5-40

POWR

E

CRANKCASE, CRANKSHAFT ASSY., AND CYLINDER

BODY

Big-end oil clearance

1. Measure:

● Big-end oil clearance

Out of specification → Replace the

bearings as a set.

Big-end oil clearance:

0.020 ~ 0.052 mm

(0.0008 ~ 0.0020 in)

Measuring steps:

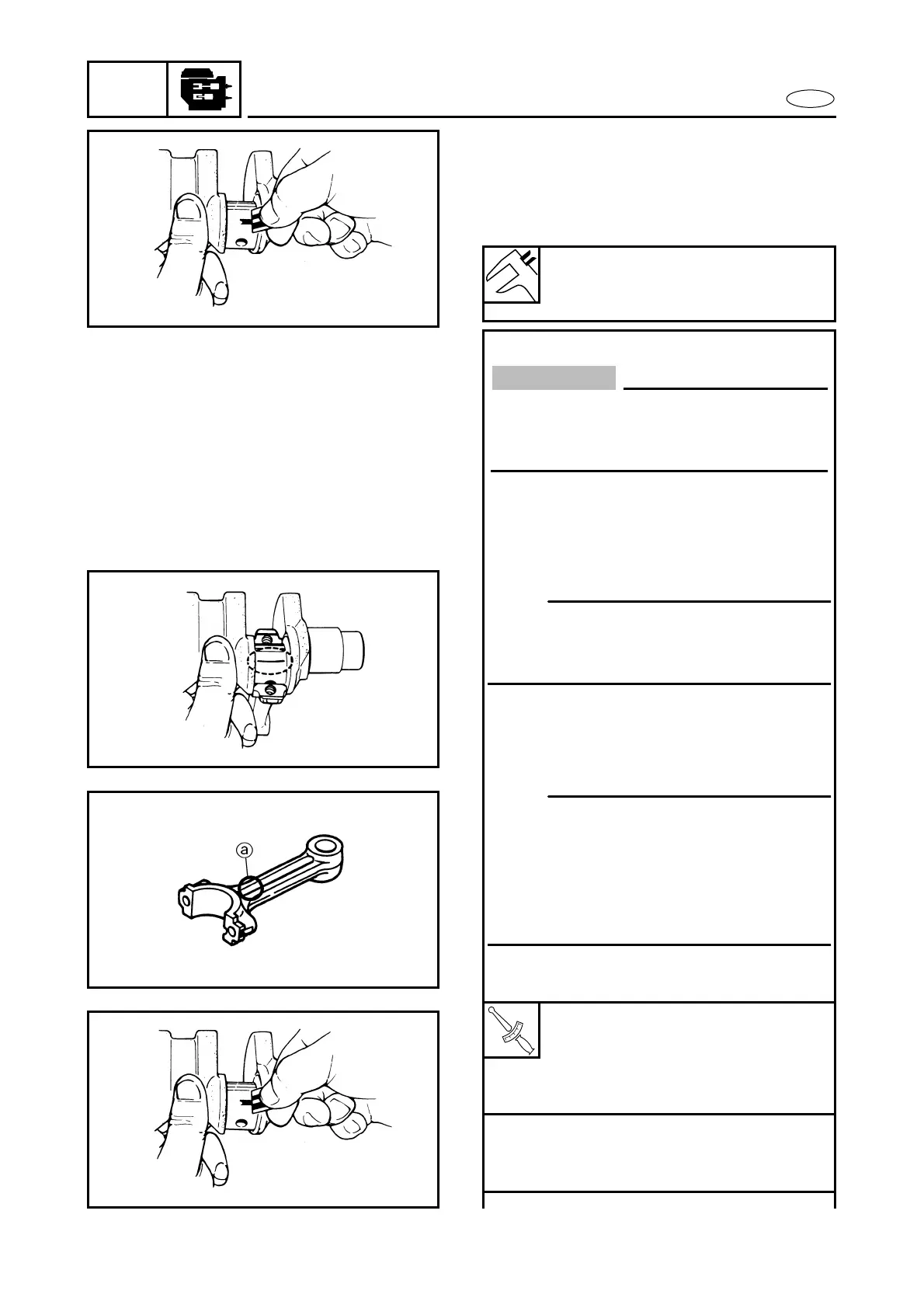

● Clean the bearings and bearing por-

tions of the connecting rod.

● Install the upper half of the bearing

into the connecting rod and the lower

half into the connecting rod cap.

● Put a piece of Plastigauge

onto the

crank pin.

● Assemble the connecting rod halves

onto the crank pin.

● Tighten the bolts in the proper

sequence and in two stages.

T

R

.

.

