Maintenance

3140−1/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

1/ 4

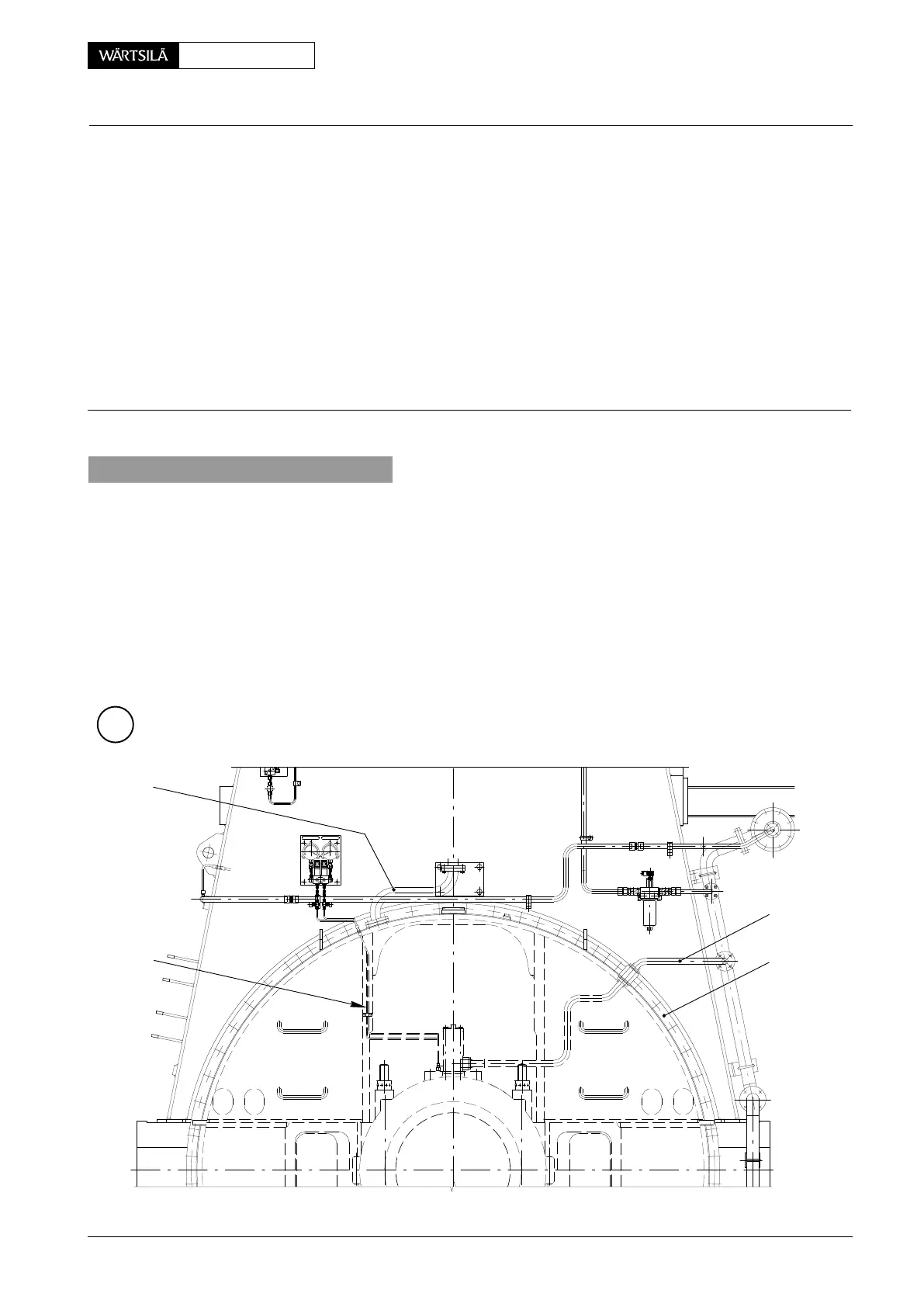

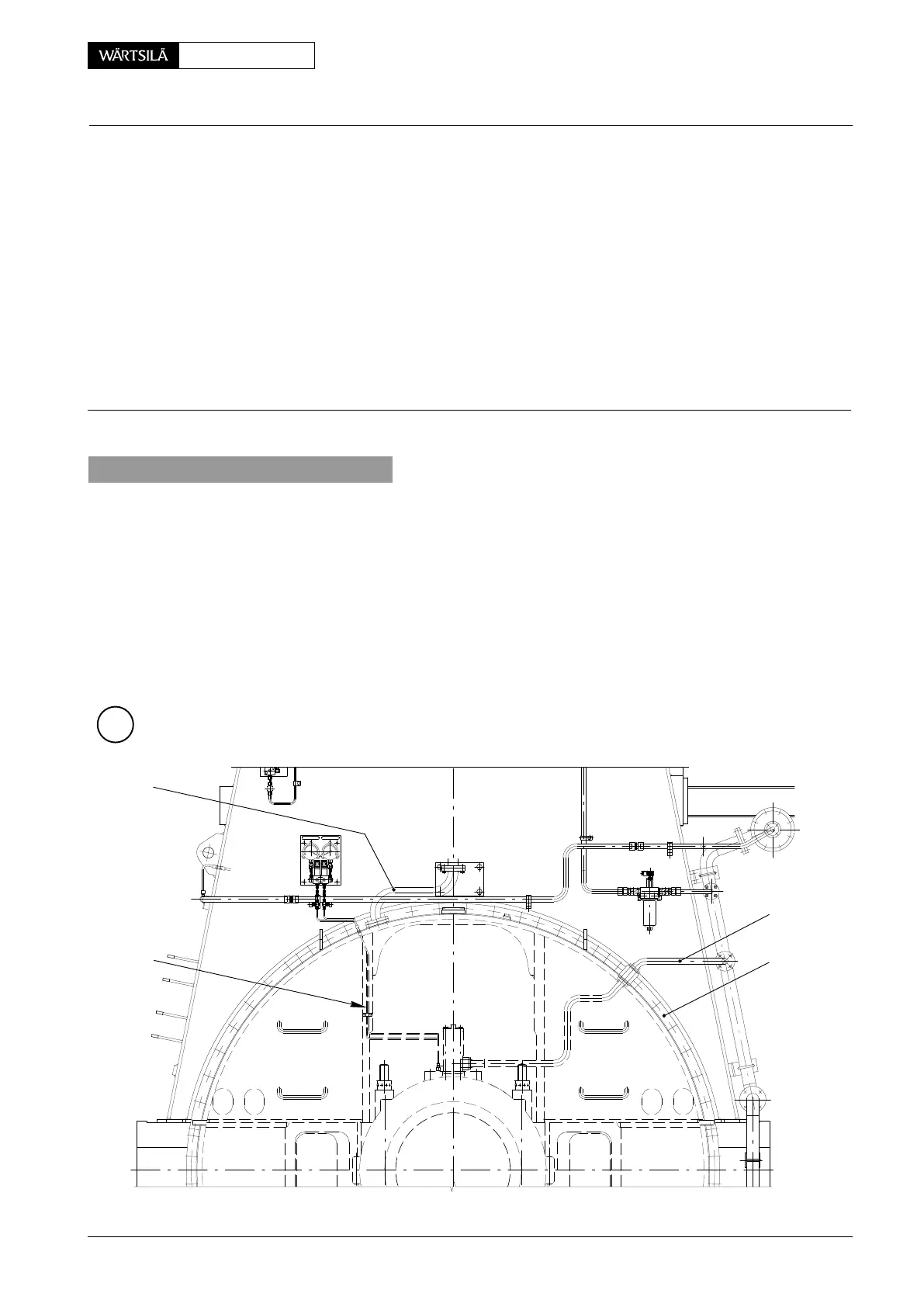

Tools: Key to Illustrations:

1 Manual ratchet (WLL 2500 kg) 94016E 1 Upper part of cylinder 12 Orifice

2 RUD-eye bolts M16 94040-M16 2 Lower part of cylinder 13 Oil inlet pipe

1 Support 94320 3 Bolt M20x150 14 Main bearing cover

1 Wire rope sling GF 94333D 4 Bolt M24x200 15 Crankshaft

5 Bolt M20x480 16 Main bearing shell

6 2-part gasket 17 Oil drain pipe

7 2-part gasket 18 Upper casing

8 Tension spring 19 Screw M16x160

9 Tension spring 20 Piping for damper

10 Housing monitoring

11 Taper pin

1. Dismantling

When the 2-part gaskets 6 or 7 has to be removed from an axial damper, proceed

as follows:

⇒ Switch off the bearing oil pump.

⇒ Remove oil drain pipe 17.

⇒ Unscrew and remove oil inlet pipes 13 and the piping for damper monitoring

20 internally and externally from upper casing 18.

⇒ Remove upper casing 18.

A

18

20

003.262/00

13

17

V2 / 2013

Axial Damper

Dismantling and Assembling

Loading...

Loading...