Service and Maintenance

WP1624

Firewood Processor

54

8.4 Hydraulic Oil – Changing

CAUTION!

Risk of burns to exposed skin.

Hydraulic oil becomes hot during

operation. Hoses, lines, and other

parts become hot as well. Wait for

the oil and components to cool

before starting any maintenance or

inspection work.

W028

Change the hydraulic oil in the reservoir at 100 hours of

operation or annually.

IMPORTANT! Clean the suction strainers and return filter in

the tank at the same time.

• Hydraulic oil type: Dexron III ATF.

• Hydraulic oil tank capacity: 26 US gal (102 L)

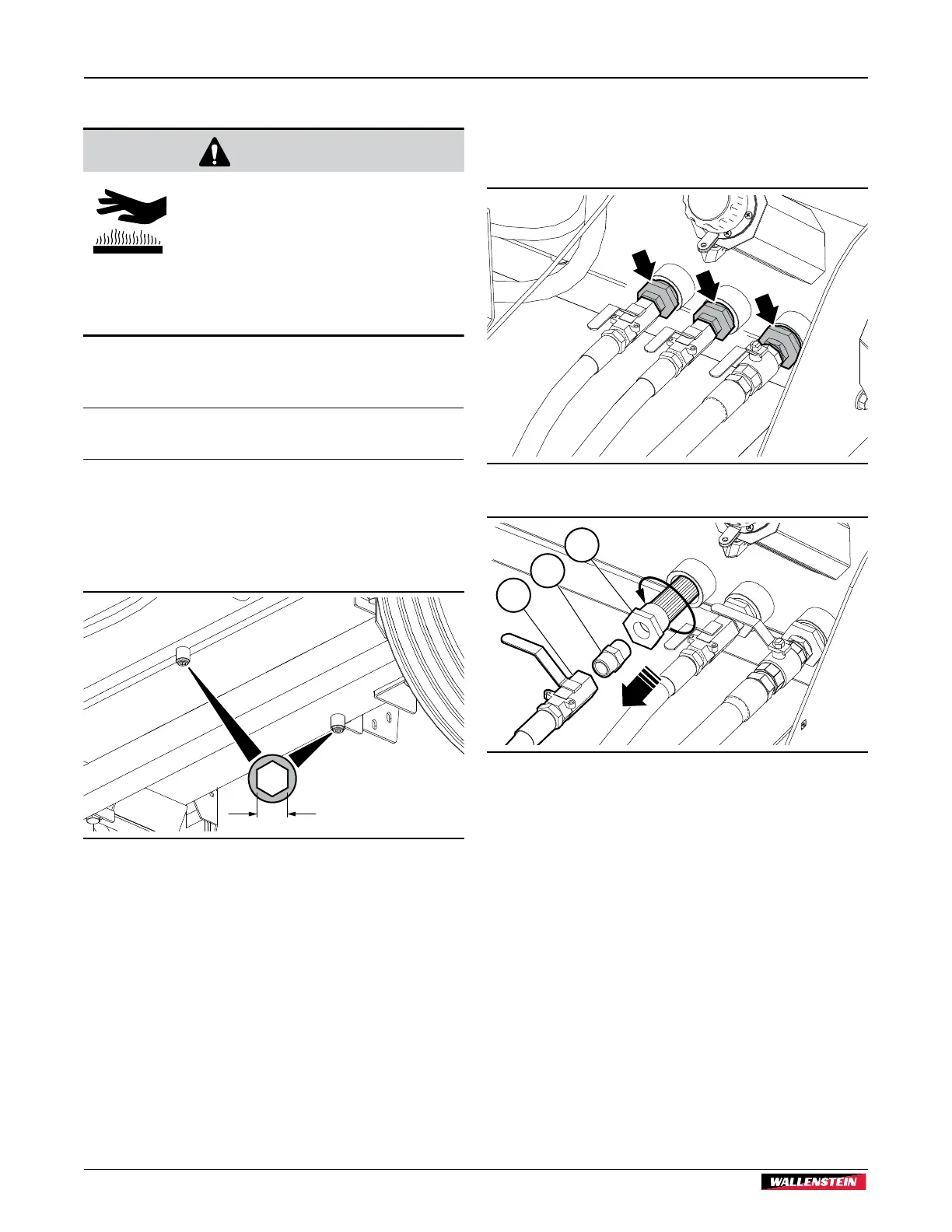

The hydraulic tank drain plug is located under the machine. A

3/8" Allen wrench is required to remove it.

01058

3/8"

Fig. 80 – Hydraulic Tank Drain Plug

Procedure

1. Have a drain pan ready of suitable capacity.

2. Clean the area around drain and remove the drain plug.

3. Allow the oil to fully drain, then flush the tank. Dispose of

used oil in a environmentally acceptable fashion.

