Troubleshooting Guide

WP1624

Firewood Processor

64

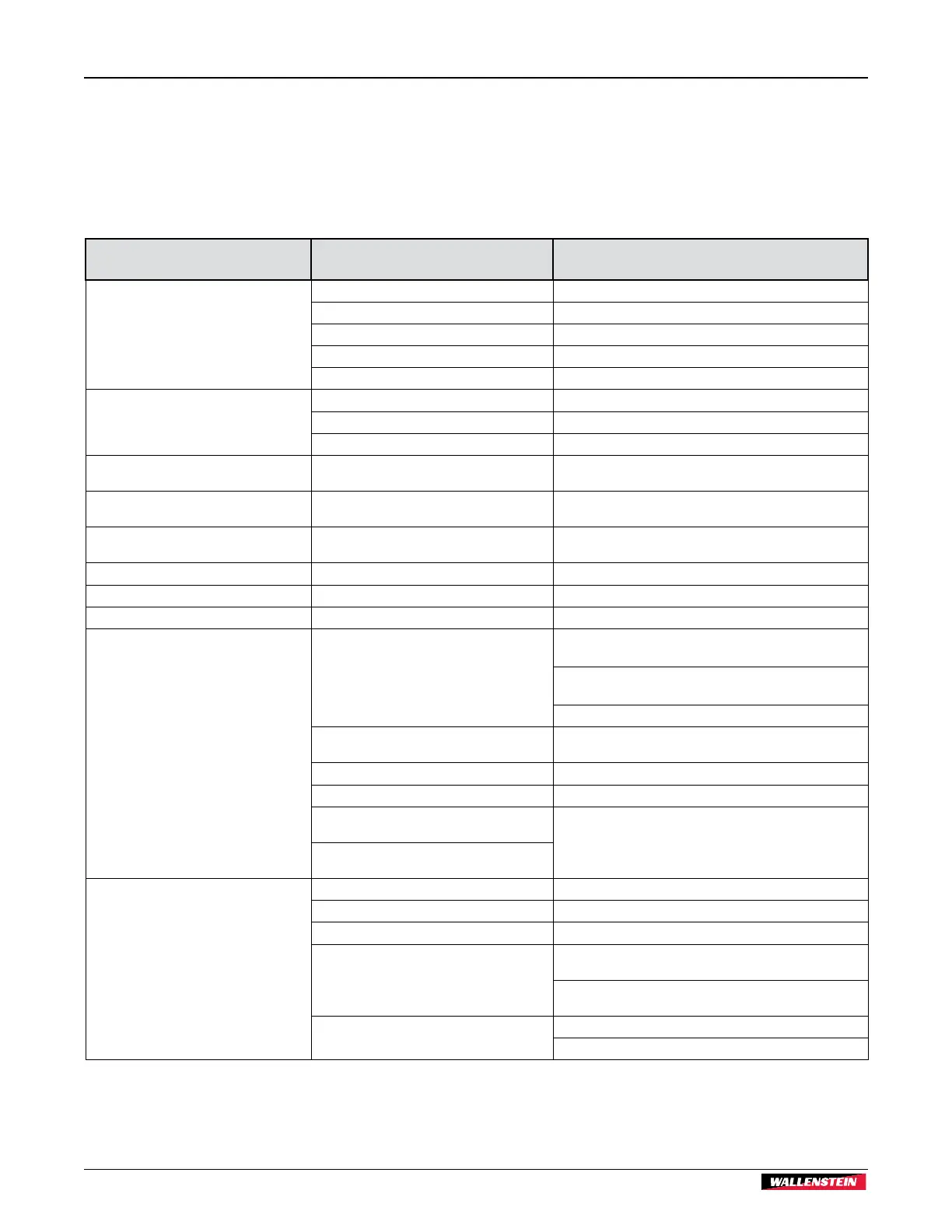

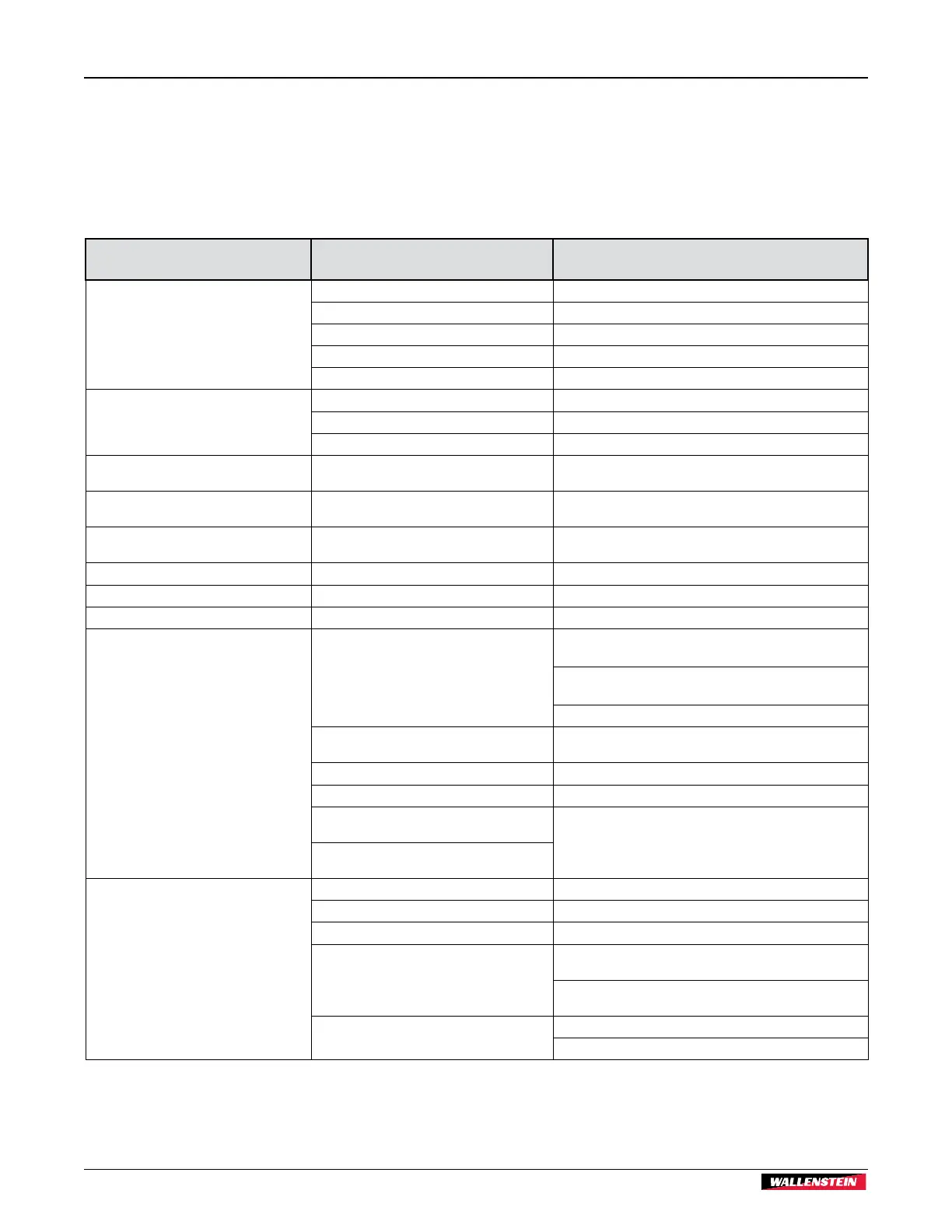

9. Troubleshooting Guide

The Wallenstein Trailer wood processor is a simple and reliable

system that requires minimal maintenance.

The following table lists problems that may be encountered,

possible causes and solutions.

If a problem remains unsolved after reading through this section,

contact the local dealer, distributor or Wallenstein Equipment

Inc. Before calling, have the serial number for the wood

processor handy.

Problem Cause Solution

Splitter cylinder rod moves slowly or does

not move.

Wood jammed around wedge. Shut machine off and safely remove wood.

Low hydraulic oil pressure. Oil filter plugged. Change filter.

Low hydraulic oil pressure. Low hydraulic oil level. Add oil.

Not enough pressure. Call technician. System relief setting may be low.

Low engine speed. Check that choke is off. Check throttle is set to maximum.

Control handle doesn't go to neutral after

splitter rod is fully retracted.

Detent set too tight. Call technician. Adjustment required to detent on valve.

Hydraulic fluid too cold. Allow machine to warm up.

Hydraulic fluid is contaminated. Change hydraulic oil and filter.

Control handle goes to neutral before splitter

rod is fully retracted.

Detent set too loose. Call technician. Adjustment required to detent on valve.

Control handle doesn't go to neutral when

released.

