Pre-start Checks

WP1624

Firewood Processor

36

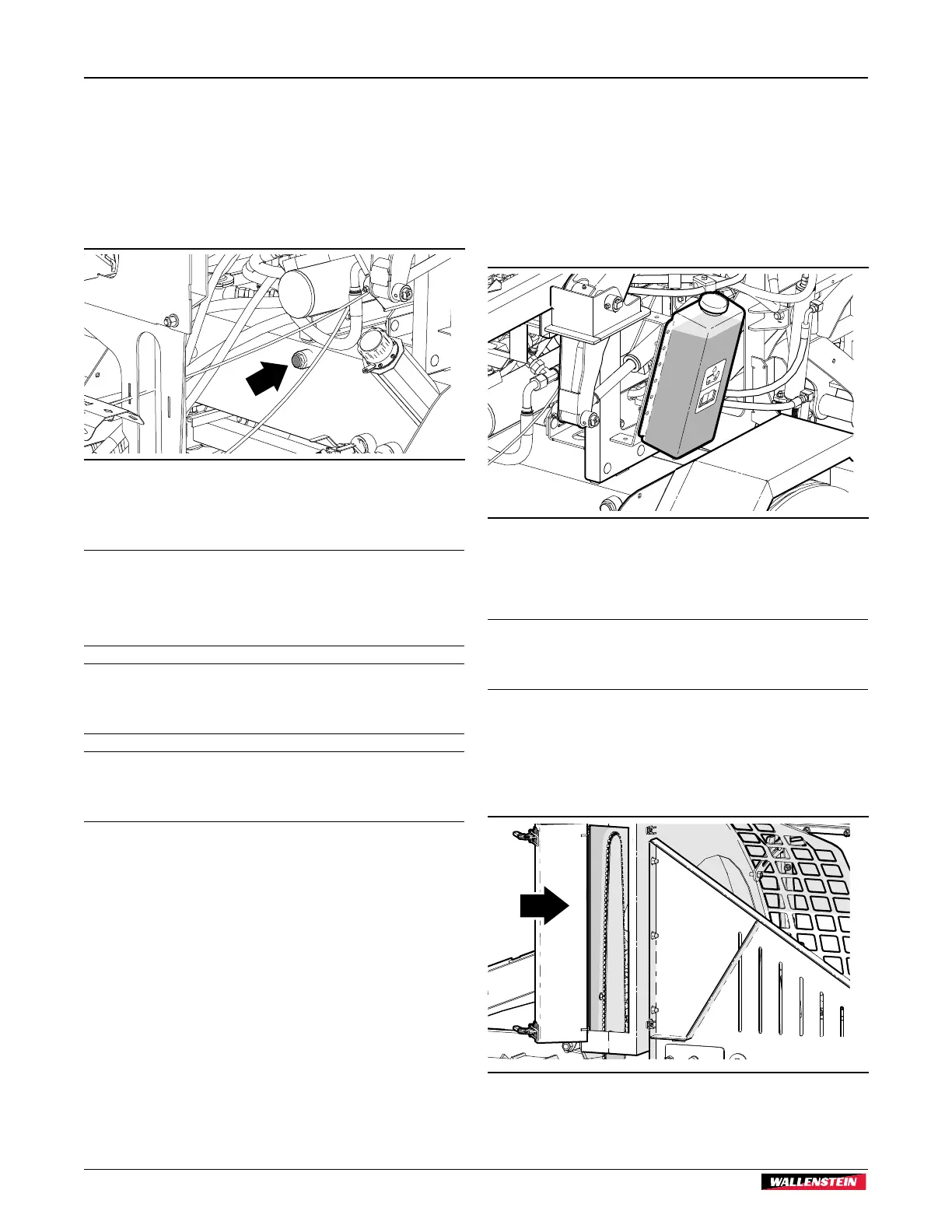

6.4 Hydraulic Oil Level Check

Check hydraulic oil level daily. The hydraulic oil tank sight

glass is on the front of the tank. Check level with the engine

stopped.

The proper level is when the oil fills the glass window. If the

level is not visible in the sight glass, add oil.

Fig. 40 – Hydraulic Tank Oil Level Check

1. Hydraulic Tank Filler Cap

2. Oil Level Sight Glass

IMPORTANT! Do not operate machine if oil level is not

visible in the sight glass. Damage to the pump and other

components can occur.

Do not overfill the tank past the sight glass window.

IMPORTANT! Hydraulic oil quality should be inspected

every 50 hours. If the oil is dirty or smells burnt, it should be

replaced.

IMPORTANT! Be aware of high oil temperatures.

Temperatures higher than 180 °F (82 °C) could cause seal

damage and degrade oil quality.

6.4.1 Adding Oil to the Tank

The hydraulic system uses Dexron® III ATF.

