Page 15 of 46

WITT-GASETECHNIK GmbH & Co KG

Gas Safety- & Control Equipment

6.4 Shut-down

The gas analyser has been designed for continuous operation. After a shut down of the gas analys-

ing system, the complete start-up procedure needs to be performed before full operability of the

system can be re-established!

Close all gas supplies to the gas analyser.

Disconnect the analyser from the mains.

Caution !

For technical reasons some residual gas pressure will remain trapped in the gas lines which

will be released when the inlet connections are unscrewed.

6.5 Malfunctions and rectification

6.5.1 Malfunction table

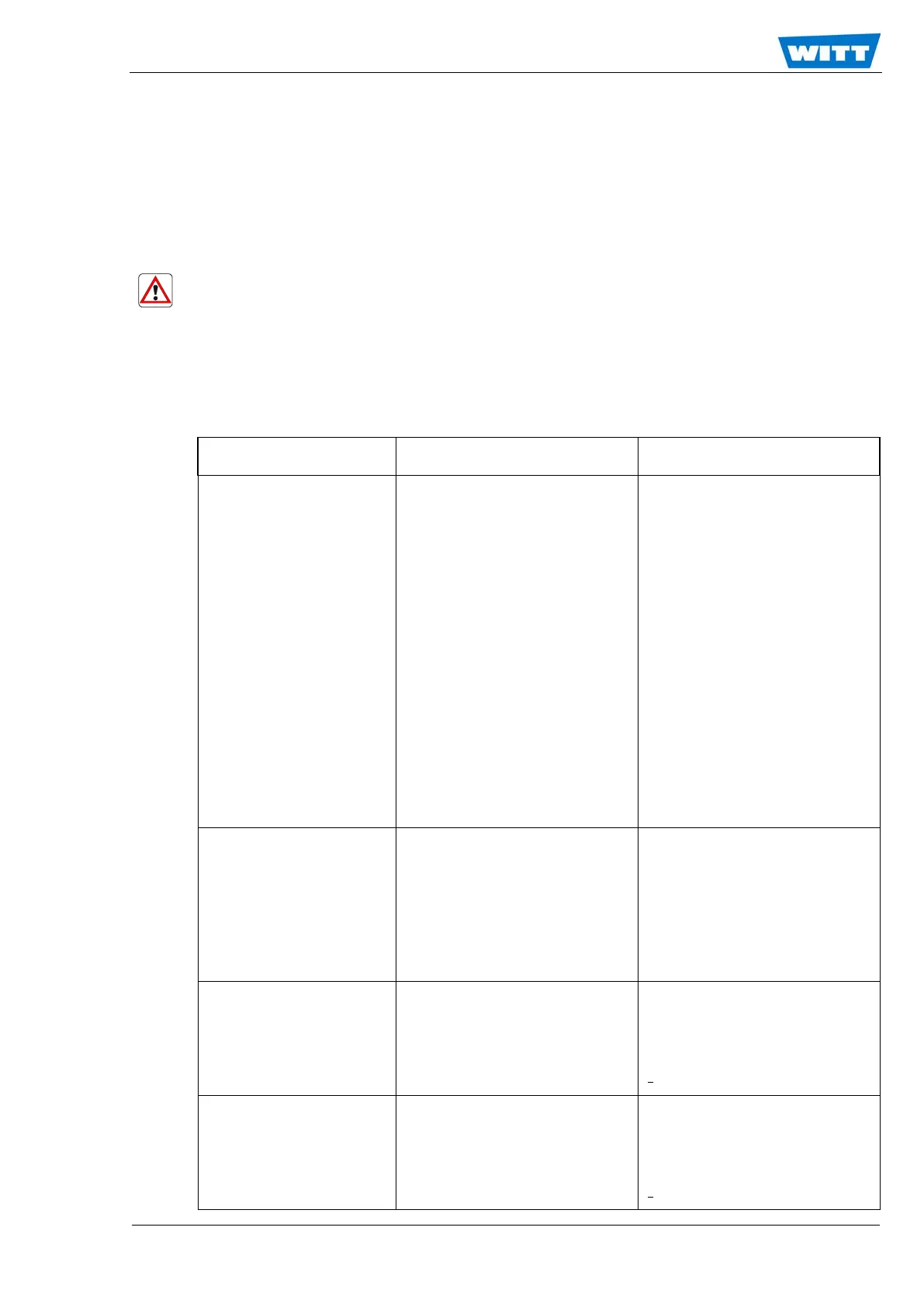

Malfunction Cause Remedy

•

The result of the anal-

ysis does not match

with the expected val-

ues

•

The concentration is not as it

was expected

•

Wrong measuring gas / carri-

er gas combination in MGM

selected

•

Analyser not correctly cali-

brated

•

Calibration gas settings at the

analyser module does not

match with the calibration gas

concentrations

•

Inlet filter clogged

•

Instrument internally contam-

inated by liquid

•

Change composition of the

gas mixture

•

Select adequate measuring

gas / carrier gas combination

for the analysis gas

•

Calibrate analyser

(Section 6.3 and 7.3)

•

Adjust the setting for calibra-

tion gas concentrations

(Section 7.3.1 and 7.3.2)

•

Replace filter

•

Contact

WITT-GASETECHNIK,

have analyser checked

•

After switching power

on, the display is not

illuminated

•

Instrument is not connected

to main power supply

•

Defective fuse

•

Check connection to mains

and rectify, as applicable

•

Check and replace fuse if

necessary. If the fuse is de-

fective immediately after re-

placing contact

WITT-GASETECHNIK,

•

Min. concentration

alarm

•

Concentration falls below

lower threshold limit of the

respective gas

•

Check adjustment of gas

mixer

•

Check gas supply

•

Check threshold limit

•

Max. concentration

alarm

•

Upper threshold limit of the

respective gas is exceeded

•

Check adjustment of gas

mixer

•

Check gas supply

•

Check threshold limit

Loading...

Loading...