16

2. For the Installer

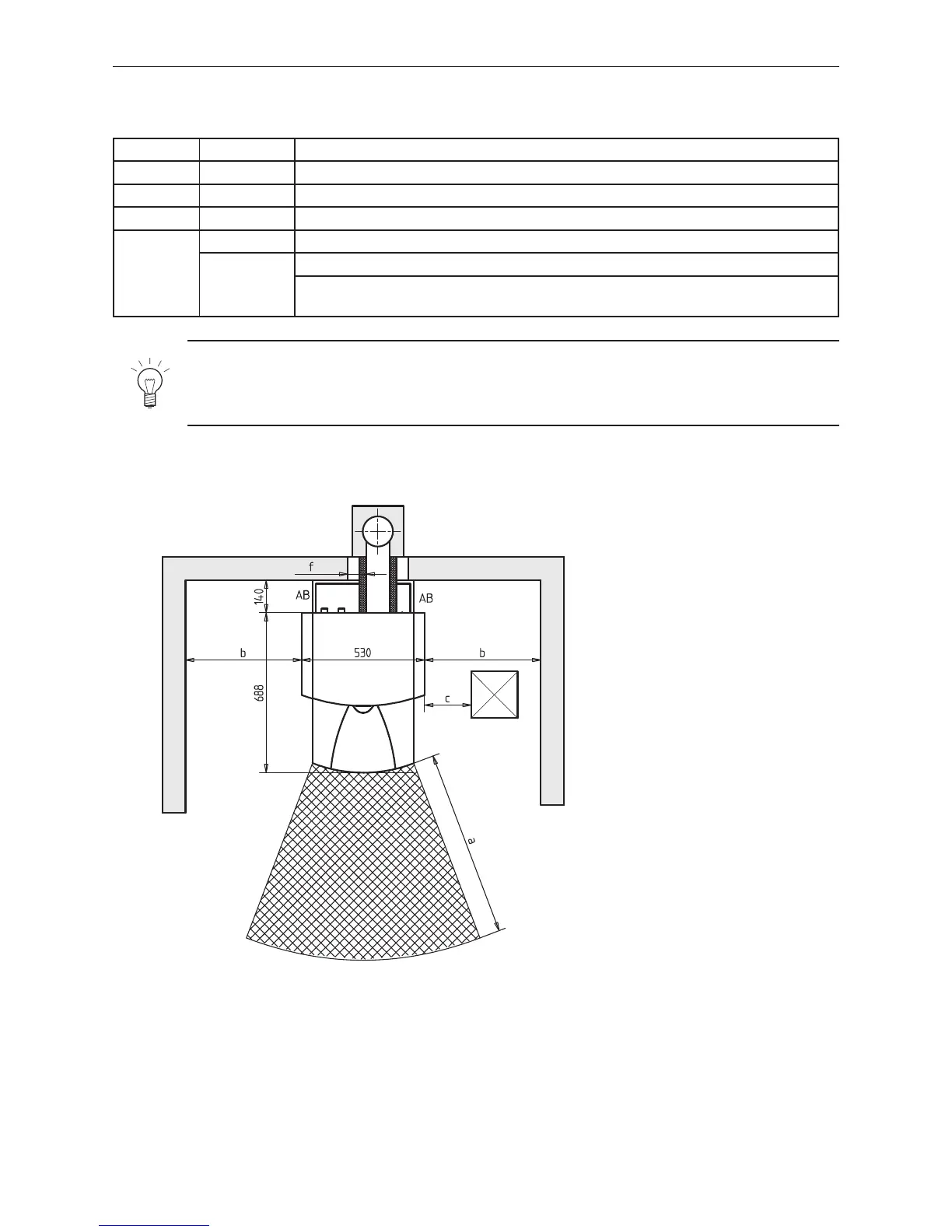

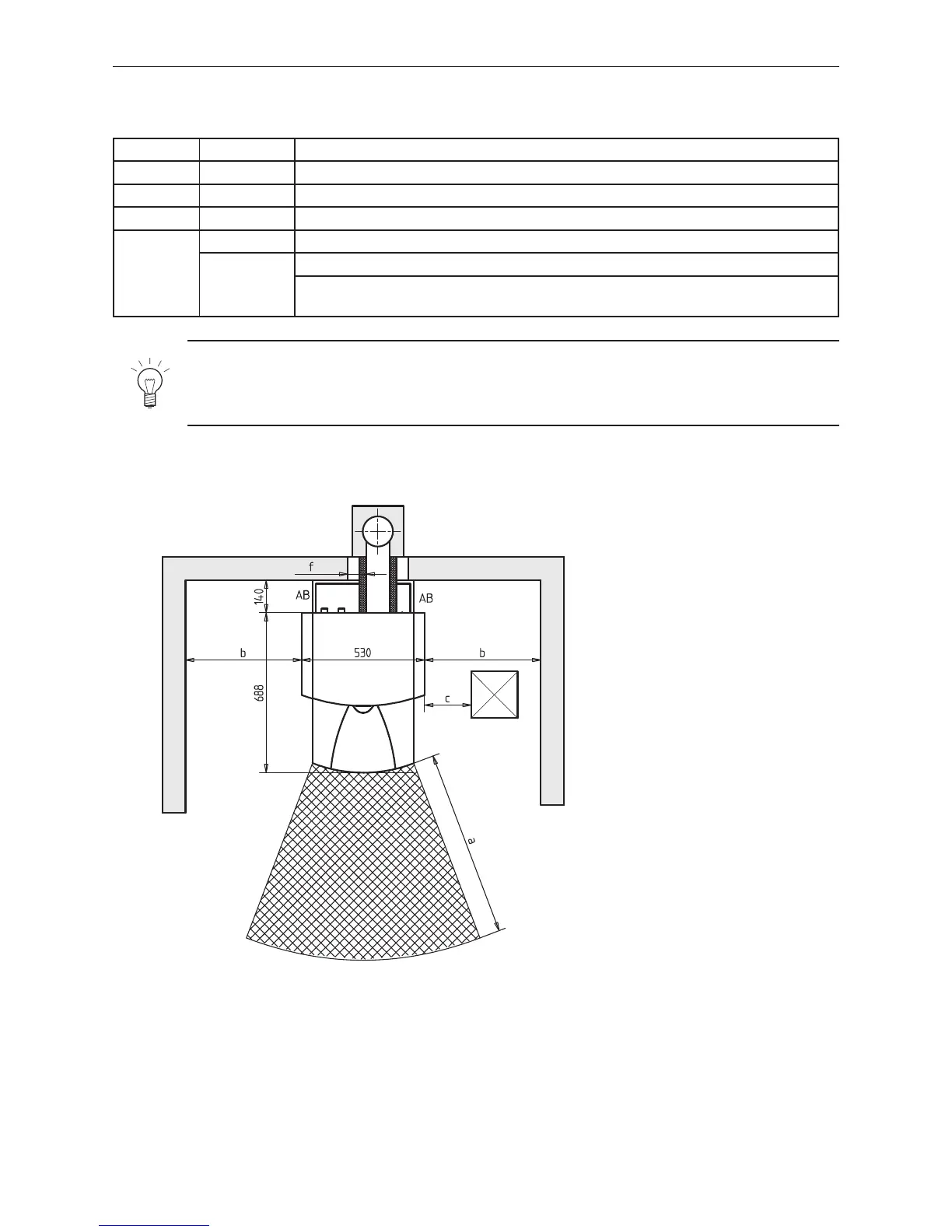

2.6.2 Minimum service clearances with flue gas tube connection

straight back

Dimension Clearance Description

a 800 mm Minimum clearance in radiation area (front window) from flammable materials

b 600 mm Minimum lateral clearance from non-movable objects (e.g. wall)

c 50 mm Minimum lateral clearance from movable objects (e.g. furniture)

f

400 mm Minimum clearance from flammable walls with non-insulated exhaust pipe

200 mm

Minimum clearance from flammable walls with insulated exhaust pipe (20 mm)

2

Minimum clearance from flammable walls with tested double-walled insulated

exhaust pipe, acc. to accreditation of connecting piece

3

Note!

The intake air line must be non-flammable (e.g. flexible aluminium tube) if the exhaust pipe is unin-

sulated.

If the walls are non-flammable, there are no fire protection reasons for a minimum service

clearance from the exhaust pipe and no need to insulate the exhaust pipe.

Fig. 7 FireWIN – view from above

AB ........ Cover plates (accessories:

FIRE 025 or FIRE 026)

1 When the fully automated feed unit FIRE 040 is installed subsequently, the pellet flue-connected boiler must be closed again by a heating expert. Subsequent

installation is highly complicated and can only be done by our customer service, with charging based on the actual work done.

2 Technical data for exhaust pipe insulation: Mineral wall insulation; melting point: >1000 °C; thermal conductivity: < 0.04 W/mK

3 The minimum service clearance is determined by the design specifications (Ø of the double pipe) of the flue gas system used or the minimum service clea-

rances demanded in the accreditation.

Loading...

Loading...