Procedure:

1. Clean the area around filler cap and remove it.

2. Use a clean funnel and add oil until the level just fills the

sight glass window.

3. Install filler cap securely. Wipe up any spilled oil.

Check levels after changing filters or servicing hydraulic

components.

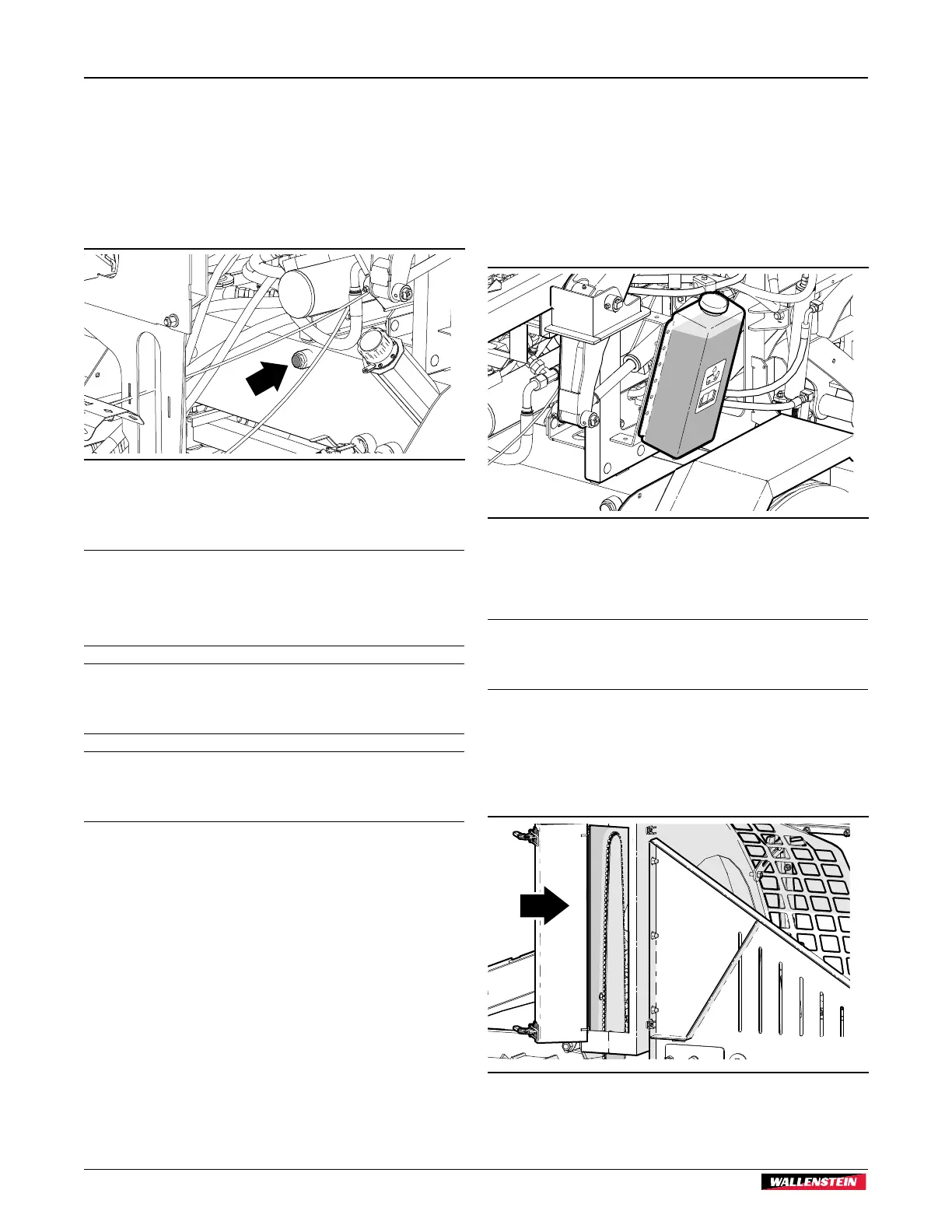

6.5 Chain Saw Bar Oil level

Check bar oil level regularly. The bar oil reservoir is located on

the left-hand side of the processor.

Your cutting system operates in a challenging environment and

depends on sufficient lubrication to minimize wear and extend

the life of operation. At start up, allow adequate time for the oil

from the reservoir to reach the cutting system.

Fig. 41 – Bar Oil Reservoir

Bar and chain oils provide adequate lubrication to the cutting

system when used correctly.

IMPORTANT! The cutting system must use chain saw bar

oil only. Hydraulic or engine oils do not provide adequate

lubrication. Non-approved lubricants can void saw warranty.

6.6 Saw Chain – Checking

Check saw chain tension regularly. To tension the saw chain,

see page 59.

00369

Fig. 42 – Saw Access Door

Loading...

Loading...