WP1624

Firewood Processor

Pre-start Checks

37

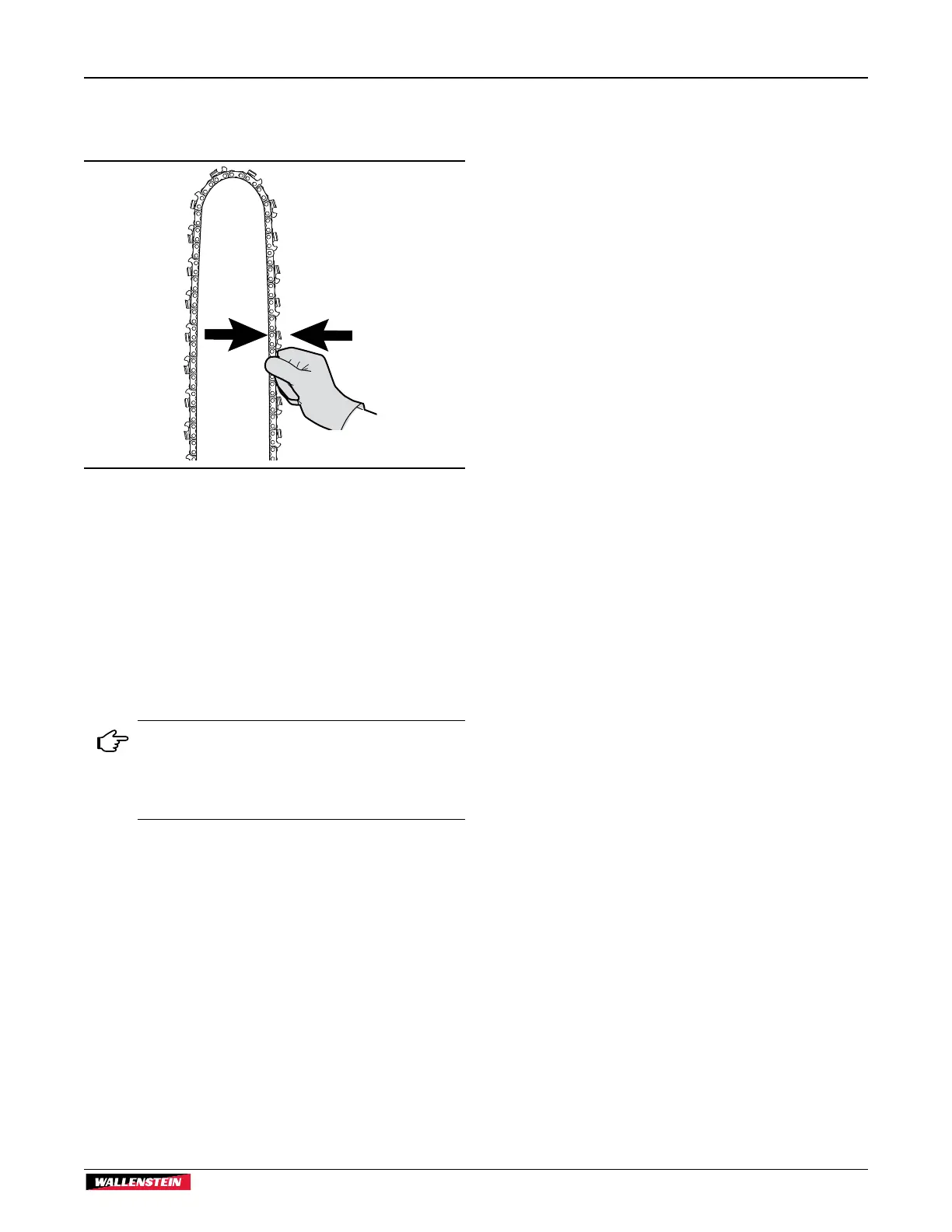

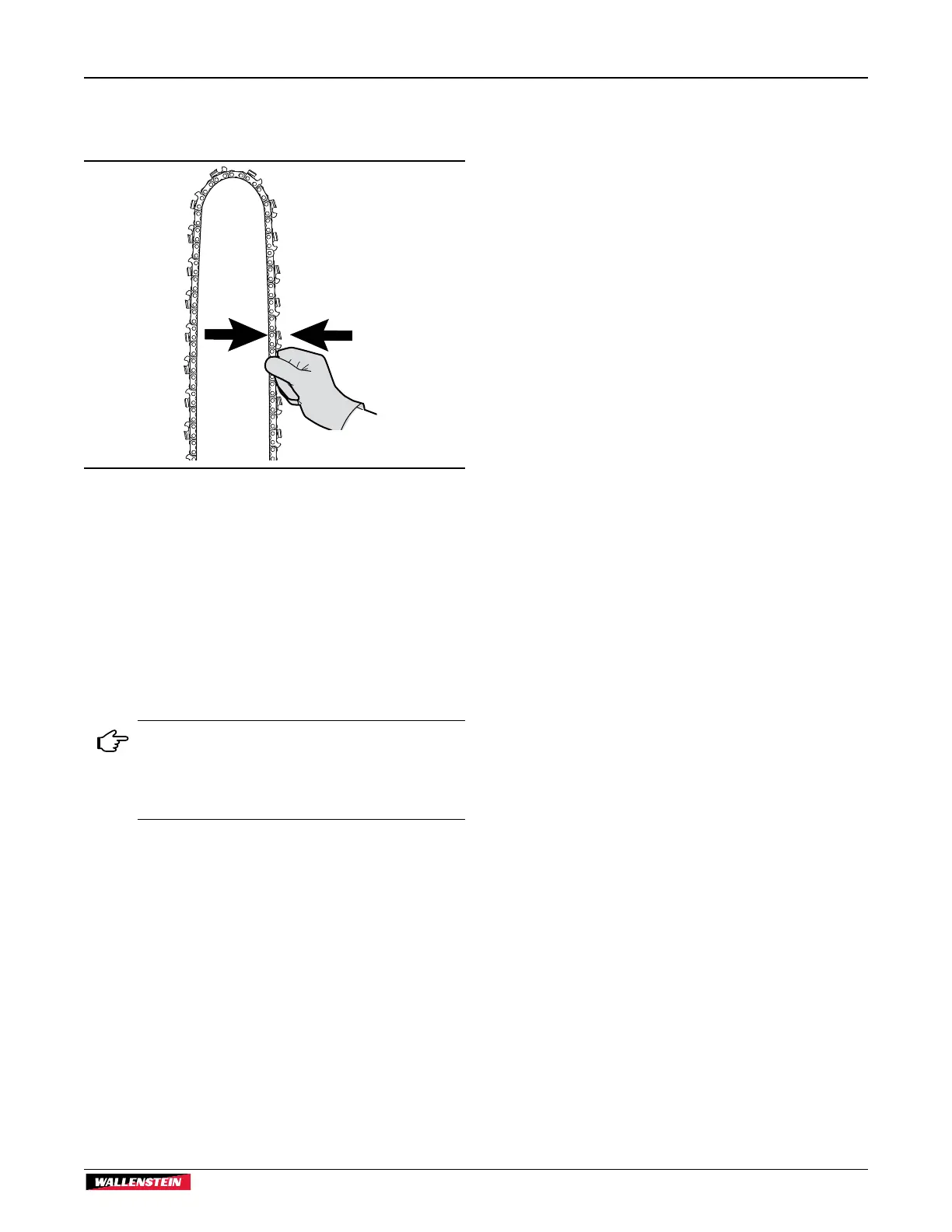

Grasp the chain at the mid point of the guide bar and pull the

saw chain away from the bar rails. The drive link tangs should

nearly come out of the bar groove.

Fig. 43 – Check Saw Chain Tension

• Inspect for broken, cracked, damaged, or missing saw

chain components. Inspect loose rivets. If rivet can be

turned by hand, it is too loose.

• Inspect for excessive stretch. Stretch is actually wear

occurring to the flange of the rivet and the holes in drive

links.

• Inspect the chain chassis for abnormal wear patterns,

which are indicators of other cutting system issues with the

guide bar and drive sprocket.

Refer to the Oregon® Mechanical Timber

Handbook for additional information on the saw

chain and bar. A copy of this manual can be

found on the Wallenstein website under Technical

Reference.

6.7 Machine Break-In

Although there are no operational restrictions on the wood

processor when used for the first time, it is recommended that

the following mechanical items be checked:

For new saw chain, check tension often during the first 10

minutes of use.

Consider transporting new and newly sharpened saw chain to

and from the job site in a container with lubricant.

1. Lubricate your saw chain prior to use.

2. Increase saw speed gradually over the first 2–4 minutes

of running time while cycling the guide bar, until bar oil is

observed coming off the tip.

3. Check saw chain tension. Adjust if necessary.

After 1–5 hours of operation:

4. Check all nuts, bolts and other fasteners. Tighten to their

specified torque.

5. Check hydraulic system for leaks. Tighten all leaking fittings

and replace any leaking components.

6. Check machine fluid levels: Fuel, engine oil, and hydraulic

oil reservoir. Top up as required.

7. Check for entangled material. Remove all entangled material

before resuming work.

After 20 hours of operation:

8. Repeat Steps 4 through 7 listed above.

9. Check and adjust the tension on all drive chains. Chains

may stretch slightly as they wear in. See page 61.

10. Go to the normal servicing and maintenance schedule as

defined in the Maintenance Section. See page 52.

After 50 hours of operation:

• Re-tension Infeed Conveyor chain. See page 60

• Re-tension the Live Deck chain. See page 60.

• Re-tension the Integrated Conveyor chain (as equipped).

See page 62.

Loading...

Loading...