Page 22 of 46

WITT-GASETECHNIK GmbH & Co KG

Gas Safety- & Control Equipment

7.3.4 Gain Calibration

The gain calibration procedure is only accessible after offset calibration. This is due to the fact that

a gain calibration with an improper offset leads to erroneous indication of the instrument.

The procedure of the gain calibration is analogue to the offset calibration. If the operator wants to

abort the gain calibration choose “ESC” in any menu to get back to the starting point “Gain Calibra-

tion”. If the operator now choose “NO” he is prompt to apply process gas. The gain remains un-

changed. However the recently determined offset is applied.

7.4 Diagnosis

The instrument has built in diagnosis and test functions. If the instrument is in the “safe mode”, the

operator needs the so called “Operator Code” in order to get access to diagnosis functions. By de-

fault the operator code is set to “111.000”.

7.4.1 Parameter Menu

The entire accessible individual configuration of the MFA 9000 is stored in about 200 Parameters.

In the Parameter menu all configuration and actual measuring can be retrieved from the instru-

ment. This may help to diagnose malfunction and mal settings.

The parameter menu gives the operator the possibility to scroll through the whole parameter list of

the MFA 9000.

To scroll forward within the parameter list press ENTER. To scroll backwards press UP. The num-

ber of the parameter is shown in the last line.

To leave the parameter menu press RIGHT. If the OK is marked press ENTER.

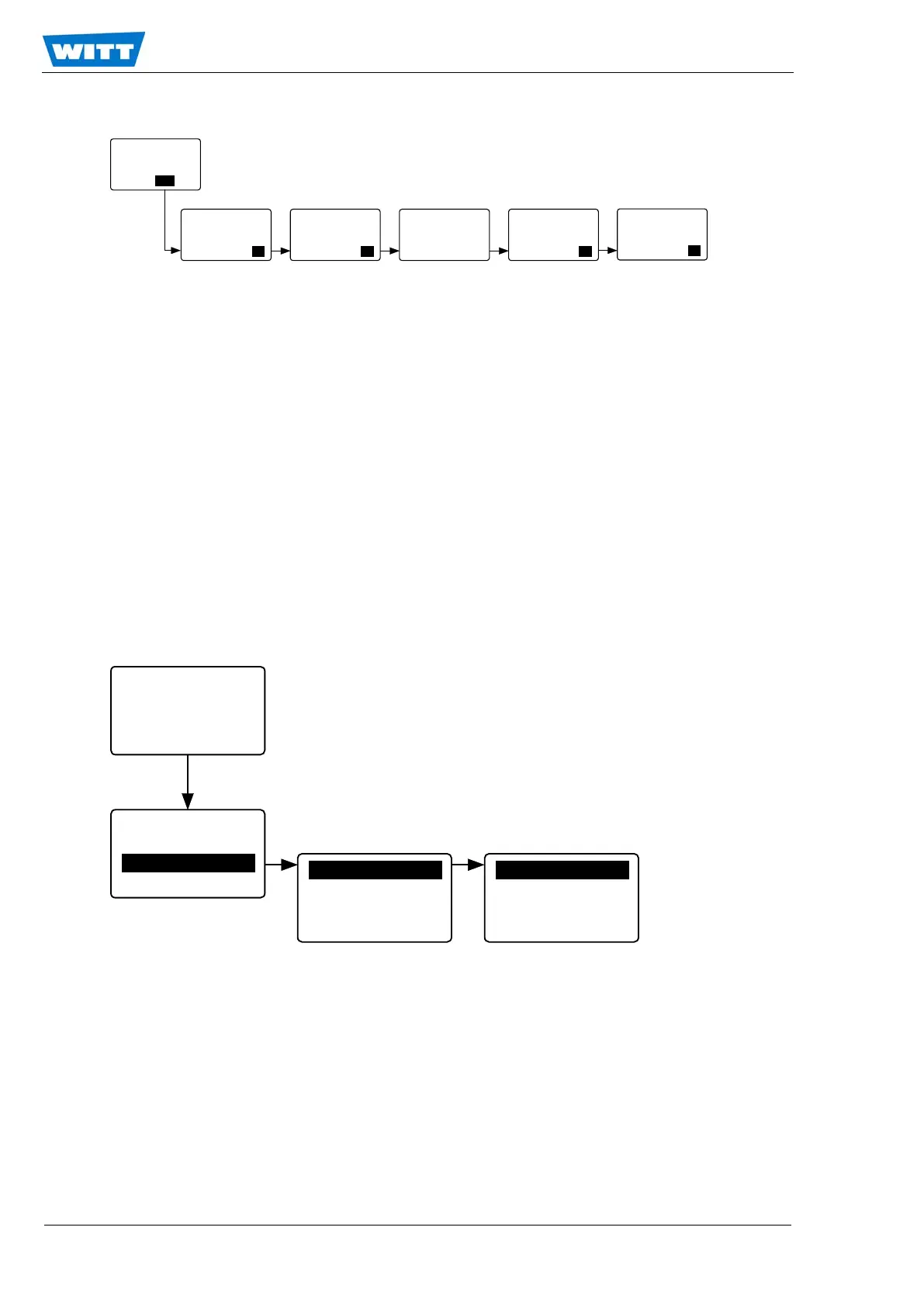

G

ain Calib.

