上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

- 98 - Specialized, Concentrated, Focused

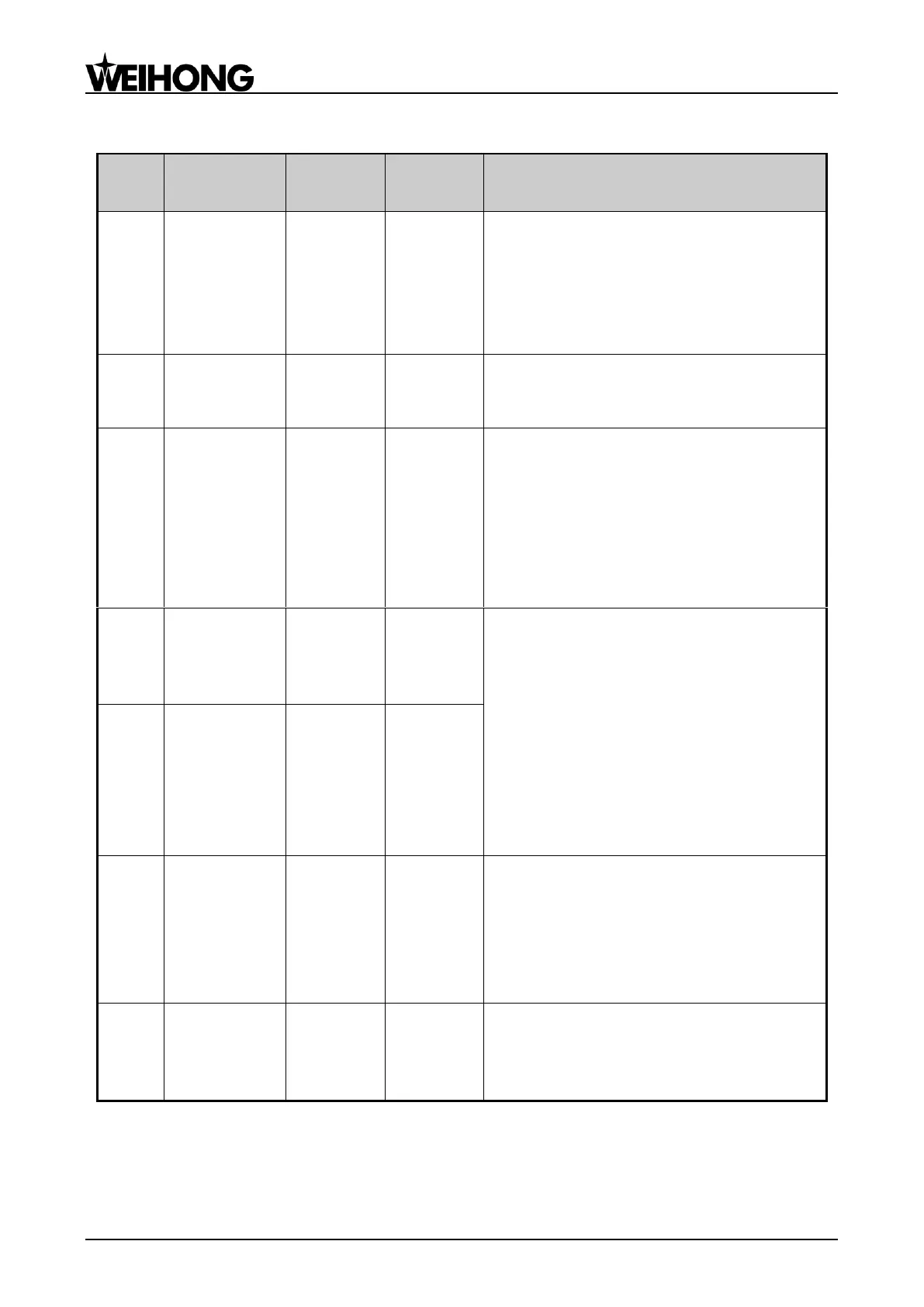

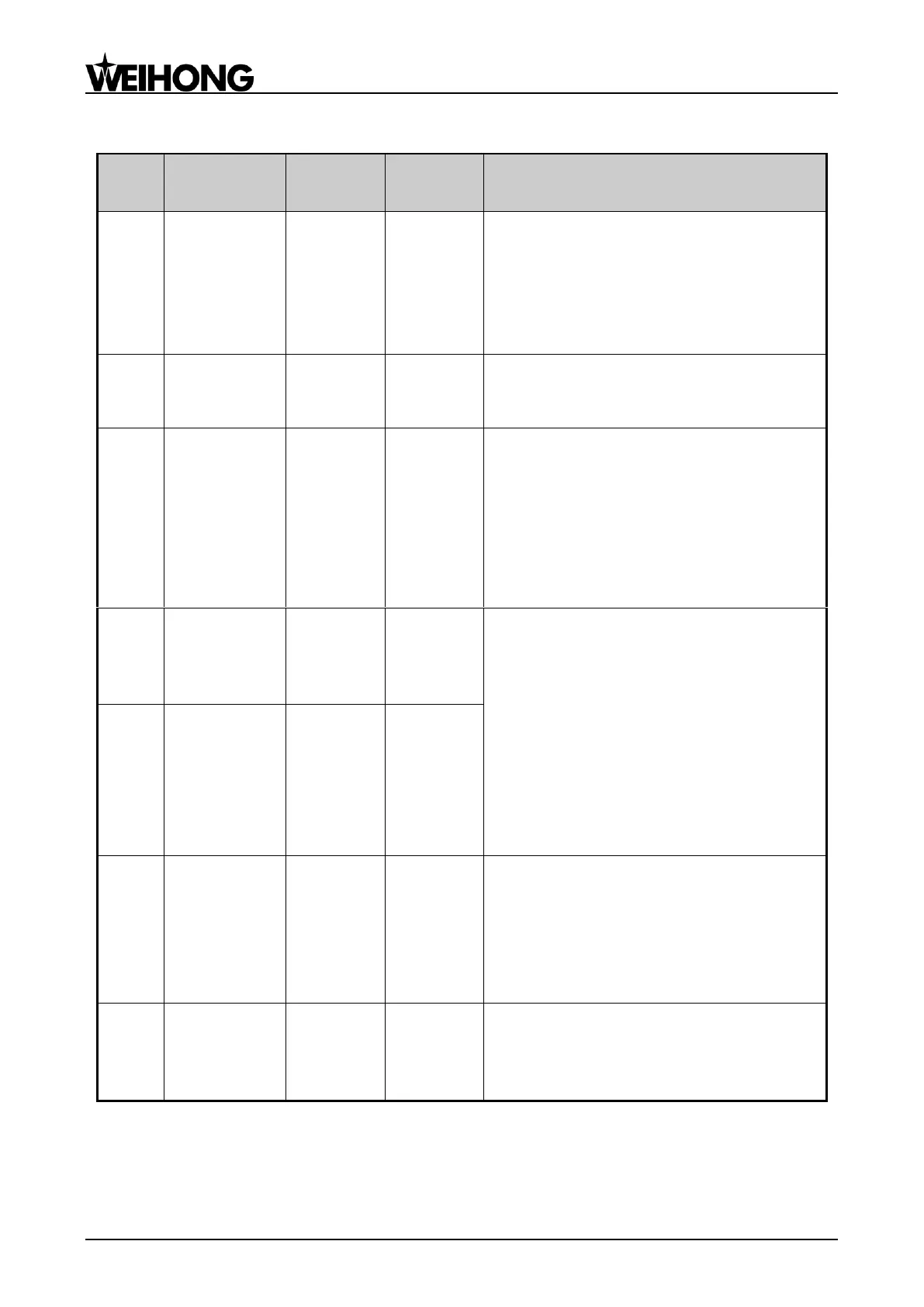

5.4.2.11 Parameter Setting of DELTA ASDA-B2 Servo Driver

Monitor if the number of sent and received

pulses is correct by setting this parameter. In

Weihong control system, the correct quantity

of pulses sent by control card is detected by

pulse inspection in order to determine

whether there is electrical interference.

External pulse

train input

type

X=2: pulse + direction;

Z=1: negative logic

Z=0: during control mode switching, DIO is

maintaining the set value. Since switching

control mode is not used, Z=0;

Y=0: forward rotation (CCW) (from the view

of load);

Y=1: the rotation direction is reversed.

X1X0=00: position control mode

Electronic

Gear Ratio

(Numerator)(N

1)

N1/M= mechanical deceleration ratio × 4 ×

encoder pulses× pulse equivalent / pitch.

Representative value: encoder

pulses=40000, pitch =5mm, pulse

equivalent=0.001, deceleration ratio = 1,

calculation as below:

N1 / M = 40000×4×0.001/5 = 32/1, N1=32,

M=1;

When the multi-electronic gear ratio is not

used, P2-60 ~P2-62 are not required.

Electronic

Gear Ratio

(Denominator)

(M)

Encoder

output pulse

number

Set according to the parameter setting of

―Frequency Division Pulses of PG (X4)‖.

Typical value: pulse equivalent 0.001, screw

pitch 10mm without a reduction box,

P1-46=10000; screw pitch 5mm,

P1-46=5000.

X1X0=01: digital input (DI1 = SON)

corresponds to 9th pin of CN1.

X2=1: set DI1 input as NO (normally open)

a-contact point.

Loading...

Loading...