7

2. For the Installer

2.2 System

2.2.1 Area of use

For heating buildings acc. to EN 12831.

The boilers are designed and approved as heat generators for hot water heating systems with a permissible flow

temperatures of up to 90°C. They may be installed only in sealed systems. The maximum flow temperature is

factory-set at 75°C.

2.2.2 Heating fittings

Safety valve 2.5 bar (upplied as standard with FireWIN versions UAM and UAML):

The safety valve is type-tested (code letter “H”). Only safety valves of this kind are allowed to be used. The client

must provide a safety valve in FireWIN versions without heating fittings. The drainage line from the safety valve

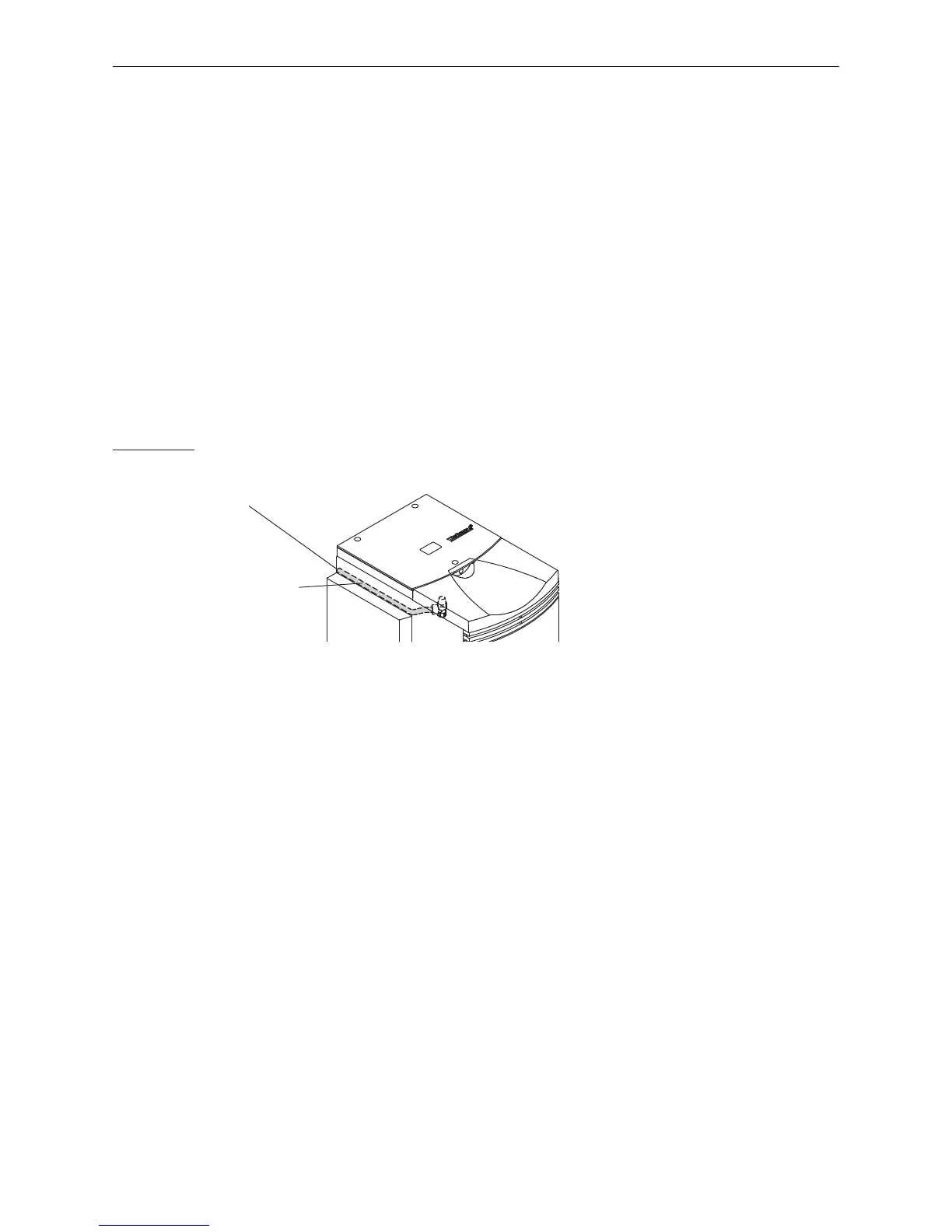

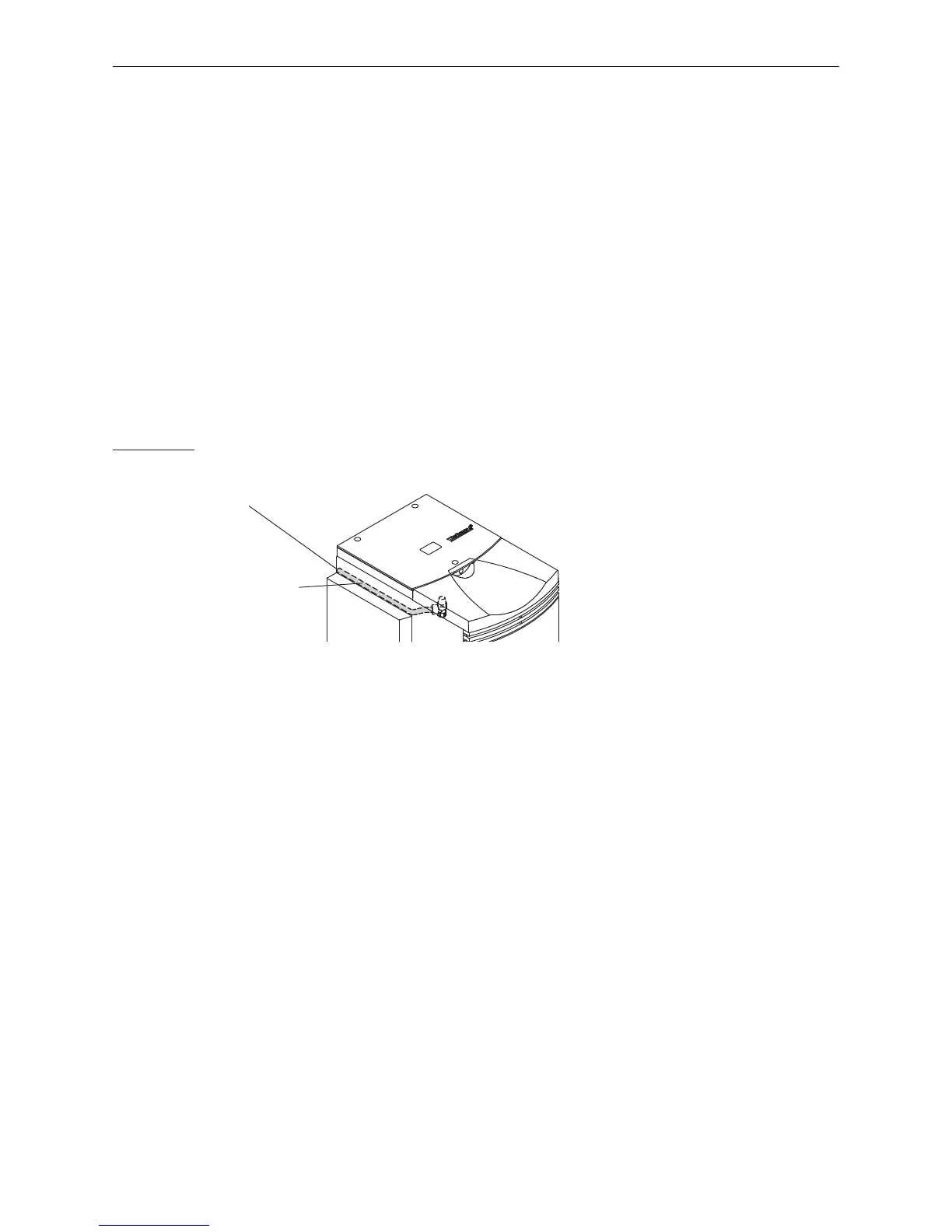

must be provided by the client. The line can be routed backwards on the left side between the pellet reservoir

container and the left side panel – Fig. 2. Break out the cut-out on the rear wall.

Please note:

– Have the function checked by an expert on start-up and at least once a year.

Fig. 2 Drain line from safety valve

Break out the cut-out in the rear wall

Drain line from safety valve

Expansion tank (upplied as standard with FireWIN versions UAM and UAML):

of the expansion tank depends of the parameters of the heating system and must be calculated on a case-by-

case basis. The flat pressure expansion tank installed in FireWIN versions is designed for a feed pressure of

1.0 bar and a content of 12 l. An additional expansion tank must be provided by the client if this volume is not

sufficient.

Pressure gauge (in FireWIN versions UAM and UAML installed at the front behind the cladding door as standard):

The system pressure should be at least 1 bar. Check the system pressure, more frequently at first and then

twice a year later on.

Bleeder valve

Installed as standard in all boilers under the front cover. In addition, the variants UAM and UAML also have a

manual ventilation function behind the left side panel at the feed above the circulation pump. In boilers without

fittings, ventilation is to be provided on the feed if the feed is routed downwards.

A low-water cut-off:

A low-water cut-off is not required for systems providing up to 300 kW nominal thermal output, if it can be as-

sured that excess heating will not result from a lack of water in the system.

The boilers are equipped with an electronic temperature regulator and a type-tested safety temperature limiter.

If the boiler is above the radiators, then a low-water cut-off must be installed.

Loading...

Loading...