71

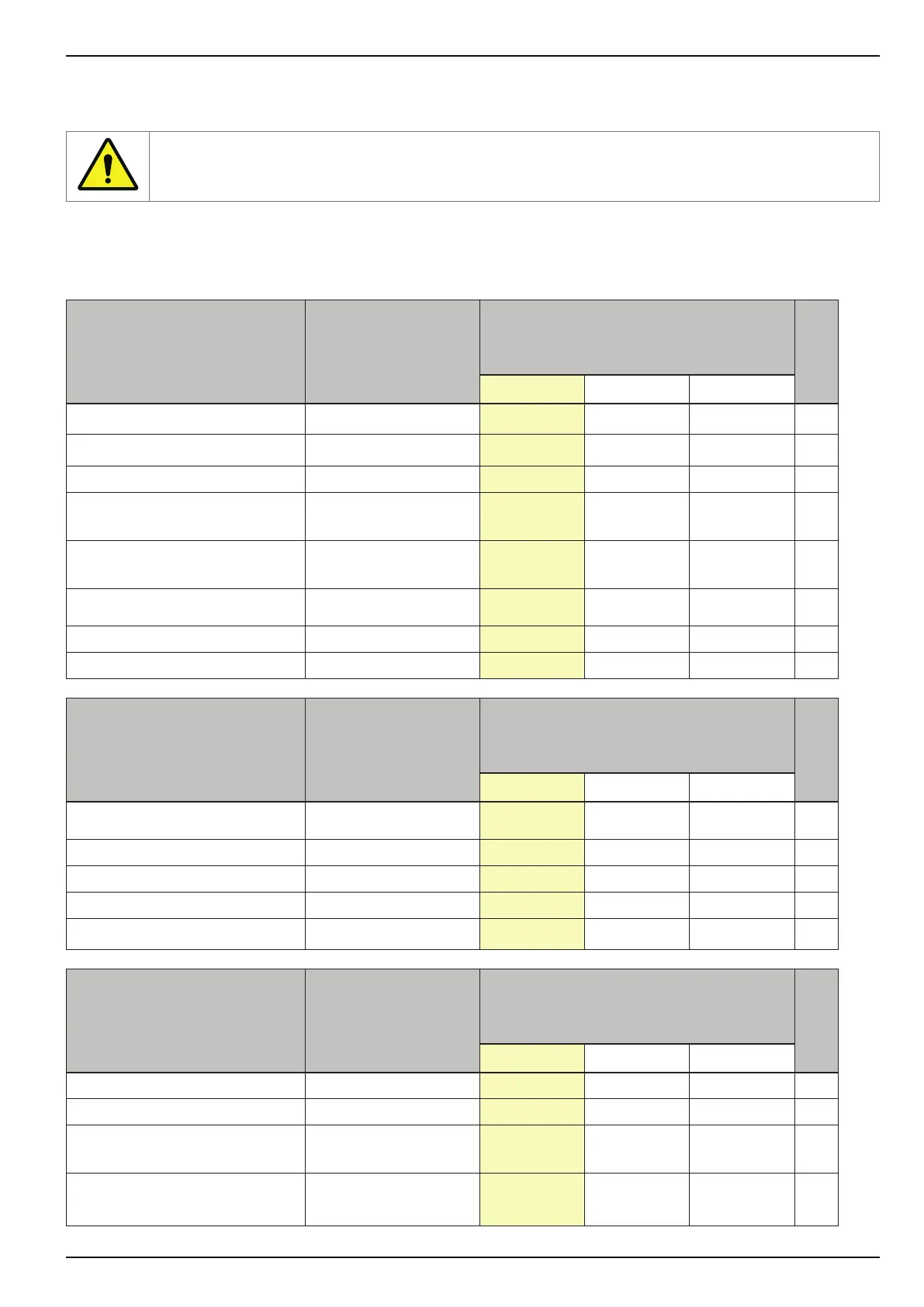

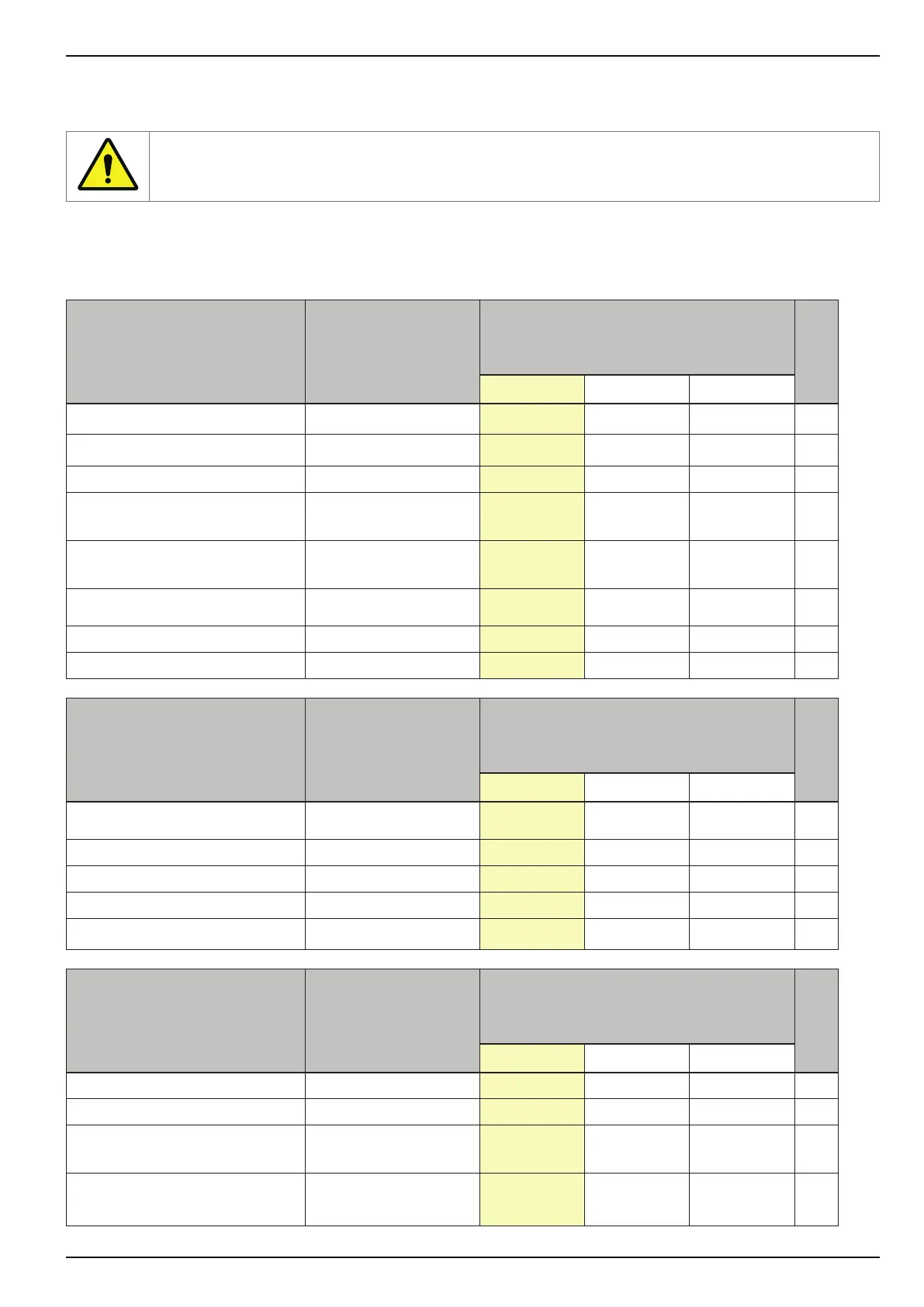

Appendix: Maintenance schedule

704 67 020 00 _ 111

OPERATING INSTRUCTIONSGF Robimat XL / XM

1 = clean

2 = test/ check

3 = lubricate

4 = replace/ exchange

OK

12 Months or

30,000

1)

24 Months or

60,000

1)

36 Months or

90000

1)

Is the machine standing safely, no

tilting, rmly secured?

2 2 2

Does the glass door close without

any resistance?

2 2 2

External housing 1 1 1

Coach bolts at top and bottom of

glass door

Special lubricant

e. g. Microlube GL 261

part no. 998 90 037 01

2+3 2+3 2+3

Locking hook

Special lubricant

e. g. Microlube GL 261

part no. 998 90 037 01

3 3 3

Flap to delivery unit

Torsion spring

2 2 2

Seal 2 2 2

Locking function 2 2 2

1 = clean

2 = test/ check

3 = lubricate

4 = replace/ exchange

OK

12 Months or

30,000

1)

24 Months or

60,000

1)

36 Months or

90000

1)

Lint lter

(directly under the slide-out drawer)

Brush, air 1 1 1

Condenser Brush, air 1 1 1

Compressor Rinsing water 1 1 1

Evaporation tray Rinsing water 1 1 1

Connecting gaskets, front, rear + left,

on the right side of the housing

Vaseline, rubber treatment 1 +2 +3 1 +2 +3 1 +2 +3

1 = clean

2 = test/ check

3 = lubricate

4 = replace/ exchange

OK

12 Months or

30,000

1)

24 Months or

60,000

1)

36 Months or

90000

1)

Insulating glass panel

Rinsing water 1+2 1+2 1+2

Door seal Vaseline, rubber treatment 2+3 2+3 2+3

Locking coach bolts

Special lubricant

e. g. Microlube GL 261

part no. 998 90 037 01

2+3 2+3 2+3

Lock

according to

manufacturer’s

specications

2+3 2+3 2+3

ATTENTION! Risk of injury!

Maintenance work may be carried out only by a service engineer or specially trained personnel.

This maintenance schedule is purely to inform the machine operator about maintenance work and intervals (refer to

Technical manual).

Loading...

Loading...