Apply Gas

100.00

[%] ESC/OK

Stability

Targ. 100.00

Actu. 99.98

[%] ESC/OK

Sampling 10s

for Gain

Calibration

Please Wait

Save Calib.

Targ. 0.00

Actu. 0.00

[%] ESC/

OK

Gain

Calibration?

------------

YES/NO

Apply

Process Gas

Actu. 0.00

ESC/OK

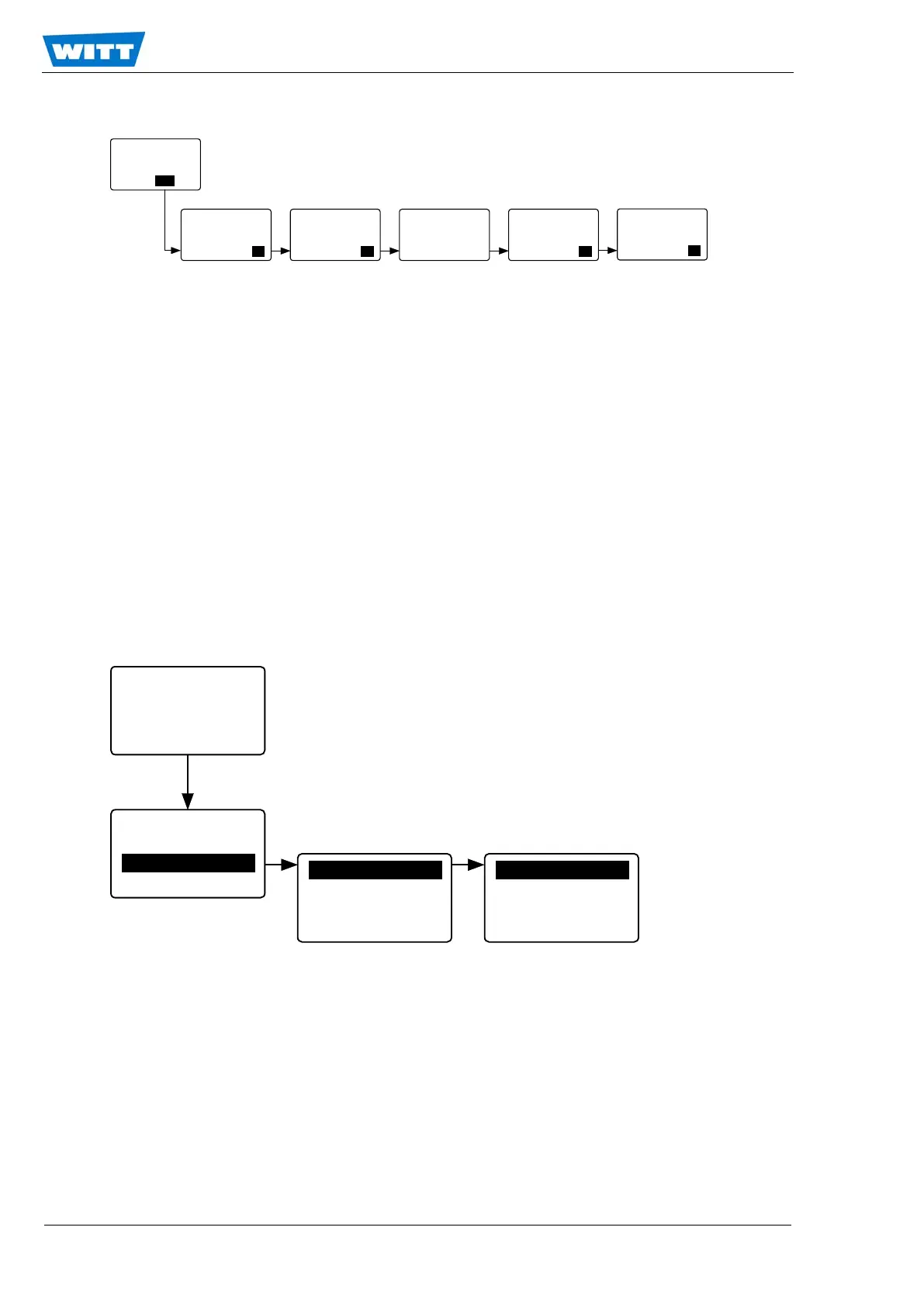

Operation

Calibration

Diagnosis

Setup

0.30

[%] H2/N2

Parameter

Errors

Compound Raw

set: 3000.00

------------

P001 OK

Loading...

Loading...