Maintenance

8752−1/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

1/ 5

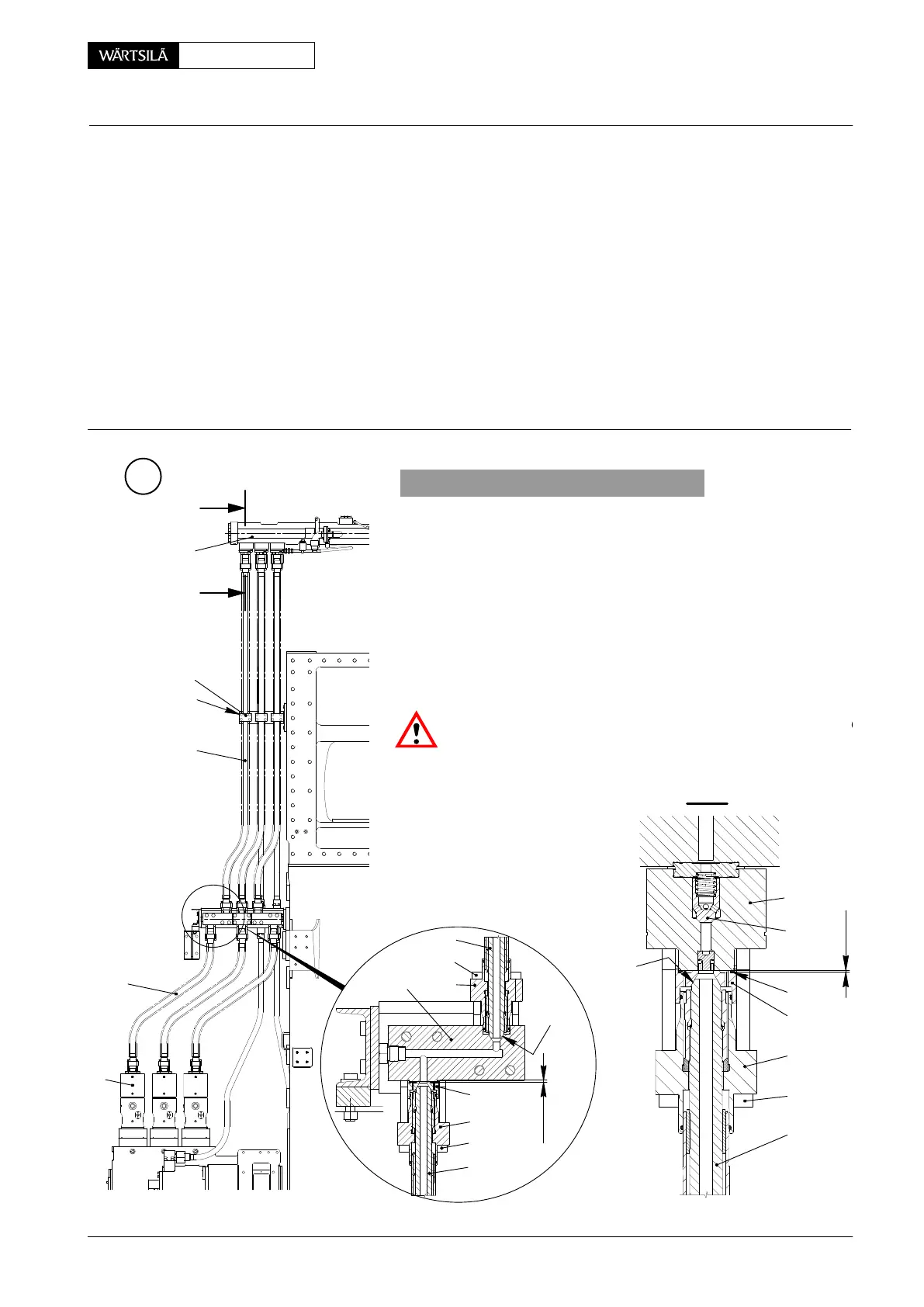

Tools: Key to Illustrations:

1 Regrinding device 94870 1 Upper HP fuel pipe 13 Screw

consisting of: 2 Lower HP fuel pipe 14, 14a Flange

1 Screw-on sleeve 94870E 3 Fuel rail 15, 15a Screw

1 Grinding tool 94870F 4 Fuel pump cover 16 Non-return valve

1 Lock nut 94870G 5 Intermediate piece 17 Leakage fuel pipe

1 Template 94870H 6 Mounting clamps 18 Claw

7 Screw 19, 20 O-ring

1 Torque wrench 8 Screw 21 Thrust ring

9 Flange DF Sealing face

10, 10a Intermediate ring EC Emery cloth

11 Valve housing HD Hand drill

12 Flange LB Leakage fuel bore

A

WCH01047

1. General

The engine must be stopped and the fuel supply pu

switched off. After approx. 10 minutes the pressure is reduc

in the HP fuel pipe and the fuel can be drained as follows:

⇒ Loosen screws 8, push back flange 9 and intermediate ri

10 (section I-I) in order to vent the pipe for draining.

⇒ Loosen screws 13, push back flange 12 and separ

lower HP fuel pipe 2 from its sealing faces. Fuel oil drai

via bores ’LB’ and leakage fuel pipe 17 (section II-II)

Non-return valves 16 prevents the fuel rail from dischargin

Risk of accident! Make sure that the steam supply is clos

before loosening the screwed connections to the heating pip

3

I - I

WCH01051

I

I

6

7

5

1

15

14

10a

14a

15a

2

11

16

10

9

8

1

DF

DF

2 mm

2 mm

20

4

1

2

HP Fuel Pipe

Removing, Fitting and Regrinding

V2 / 2013

Loading...

Loading...