4. Install the drain plug.

5. Clean the suction strainer filters before filling the tank.

8.4.1 Suction Strainers, Cleaning

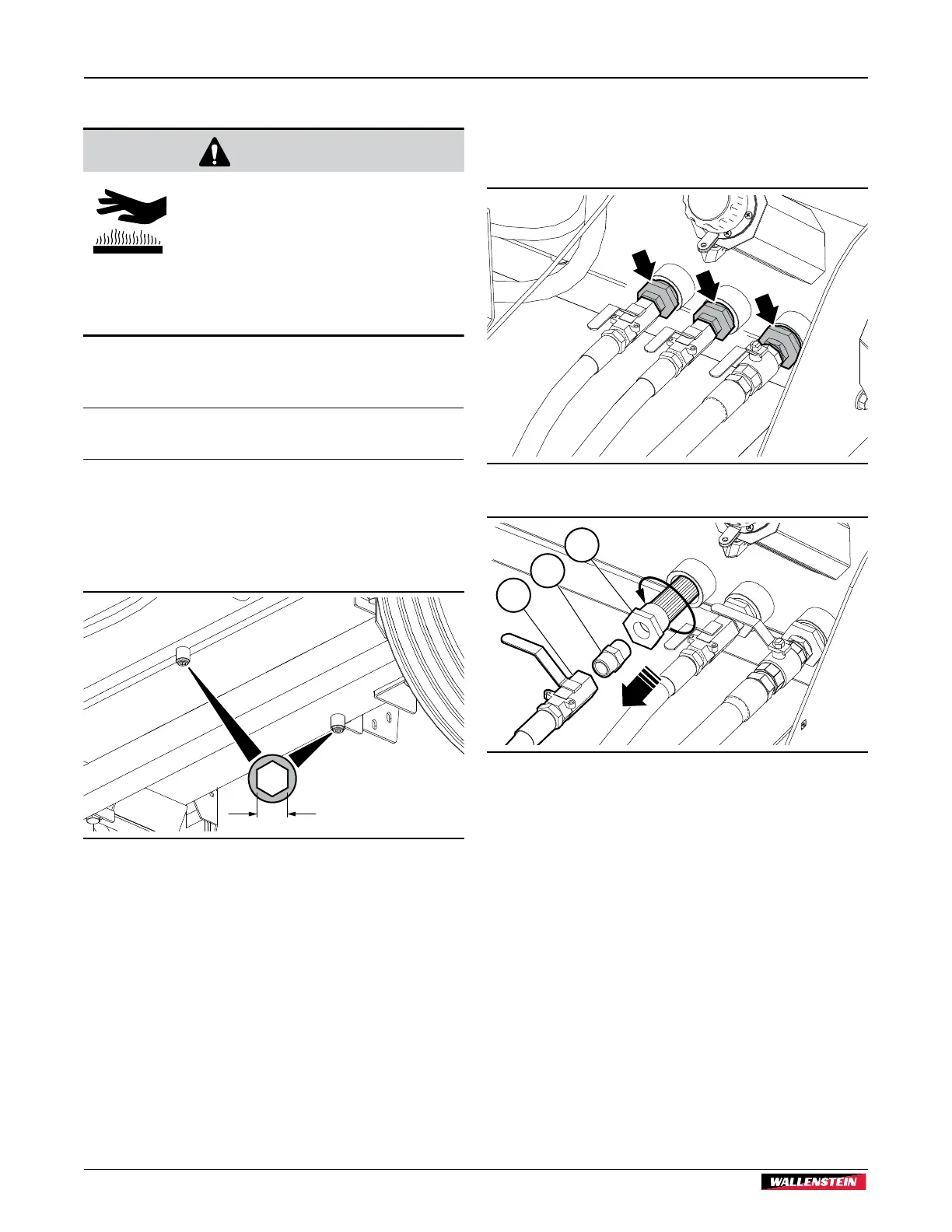

The three suction strainers are made of stainless steel screen

and are reused. The strainers are located on the bottom of the

tank at the pump suction line connections.

01056

Fig. 81 – Suction Strainers

01057

1

2

3

Fig. 82 – Suction Strainer Removal

1. Suction Strainer

2. Nipple

3. Shut-off Valve

1. Remove the hose and shut-off valve.

2. Remove the suction strainer and place it in a solvent tank.

Use a small brush to clean it. Examine the strainer screen

and replace it if there are holes or damage.

3. Dry the suction screen thoroughly, then re-install the

strainer, valve and suction hose.

Loading...

Loading...