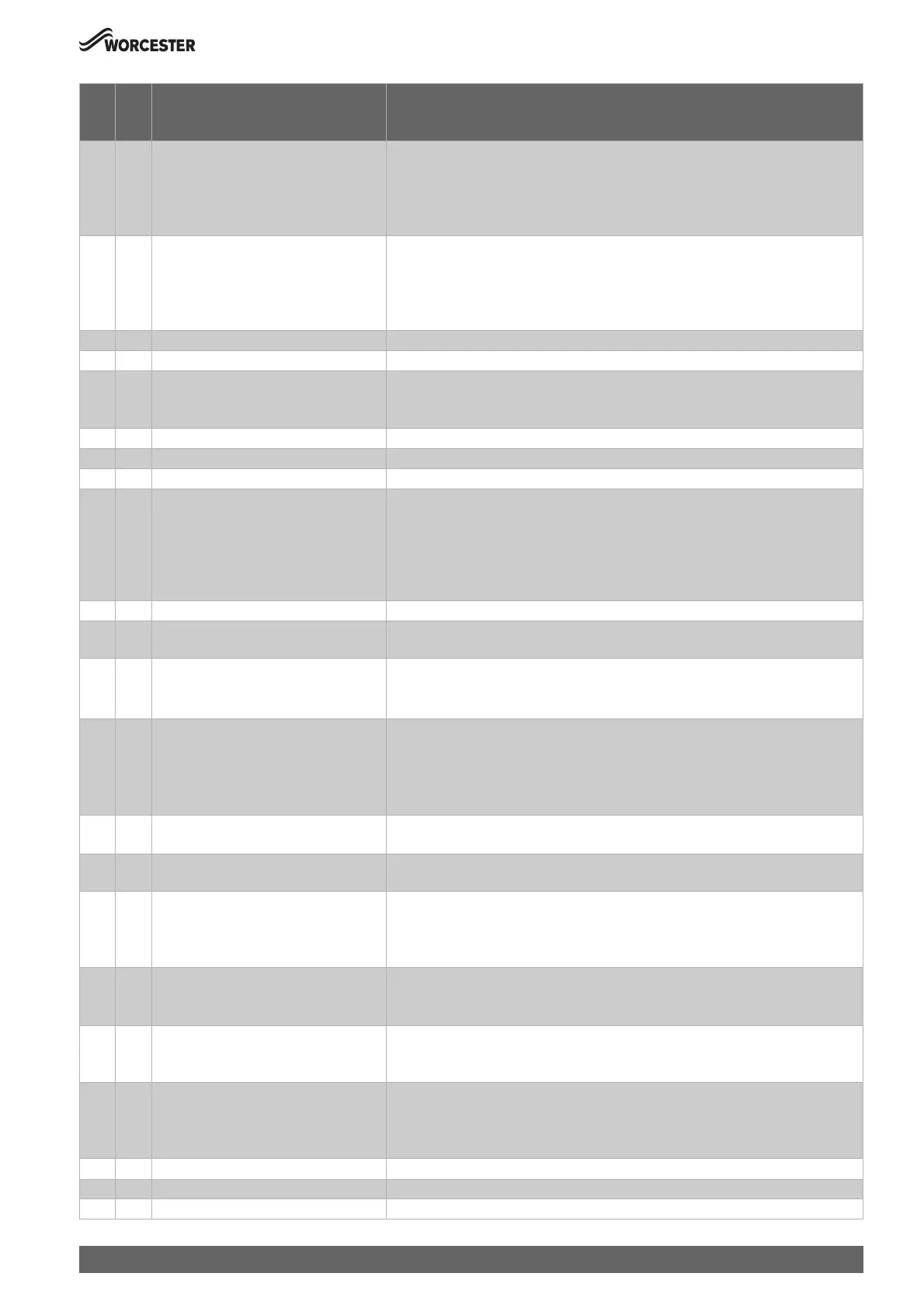

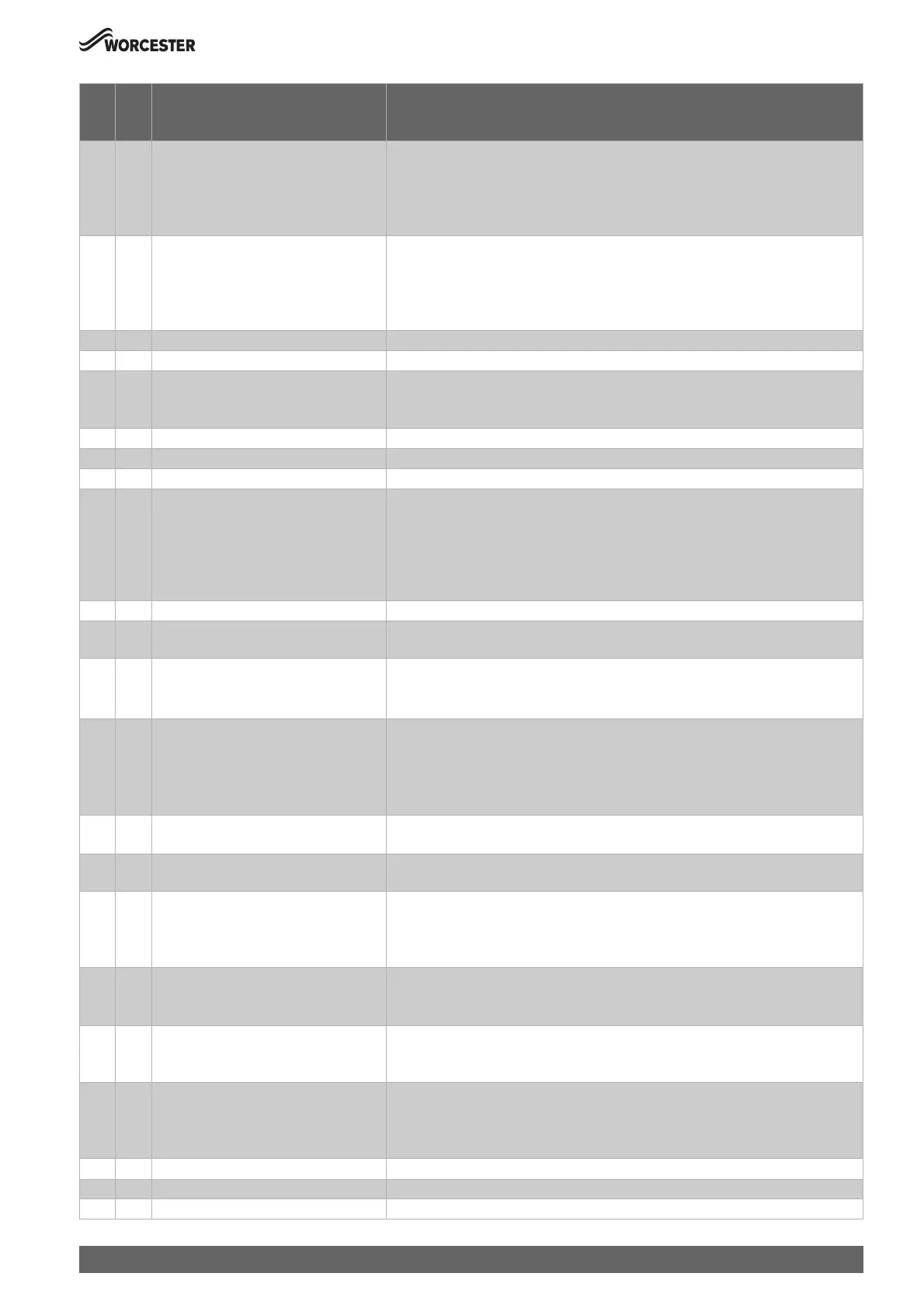

Fault finding and diagnosis

77

Greenstar 2000 – 6 721 820 552 (2021/02)

263 V Program sequence error ▶ Restart the appliance to see if the problem re-occurs.

▶ Check the electrical connections on the board (check for loose wires etc.).

▶ Check the code plug, if present, is not damaged.

▶ Replace the code plug, if present and required.

▶ Replace the control unit (PCB).

264 B Air handling failed during operation ▶ Reconnect the fan plug properly, perform reset.

▶Replace fan.

▶ Mains voltage must correspond to the default value.

▶ Remove any blockages in the flue system.

▶ Check venturi/injector for potential blockage.

265 O Heat demand lower than energy supplied Operating message, is not a fault.

268 O Relay test was activated Operating message, is not a fault.

269 V Flame monitoring ▶ Restart the appliance to see if the problem re-occurs.

▶ Check the electrical connections on the board (check for loose wires etc.).

▶ Replace the control unit (PCB).

270 O Starting up boiler Operating message, is not a fault.

273 O Operation of burner and fan interrupted Operating message, is not a fault.

275 O Boiler electronics in test mode Operating message, is not a fault.

281 B Pump pressure increase too low ▶ Check the flow pressure in system.

▶ Check the system for circulation issues (air locks, blockage, restriction).

▶ Check that the tacho/PWM plug, if present, for the circulation pump is fitted correctly.

▶ Check the tacho/PWM cable, if present, for continuity and replace the tacho/PWM cable

if required.

▶ Replace the pump.

283 O Burner starting Operating message, is not a fault.

284 O Opening air/gas ratio control valve/oil

solenoid valves

Operating message, is not a fault.

305 O Boiler in hot water anti-cycle mode Anti-fast cycle mode, domestic hot water keep warm function.

