Maintenance1715−1/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

2/ 2

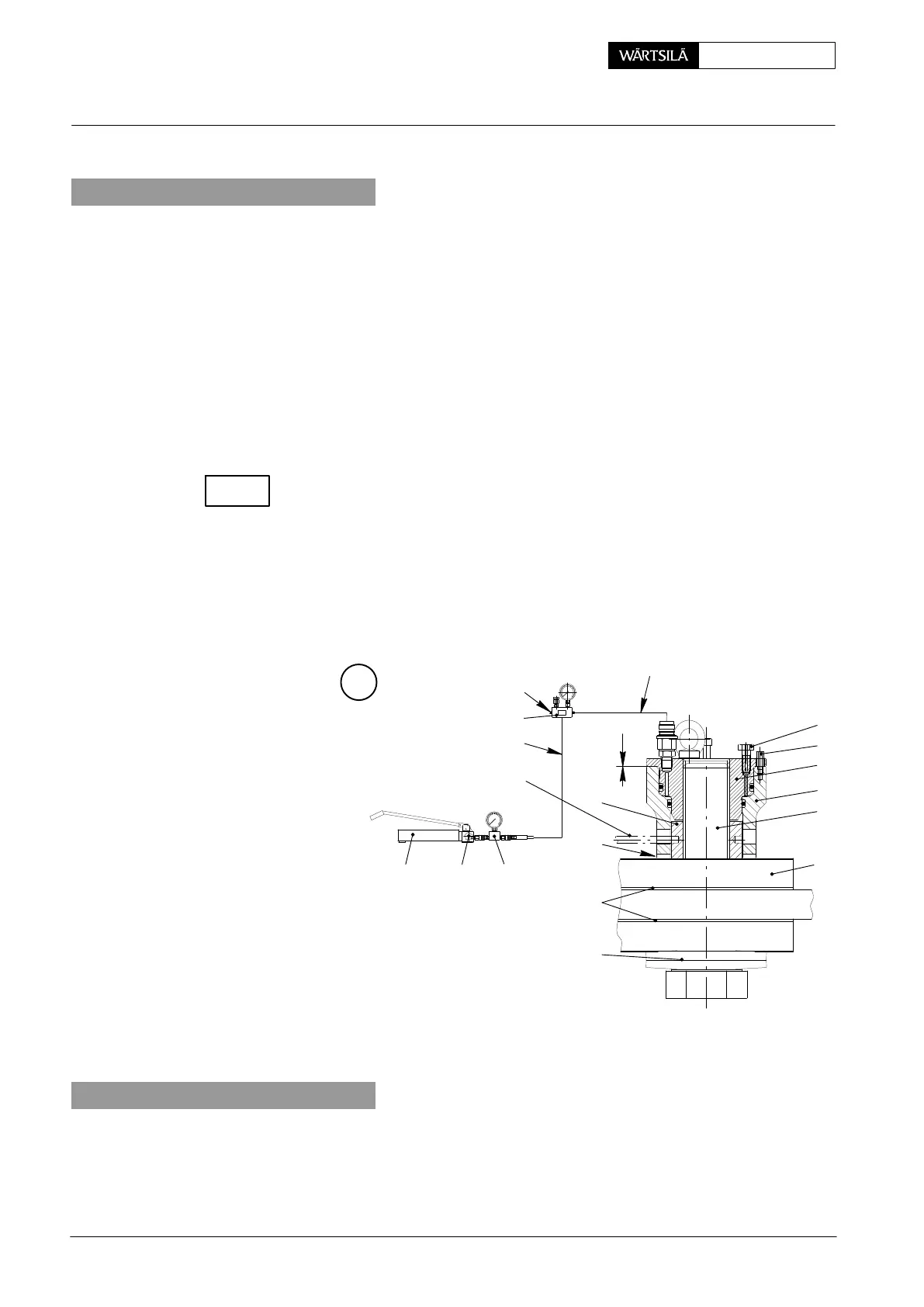

2. Checking the pre-tension

⇒ Clean the thread of the screw and the seating surface. Subsequently apply

MOLYKOTE to the thread.

⇒ Place pre-tensioning jack 94145 on the screw to be checked, and screw it

completely down with vent screw 8 open until there is only little or no clearance

at ’x’ (Fig. ’B’).

⇒ Connect pre-tensioning jack 94145 with HP oil pump 94931 as shown in Fig.

’B’, whereby one side of hydr. distributor 94934A must be plugged with plug

piece 94934E.

⇒ Close relief valve ’EV’ at the HP oil pump, then actuate the HP oil pump until

the oil comes out without bubbles from the opened vent screw 8.

⇒ Close vent screw 8, tension the screw with 150 bar and keep the pressure

constant.

Check with feeler gauge through slot ’KO’ if there is any clearance between nut 4

and its seating.

⇒ If there is no clearance, this means that the tensioning condition of the screw

has remained unchanged since the last check. The pressure can be released

to zero and the pre-tensioning jack removed.

Should a clearance be found, nut 4 must be tightened down onto its seating

with rod 94005D while the pressure is kept at 150 bar (check with feeler

gauge). Subsequently lower the pressure to zero.

B

8

1

94931 94932

94935A

4

94005D

KO

2

5

EV

94935

94934A

94934E

9

7

3

6

x

003.467/00

3. Loosening the screws

If the screws must be loosened, first screw on pre-tensioning jack 94145 complete-

ly, then loosen it by about ½ turn. Afterwards tension the screw with 170 bar, and

turn nut 4 back by one turn. Attention should be paid to ensure that pin 9 always

protrudes slightly compared with piston 6 on the pre-tensioning jack!

Engine Stays with Friction Shims: Checking the Pre-tension

2013

CHECK

Loading...

Loading...