Valve may be damaged. Valve may need to be serviced or replaced. Call technician.

Cylinder stops on contact with wood. Hi-low valve not functioning.

Hi-low valve may need to be serviced or replaced. Call

technician.

Wedge jumps. Wood jammed sideways or at an angle. Clear jammed wood.

Leaking hydraulic hose. Hose worn or damaged. Replace hose.

Leaking cylinder. Seals worn. Call technician. Seal replacement may be required.

Infeed conveyor or live deck does not

operate.

Low hydraulic oil pressure.

Oil filter plugged. Change filter.

Low hydraulic oil level. Add oil.

Pump may need to be serviced or replaced. Call technician.

Wood debris caught between the scrapers and

conveyor trough.

Clear out debris.

Scrapers frozen in the conveyor trough. Free the infeed chain from the trough.

Chain skipping, too loose Tighten chain.

Log is crooked or untrimmed branches are

catching on the infeed conveyor.

Rotate log with peavy or trim branches off.

Hydraulic conveyor is jammed resulting in no oil

flow available.

Saw overheating; harder to cut.

Saw chain is dull. Sharpen or replace chain.

Bar oil is low Add oil.

Chain tension too loose. Adjust chain tension.

Bar oiler not working.

Move oil reservoir to gravity feed mounting position on chain

saw guard.

No power to pump as a result of pump failure, or pressure

switch failure, harness issue. Call technician.

Saw is cutting at an angle due wear on bar.

Flip bar or replace.

Have bar surfaces reground.

Loading...

Loading...