WP1624

Firewood Processor

Service and Maintenance

53

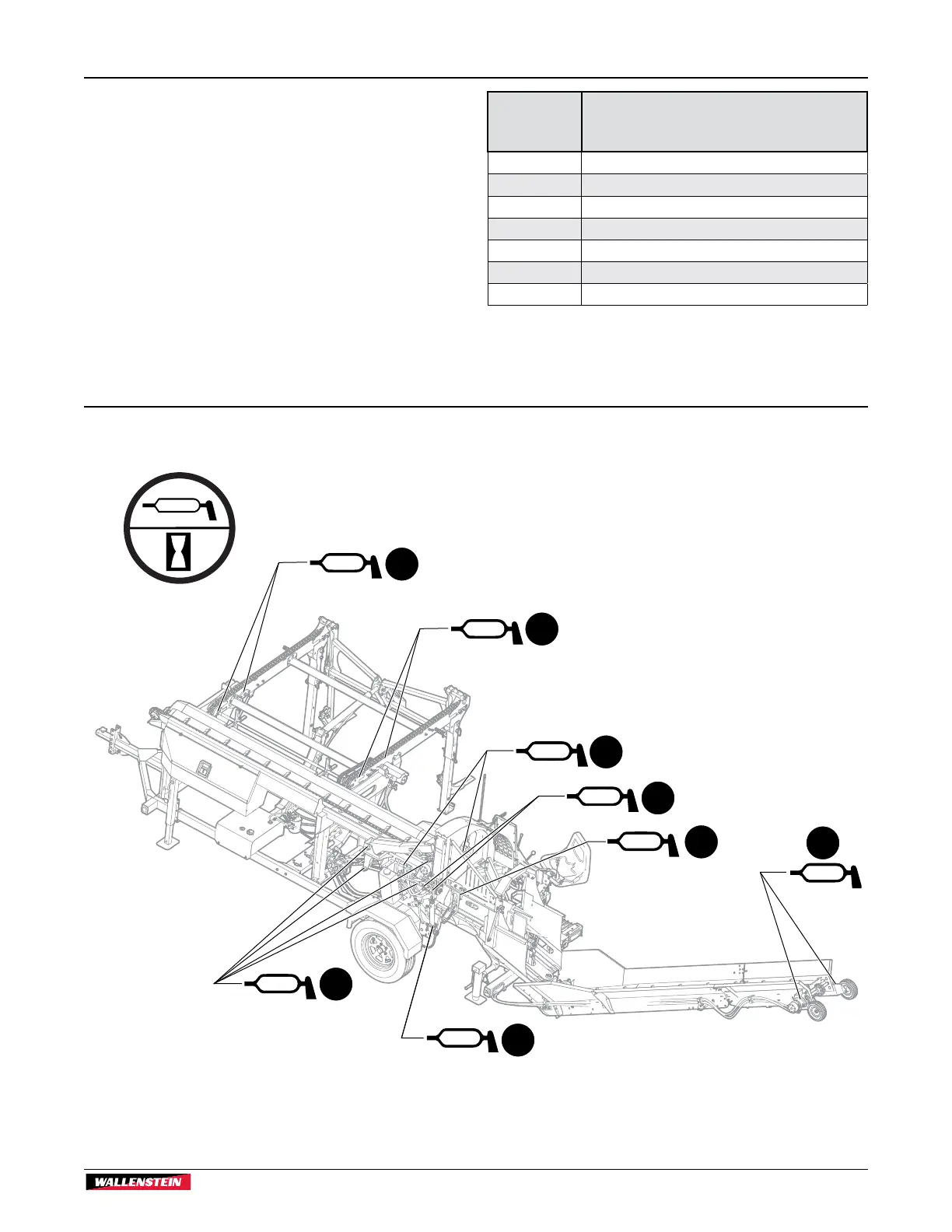

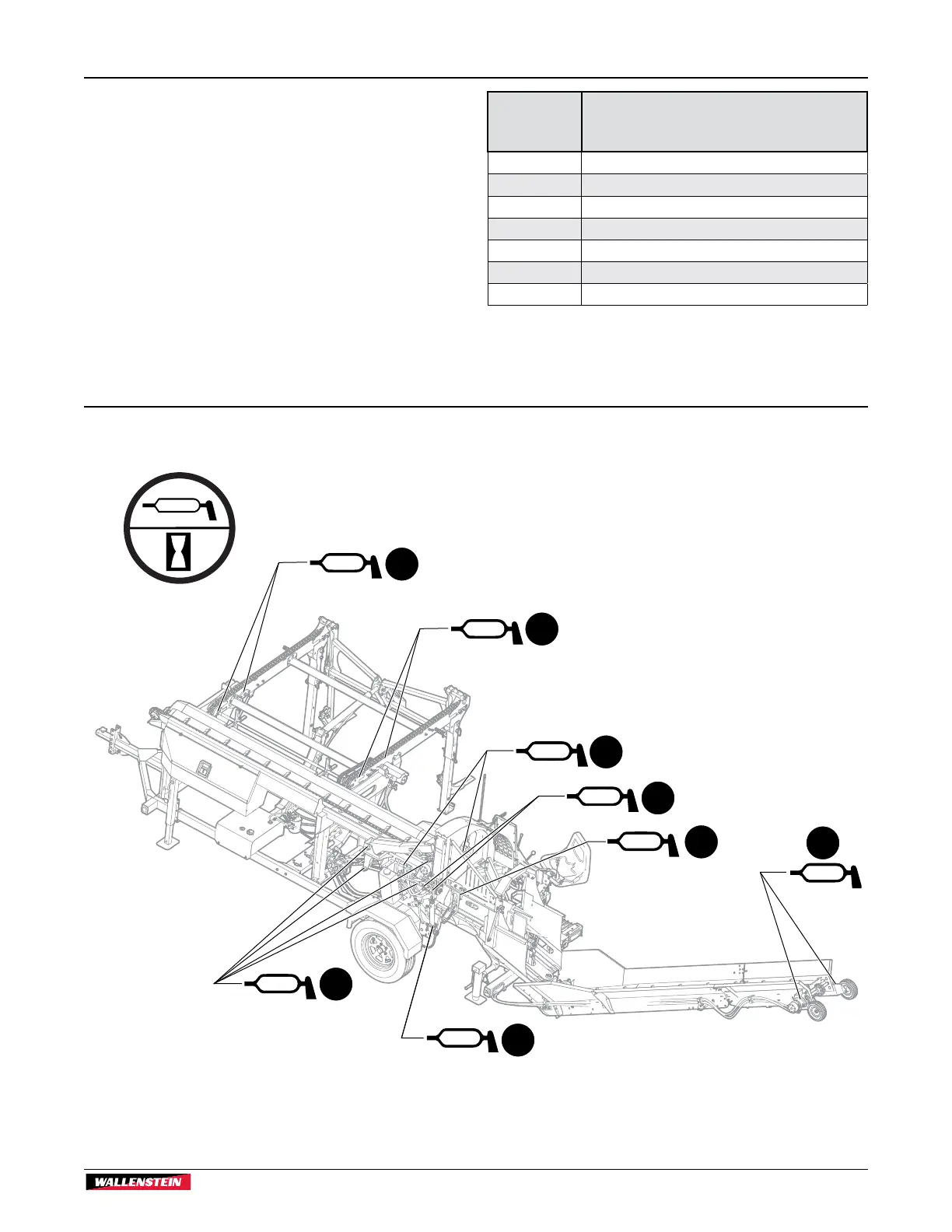

8.3 Greasing

• Use a hand-held grease gun for all greasing.

• Wipe grease fitting with a clean cloth before greasing to

avoid injecting dirt and grit.

• Replace and repair broken fittings immediately.

• If fittings will not take grease, remove and clean thoroughly.

Also clean lubricant passageway. Replace fittings if

necessary.

Location Grease Points

– Every 50 hours or annually

1 Live deck drive and tilt – 4 points

2 Infeed conveyor drive – 2 points

3 Log dropper – 1 point

4 Saw drive pivot – 2 points

5 Saw rotate cylinder – 1 point

6 Top Roller Clamp pivot – 4 points

7 Conveyor drive – 2 points

1

1

2

3

5

7

6

Fig. 79 – Grease Points

4

Loading...

Loading...