Page 20 of 46

WITT-GASETECHNIK GmbH & Co KG

Gas Safety- & Control Equipment

7.2.3 Top Level Main Menu

The top level main menu is the entry for all other menus respective submenus. It is on the top of

the menu tree. Within this menu the operator can select where to go from here. If the item “Opera-

tion” is selected (as shown) the MFA 9000 will return to the Operation screen by pressing <EN-

TER> or <UP>. To get access to a submenu, first select the appropriate item and press <ENTER>.

A menu path given in the following sections will always start at the top level main menu.

7.3 Calibration

If the instrument is in the “safe mode”, the operator needs the so called “Operator Code” in order to

get access to calibration functions. By default the operator code is set to “111.000”. Gain calibration

is only accessible subsequent to an offset calibration. In many cases single point calibration is suf-

ficient for a proper performance of the instrument. This is the offset calibration and means a parallel

shift of the straight calibration line. If a gain calibration follows the offset calibration also the slope of

the straight calibration line is recalculated.

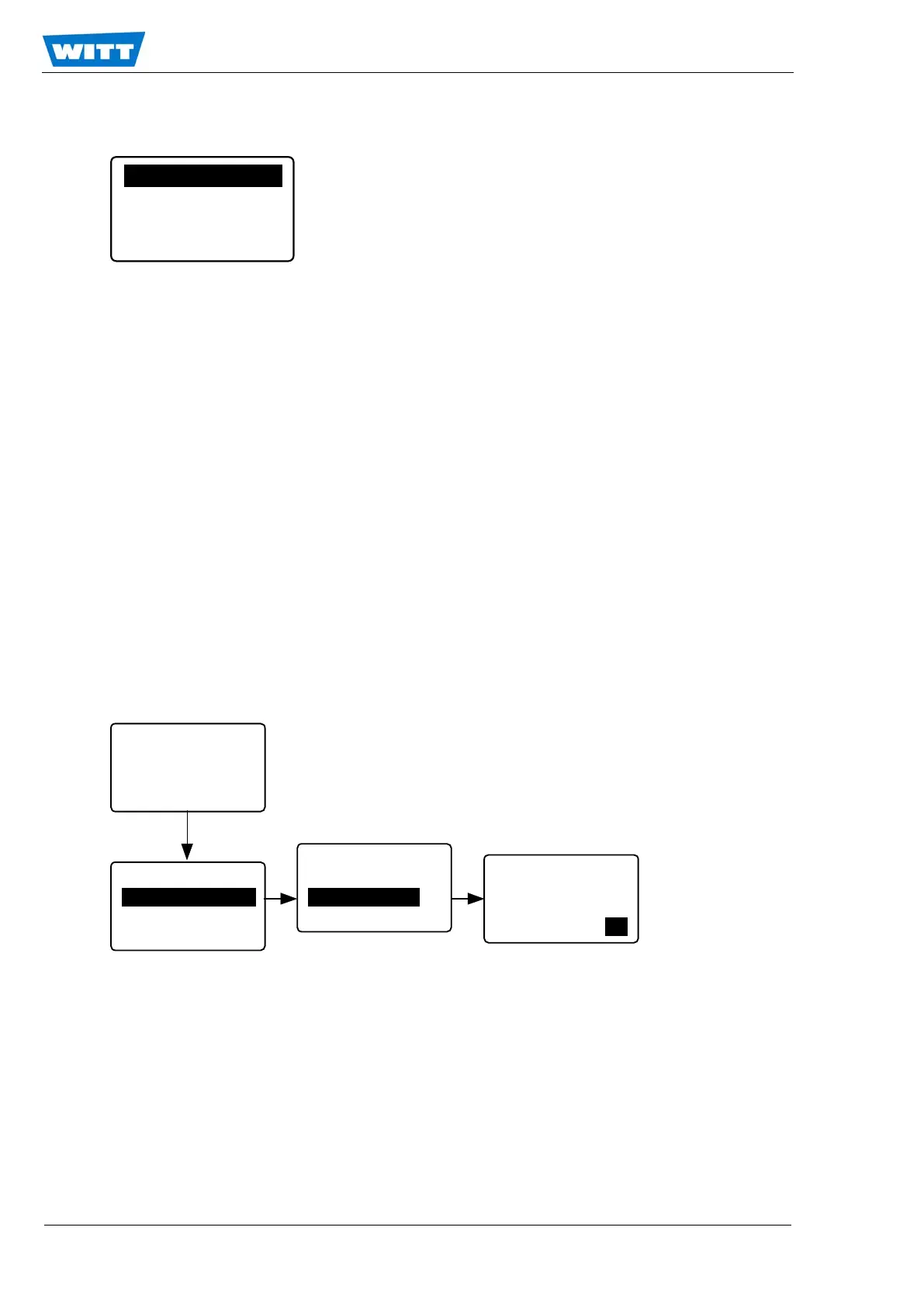

7.3.1 Set Offset Gas Concentration

The offset gas menu gives the operator the possibility to set the offset gas concentration in accord-

ance with the bottle gas the operator intends to apply. While performing an offset calibration the

sensor must be purged with offset gas. In most applications the offset gas concentration is close to

starting point of the desired measuring range. In case the operator indent to do a single point (off-

set) calibration only, the offset gas concentration may be anywhere in the measuring range. It may

be also outside the range (substitute offset gas).

Operation

Calibration

Diagnosis

Setup

A1 A2 Er

0.30

[%] H2/N2

Operation

Calibration

Diagnosis

Setup

H2 in N2

Calibrate

Offset Gas

Gain Gas

Offset Gas

set: 0.00000

new: 0.00000

[%] ESC/

OK

Loading...

Loading...