Bolt:

1st: 6.0 Nm

(0.6 m • kg, 4.4 ft • lb)

2nd: 16.5 Nm

(1.7 m • kg, 12.2 ft • lb)

● Remove the connecting rod cap.

● Measure the width of the compressed

Plastigauge

on each crank pin.

CAUTION:

Install the bearings in their original posi-

tions. Incorrect oil clearance measure-

ments can lead to engine damage.

NOTE:

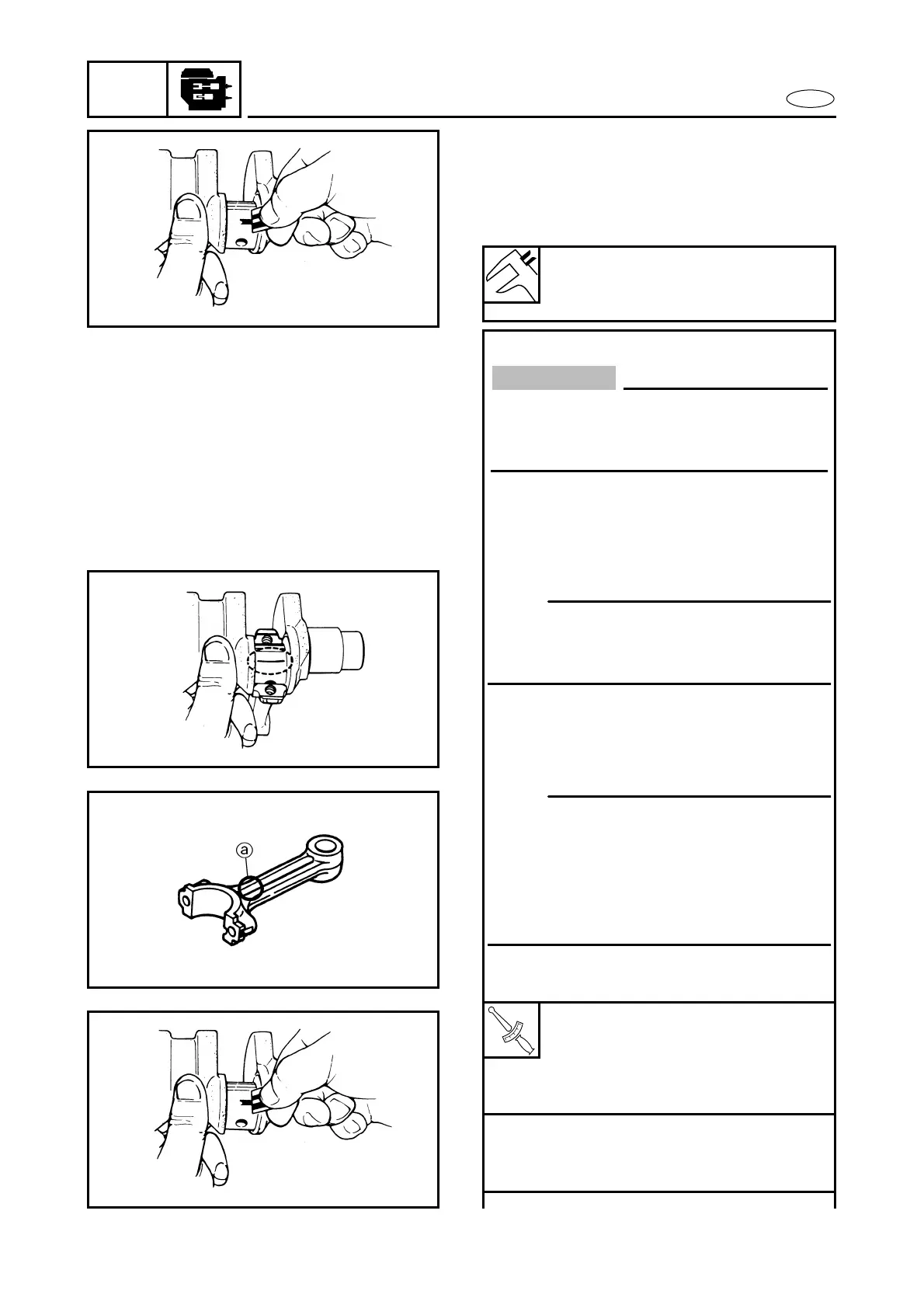

Align each bearing projection with the

notch in the connecting rod cap and con-

necting rod.

NOTE:

● Make sure the “Y” mark a on the con-

necting rod faces towards the flywheel

side of the crankshaft.

● Do not move the crankshaft until the big-

end oil clearance measurement has been

completed.

Loading...

Loading...