Maintenance3303−1/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

2/ 2

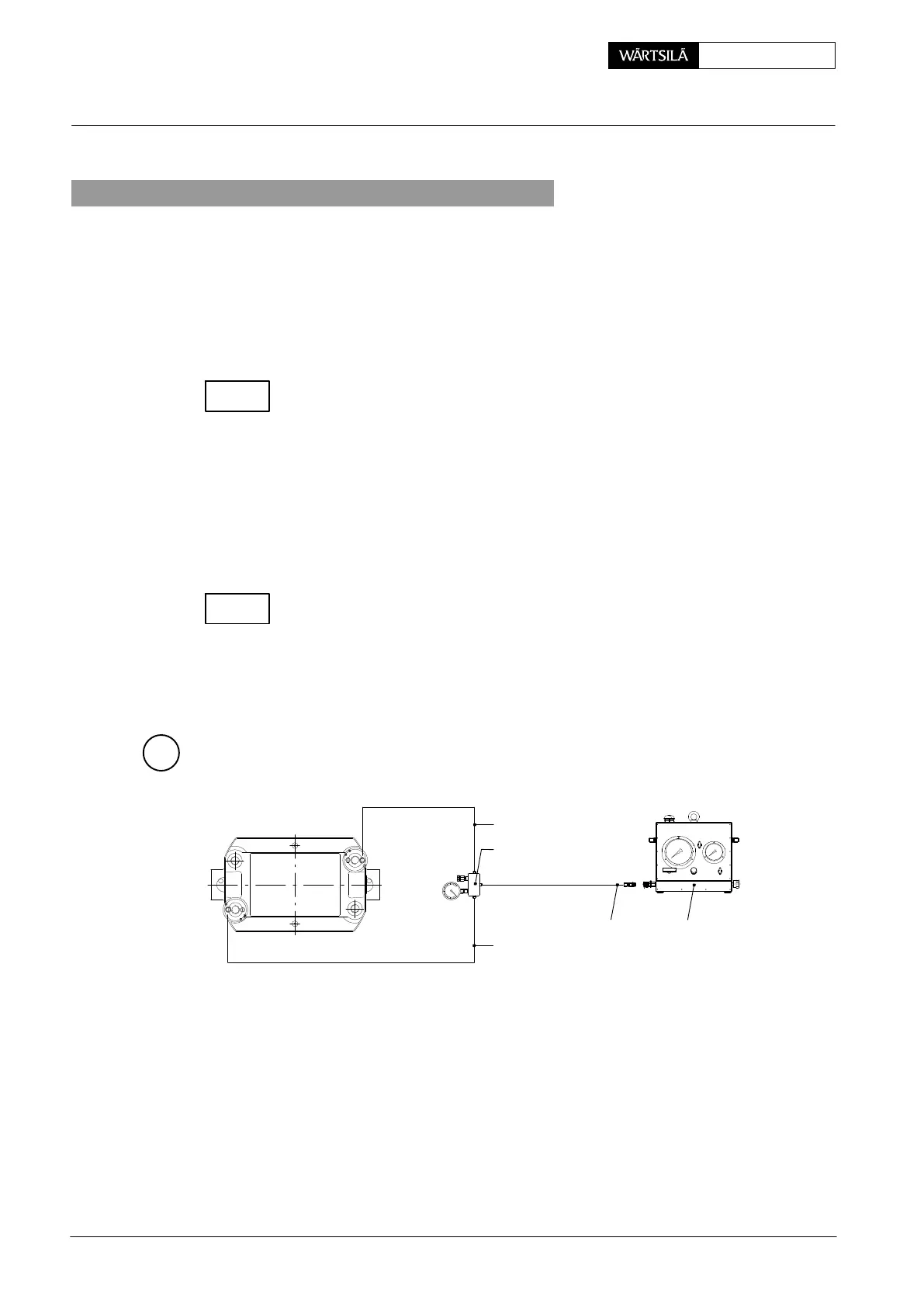

2. Loosening and tensioning the connecting rod studs

2.1 Bottom end bearing

D Tighten the nuts with a round bar and equally distribute clearance ’y’ between

the bearing halves (bearing protrusion) as shown in Fig. A.

D Tensioning of the studs of bottom end bearing 4 must be carried out in two

steps without exception, i.e. tension studs first with 300 bar (1

st

step), then

finish tensioning with 1000 bar (2

nd

step).

Based on the markings applied, check by how much the nuts were turned after pre-

tightening (1

st

step) to the 2

nd

step. Tightening angle to be about 60_ for compari-

son.

2.2 Top end bearing

D Tighten the nuts with a round bar and equally distribute clearance ’y’ between

the bearing halves (bearing protrusion) as shown in Fig. A.

D Tensioning of the studs of top end bearing 5 must be carried out in two steps

without exception, i.e. tension all elastic studs first with 600 bar (1

st

step),

then finish tensioning with 1000 bar (2

nd

step).

Based on the markings applied, check by how much the nuts were turned after pre-

tightening (1

st

step) to the 2

nd

step. Tightening angle to be about 25_ for compari-

son.

D Moreover, always carry out loosening and tightening procedures crosswise,

i.e. a/a and b/b for each step.

a

b

b

a

ARRANGEMENT OF PRE-TENSIONING

JACKS 94315

B

94942

94935A

94934A

94935A

94935

2013

Loosening and Tensioning the Connecting Rod Studs

CHECK

CHECK

Loading...

Loading...