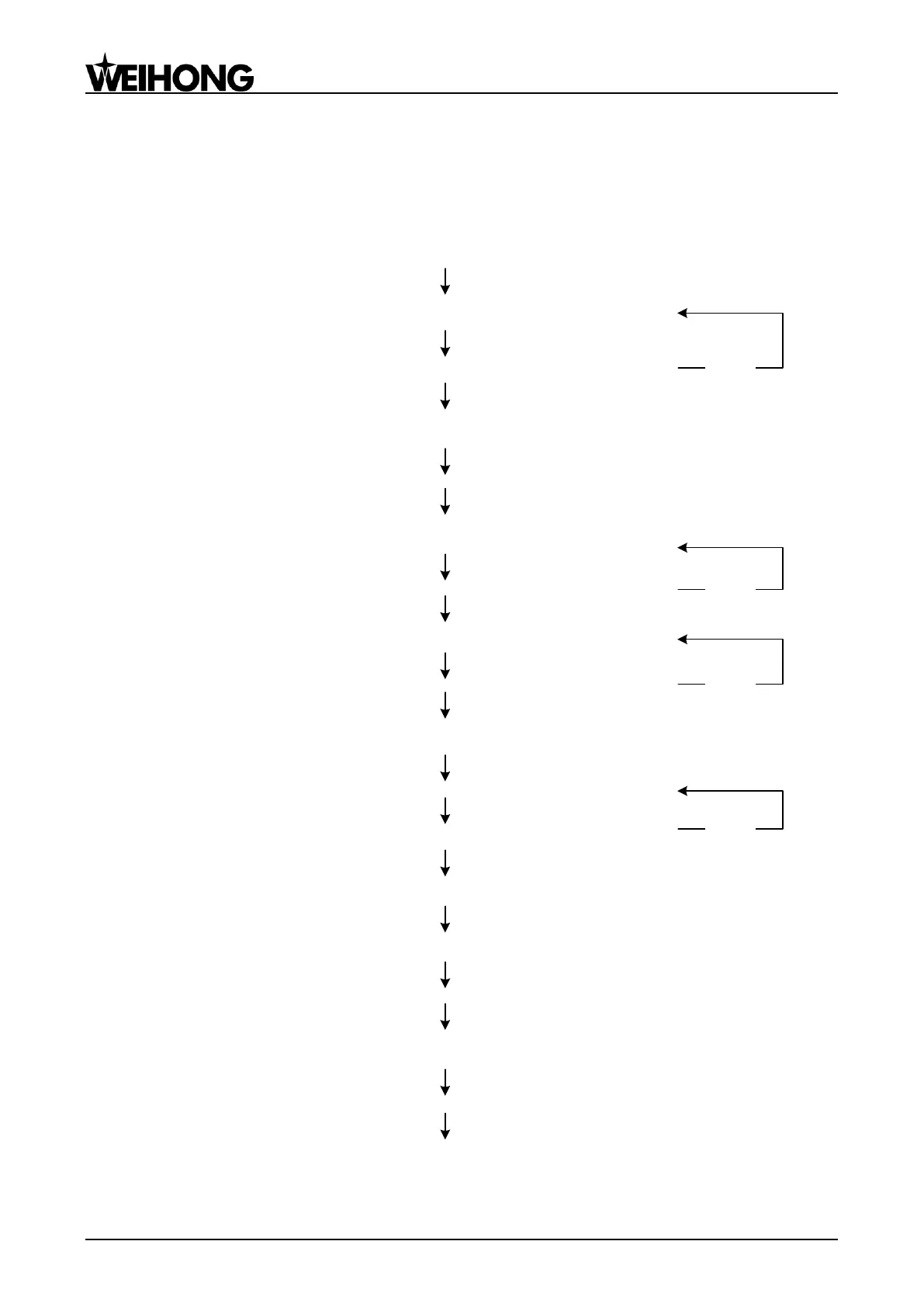

Do connections and supply power

Debugging starts

Power lamps of controller and terminal board, and signal lamp of home

switches are ON

Do connections and power on controller, machine signal system and

terminal board

True

Change port polarity in the software

Change the polarities of inputs according to the hardware (e.g. home

switches, limit switches and E-stop button)

Check connections and short circuit an input and COM on the

controller

The LED of the input turns on and the software receives the signal

Click the ―TestOn‖ and ―TestOff‖ buttons in the software

and see whether the LED of the output changes accordingly

The LED of the output changes accordingly

Set inverter parameters

Set inverter parameters, like max. and min. operating frequency and

source of external command

Check wirings and inverter parameters

Spindle rotates in the right direction and runs at speed according to the

setting value

Set relative parameters of servo driver

Please set them according to Section 5.4

Set pulse equivalent in manufacturer parameters of NcStudio

Please set it according to Section 5.3

Manually move machine tool to confirm the correctness of directions of each axis

Verify the settings of electronic gear ratio and pulse equivalent

Set worktable stroke and back to REF. point parameters in manufacturer parameters

Debugging completed

(1)

(2)

Electrify the electrical box and check

(3)

Check IOs of the controller

(4)

True

True

(5)

(6)

(7)

(8)

(9)

Alter the axis directions in the system manufacturer parameters or the

relative parameters of servo driver

(10)

False

False

False

False

True

Fig. 4-1 Process of machine tool debugging

Loading...

Loading...