerous fumes

and results in a poor weld joint that can result in failure and

potential accidents. Always remove paint from areas to be

welded.

• Heated paint gives of poisonous gases. Therefore, paint

must be removed from an area with a radius of at least

4" (10 cm) before carrying out welding, grinding or gas

cutting. In addition to the health hazard, the weld is of

inferior quality and strength if the paint is not removed.

Methods and precautionary measures when removing paint:

Blasting—use respiratory protective equipment and protective

goggles.

Paint remover or other chemicals—use a portable air extractor,

respiratory protective equipment and protective gloves.

Grinding—use a portable air extractor, respiratory protective

equipment and protective gloves and goggles.

Loading...

Loading...