▶ Diverter valve is held in the hot water position for a period of time.

▶ Check for false demands on the cold water inlet.

306 V Flame signal after closing the fuel supply Tip: Ensure the working pressure returns immediately to the standing pressure when the

gas valve closes.

▶ Check the gas supply to the property and the inlet on the gas valve (check drop on inlet).

▶ Check the gas valve is not passing and replace if required.

▶ Replace the PCB.

323 – BUS signal cannot be processed ▶ Check connection to EMS controls, including 2-core cable if hard-wired.

▶ Check and replace PCB.

328 V Brief mains voltage failure ▶ Check for voltage interruption between electrical wiring system of the building and the

appliance.

341 B Temperature rise at boiler too rapid ▶ Open isolation valves.

▶ Connect plug to pump.

▶Replace pump.

▶ Ensure circulating pump is set on Constant speed mode - curve III.

342 B Temperature rise during hot water mode too

rapid

▶ If the water pressure is too low, top up with water and vent the system.

▶ Ensure isolation valves are open

▶ Check and replace diverter valve

350 B Short-circuit at flow temp. sensor ▶ Check and replace flow temperature sensor and harness Section 13.2.

▶ Check and replace the connecting lead to the flow temperature sensor.

▶ Check and replace control unit/burner control unit.

351 B Flow temp. sensor interrupted ▶ Connect the plug to the flow temperature sensor.

▶ Check and replace flow temperature sensor and harness Section 13.2.

▶ Check and replace the connecting lead to the flow temperature sensor.

▶ Check and replace control unit/burner control unit.

353 – Test non-volatile lockout Device may not start temporarily, never been off for 20 min for 24 h.

354 – Test volatile lockout Overpressure setting is detected.

356 B Power supply for the boiler is too low ▶ Establish supply voltage of at least 196 VAC.

Fault

code

Fault

category

Description Remedy

Loading...

Loading...