24 Installation

1

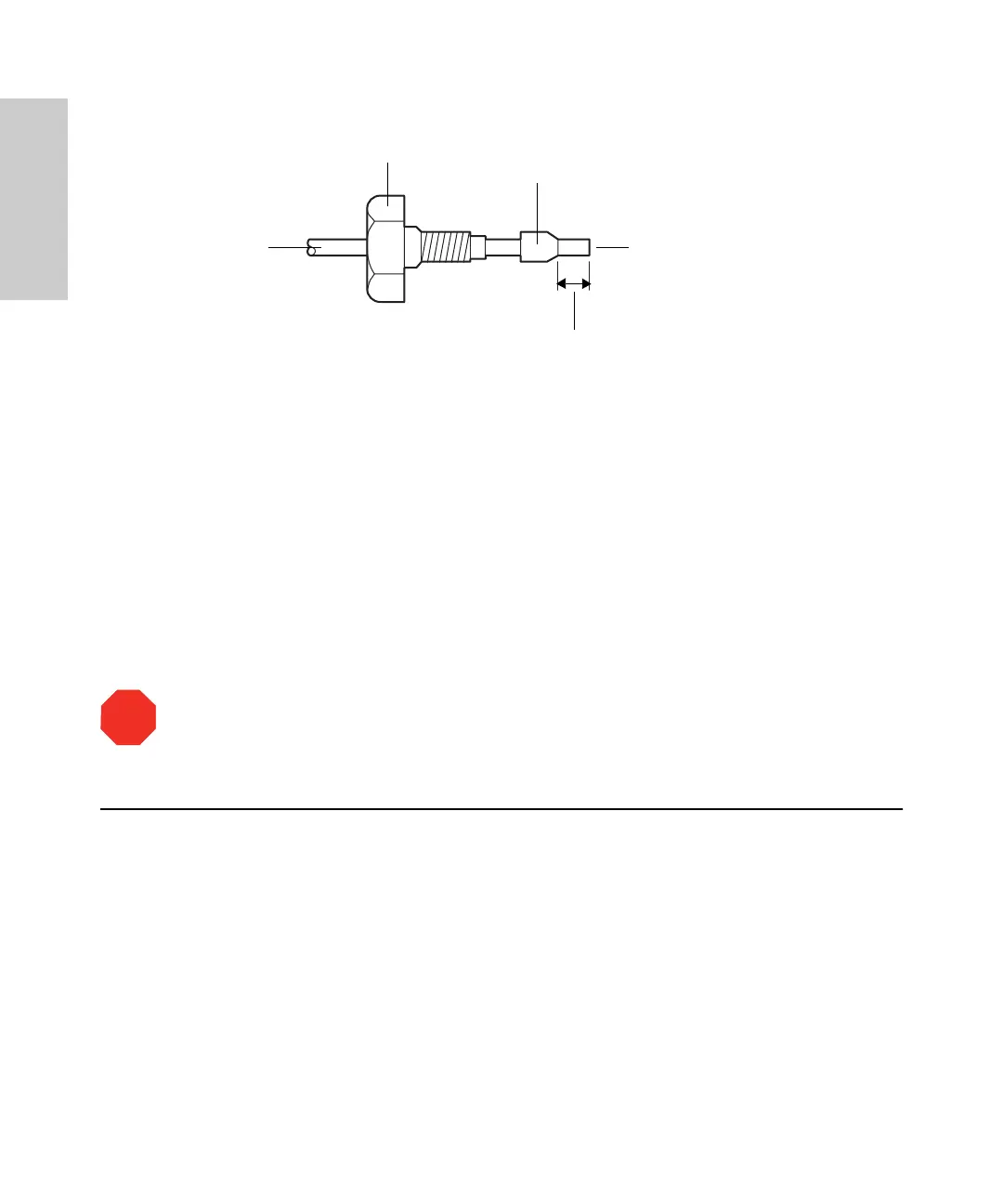

Figure 1-7 Compression Screw Assembly

4. Bottom one end of the column outlet tubing in the fitting seat of the column

outlet, then tighten the compression screw about 3/4-turn past finger-tight (using

the 5/16-inch open-end wrench).

5. Bottom the other end of the tubing in the fitting seat of the detector inlet, then

tighten the compression screw as in step 4.

6. Bottom one end of the detector outlet tubing with the compression fitting in the

fitting seat of the detector outlet, then tighten the compression screw about

3/4-turn past finger-tight. Insert the other end of the tubing in the waste

container.

Attention:

To avoid damage to the flow cell, avoid pressures approaching the maximum

pressure for the analytical flow cell, 1000 psi (70 kg/cm

2

).

1.6 Startup/Shutdown

Follow the procedures in this section to ensure reliable detector performance.

Startup

To start up the 996 detector:

1. In your instrument method, set the solvent delivery system or pump to deliver 1

mL/min of degassed mobile phase. For details, refer to the “Waters 2690

Separations Module Properties” or the “Waters 600 Properties” topic in the

Millennium

32

Online Help

Find tab.

Compression

Screw

Ferrule

TP01139

End Must Be Straight

and Smooth to Prevent

Dead Volume

Tubing

Distance Determined by

the Union or Column Fitting

STOP

Loading...

Loading...