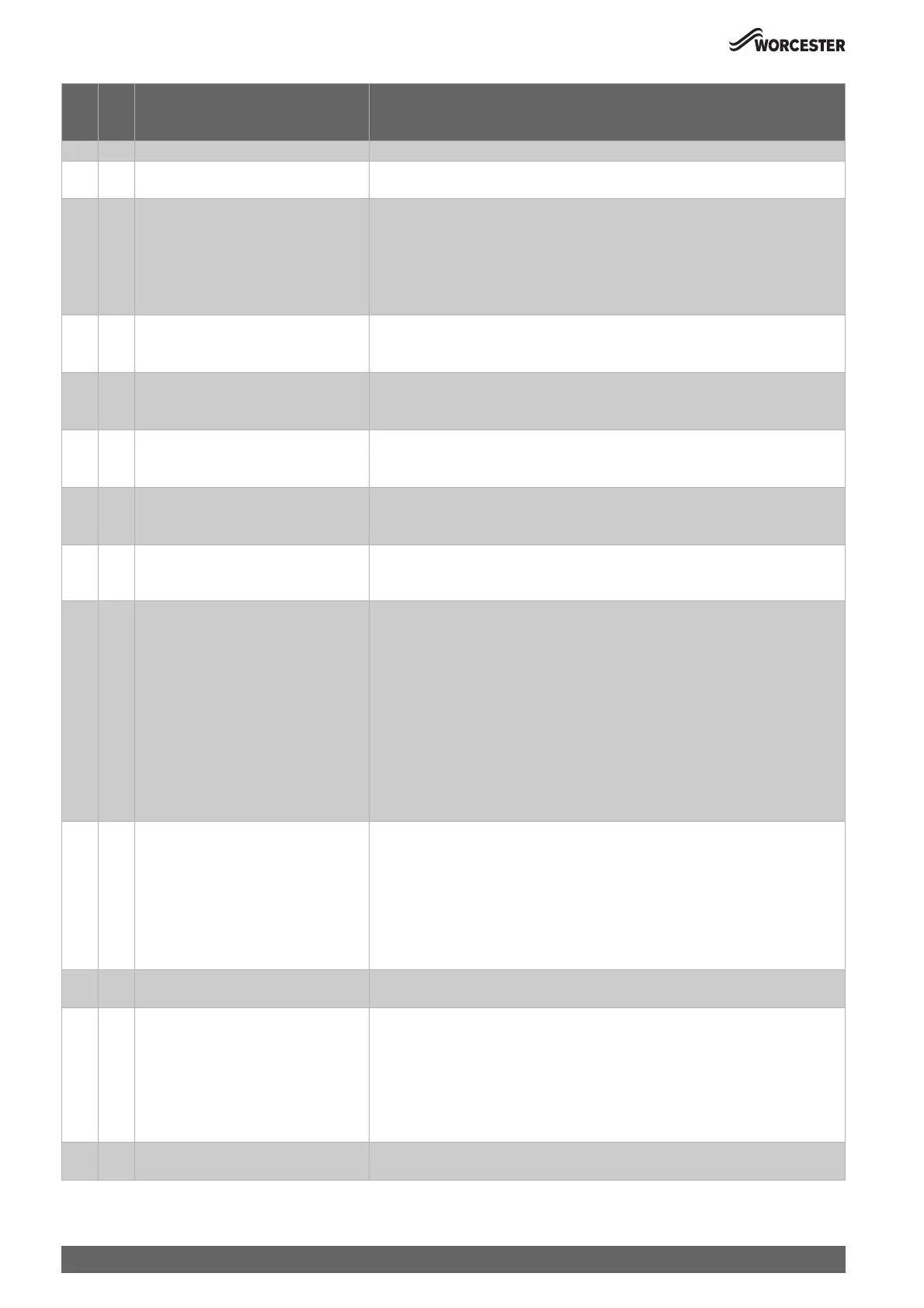

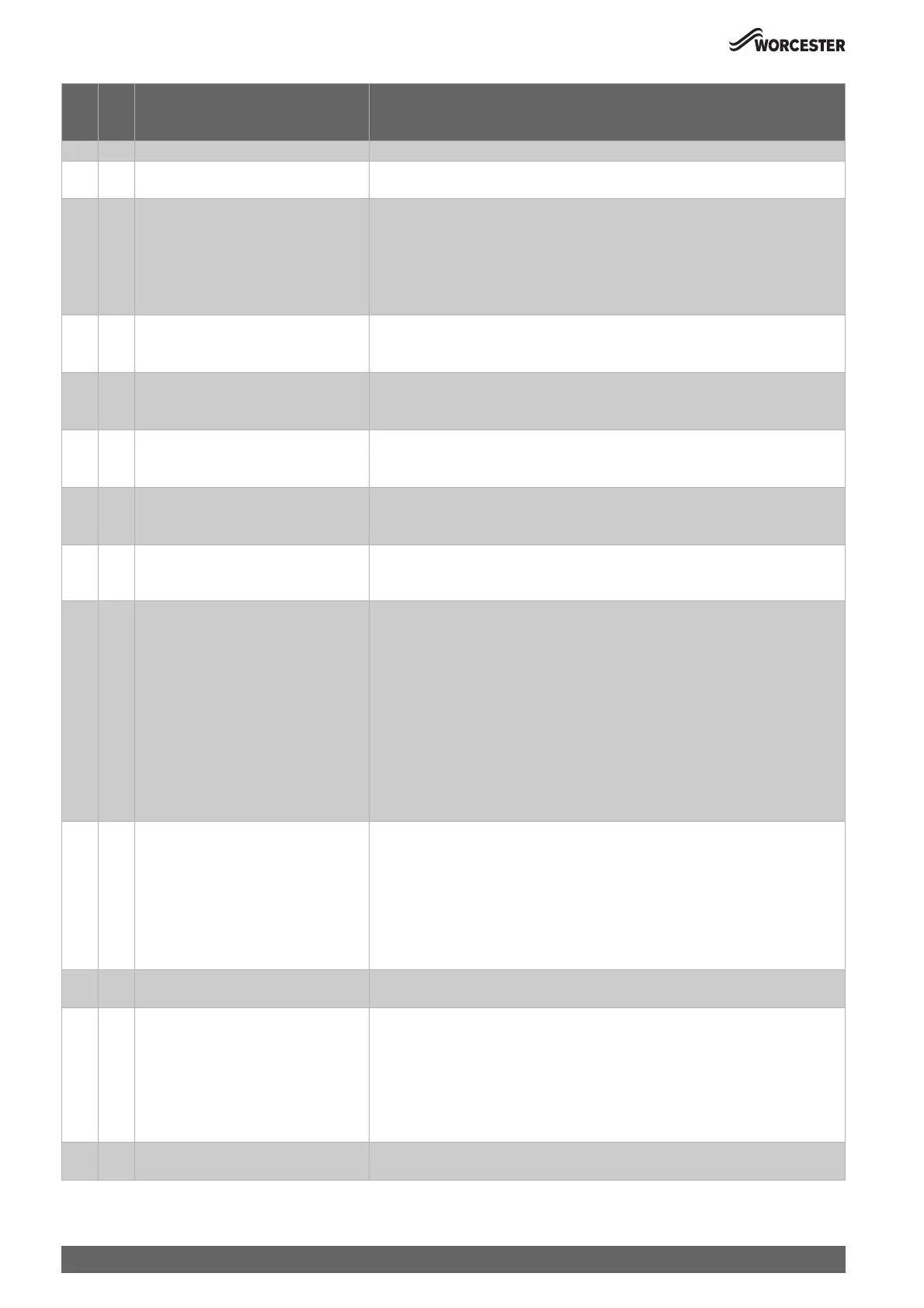

Fault finding and diagnosis

Greenstar 2000 – 6 721 820 552 (2021/02)

78

357 O Ventilation program Operating message, is not a fault: Venting program has been activated.

358 O Anti-seizing functn. active Operating message, is not a fault: blocking protection for the heating pump and the 3-way

valve is active.

360 V Incomparable code plug If code plug is present:

▶ Check that correct plug is inserted.

▶ Check the code plug is not damaged.

▶ Replace the code plug if required.

If code plug is not present:

▶ Check appliance electronics (PCB), replace if necessary.

362 V Boiler identification module or boiler

electronics faulty

▶ Wrong code plug is inserted.

▶ Check the code plug is not damaged.

▶ Replace the code plug if required.

363 V Ionisation current did not drop during

ionisation test

▶ Check and replace the ionisation cable.

▶ Check and replace the electrodes if required.

▶ Check and replace the control unit and/or burner control unit.

364 V Solenoid valve ev2 leaking. ▶ Check the gas valve, replace if required.

▶ Check electrodes and connecting leads, replace if required.

▶ Check and replace the appliance electronics.

365 V Solenoid valve ev1 leaking. ▶ Check the gas valve, replace if required.

▶ Check electrodes and connecting leads, replace if required.

▶ Check and replace the appliance electronics.

604 V System fault burner control unit ▶ Reset appliance - factory reset.

▶ If the fault persists following a reset, the burner control unit/PCB is faulty and must be

replaced.

810 – Hot water remains cold ▶ Prevent water from escaping.

▶ Position DHW temperature sensor correctly.

▶ If current is not being supplied to the 3-way valve, there is a problem in the cable

between the control panel and valve. Check screw terminals and cables.

