Maintenance

3326−2/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

1/ 6

Tools: Key to Illustrations:

1 Manual ratchet (WLL 800 kg) 94016 (H1) 1 Crank

2 Manual ratchets (WLL 1000 kg) 94016D (H2, H3) 2 Connecting rod

1 Manual ratchet (WLL 2500 kg) 94016E (H4) 3 Piston rod

1 Manual ratchet (WLL 250 kg) 94016G (H5) 4 Crosshead pin

1 Spur-geared chain block (WLL 3000 kg) 94017A (H6) 5, 5a Guide shoe

4 RUD-eye bolts (RC1) 94040−M20 6, 6a Guide shoe middle part

2 RUD-eye bolts (RC2) 94040−M30 7 Guide rail

1 Eye bolt (RC3) 94045−M10 8 Screw

1 Deviation pipe GF 94117A 9, 9a End cover

1 Working platform 94142 10 Guide way

2 Cover and lifting plate 94324

2 Holders 94325

1 Wire rope sling GF 94333D

3 Shackles (WLL 4750 kg) 94572C

2 Shackles (WLL 2000 kg) 94572I WU Wooden underlay

1. General

Risk of accident! Ensure that the crankshaft does not turn unintentionally during

all the work.

Remark: Pay attention to:

− General Guidelines for Lifting Tools 0012−1.

− Utilization of Working Platform 3301−1.

2. Preparatory works

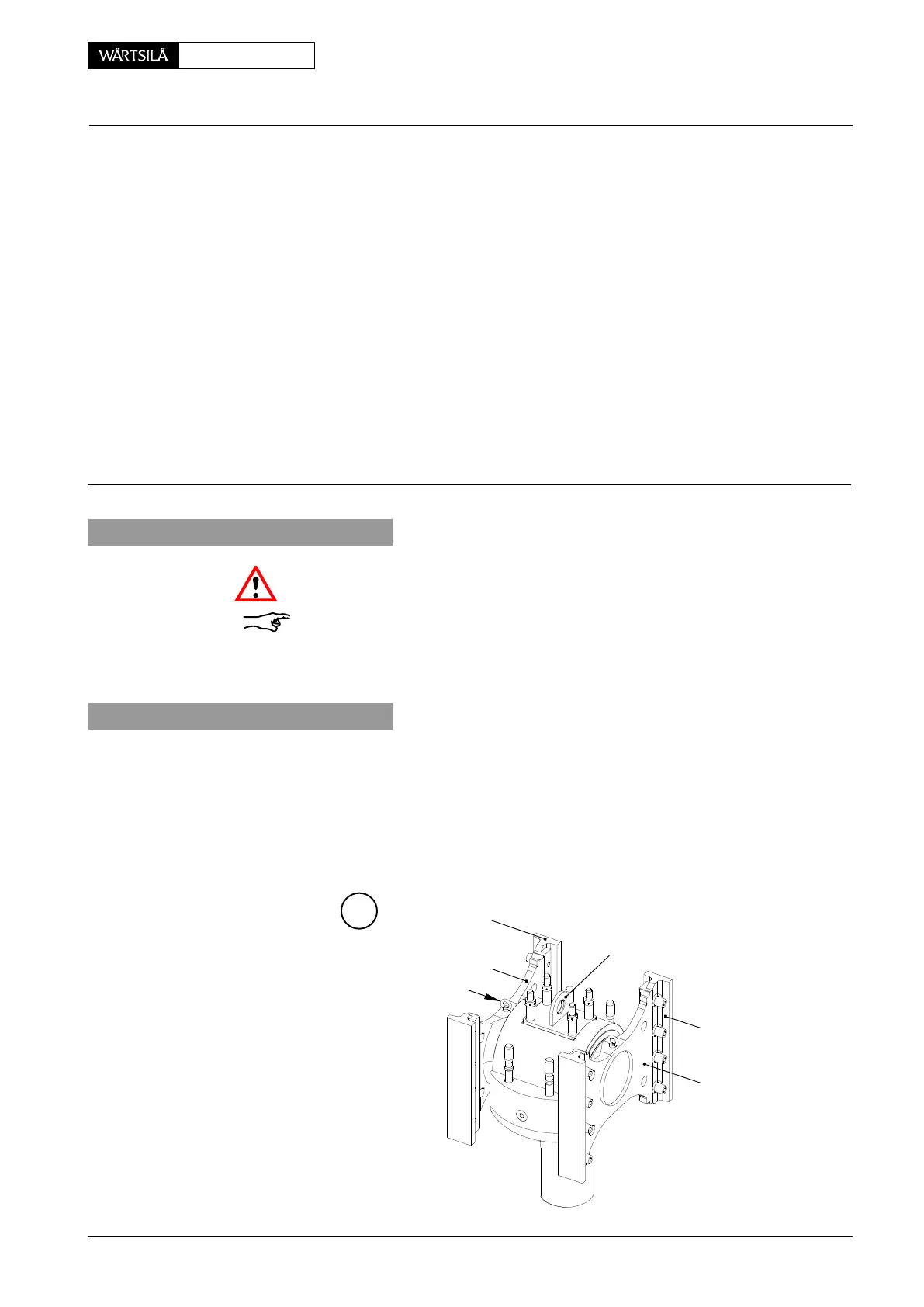

D Top end bearing cover removed (see 3303−5) and piston rod 3 suspended.

D Platform element removed.

D Relevant cylinder turned to B.D.C.

D Lifting plate 94324 mounted on crosshead pin.

D Two RUD-eye bolts ’RC1’ tightened to middle parts 6, 6a with 115 Nm.

94324

RC1

6a

6

5a

5

A

V2 / 2013

Crosshead

Removal and Fitting of a Crosshead Pin

Loading...

Loading...