▶ If current is being supplied to the 3-way valve but it is still not working, the valve is faulty

and must be replaced.

▶ If a voltage of approx. 230 V is measured at the terminals and the pump is not running,

the pump is faulty and must be replaced.

▶ Eliminate all faults in the cables. Vent if necessary.

▶ Replace the pump if there are any deviations whatsoever.

▶ Set the DHW heating to “Priority”.

▶ If readings are different to the values in the table, replace the sensor.

1010 O No BUS communication ▶ Check the HMI for display and remove the HMI and the test voltage to the HMI.

▶ Check the HMI plug on far right of the PCB (low voltage connection).

▶ If using the Key: Check the Key connections (black, white, red, green) are plugged in to

the correct position on the PCB. (Next to orange BUS connection leaving one space.)

Check the pins on the plug.

▶ Check the bridging links are in LR & 230 V out.

▶ Replace the board.

▶ Check the 230 V external wiring does not run alongside the BUS connections.

1013 R Max. combustion point reached ▶ Check the maintenance menu.

▶ Reset the maintenance code via the reset menu.

1014 W Actual ionisation is too low Tip: Check the ceramic insulator is not damaged, this can cause the spark to earth, twist

and pull the ceramic insulator to ensure it is not broken.

▶ Check the flame sense and the lead and replace if required.

▶ Check the earth tags on the boiler and on the electrodes.

▶ Check the operation of the siphon and no water collecting in the sump.

▶ Replace the air and/or gas ratio control valve.

▶ Replace the control unit and/or burner control unit.

1018 W Maintenance interval expired ▶ Check the maintenance date set in the menu.

▶ Reset the maintenance code via the reset menu.

Fault

code

Fault

category

Description Remedy

Loading...

Loading...