5.4 Operating Using Position Control with Pulse Train Reference

5-41

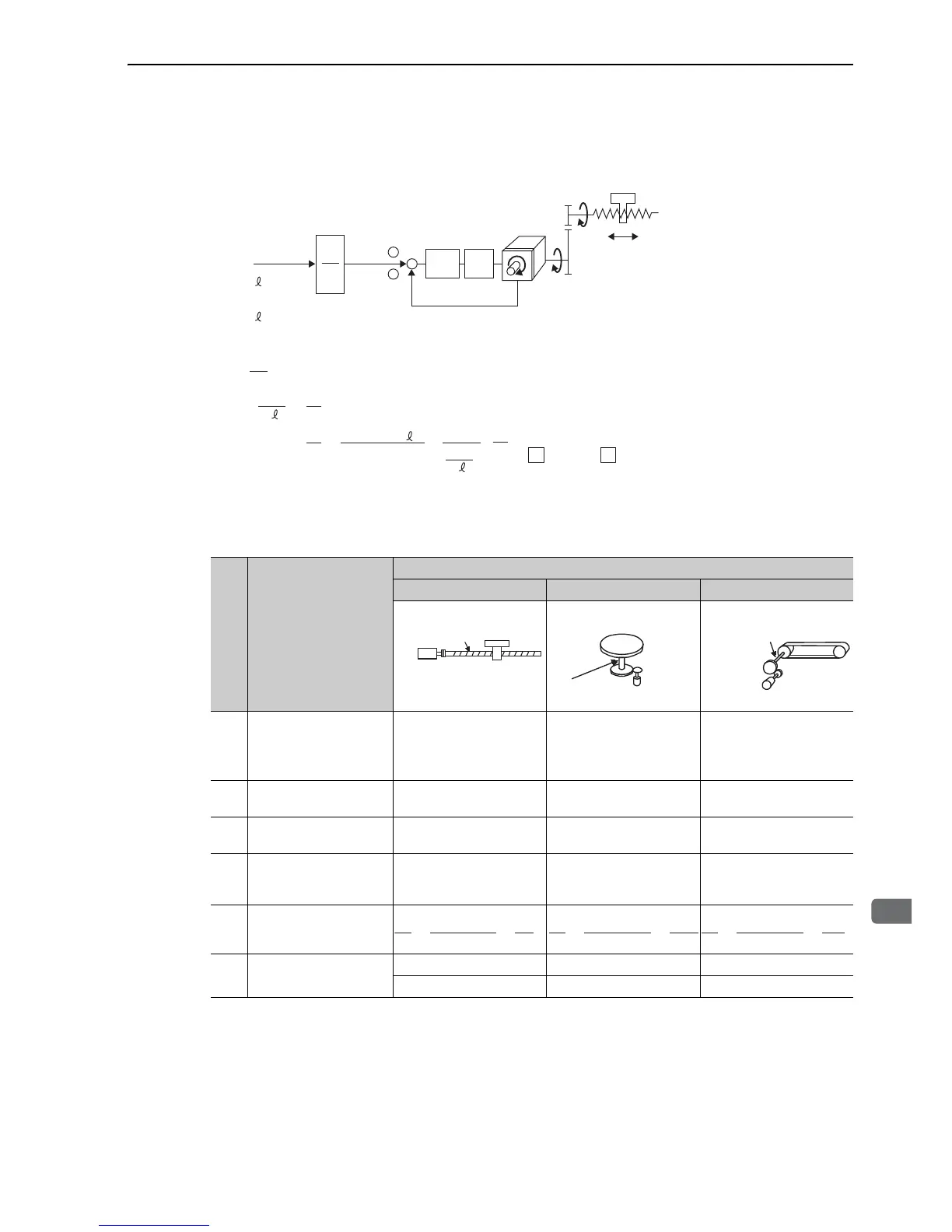

(3) Electronic Gear Ratio Equation

Refer to the following equation to determine the electric gear ratio.

(4) Electronic Gear Ratio Setting Examples

The following examples show electronic gear ratio settings for different load configurations.

A

B

m

n

+

−

Pitch = P (mm/rev)

m

n

Servomotor

P

G

P/rev

P

G

P/revޓ㧦Encoder resolution

Position

loop

Speed

loop

Reference pulse

Δ

n × P

n × P

B

Δ

A

Δ

P

Δ

Δ

×

×

()

m

n

= P

G

× m

B

A

()

==

P

G

× m × P

G

Set A and B with the following parameters.

A

㧦Pn20E

B

㧦Pn210

P mm/rev㧦Ball screw pitch

: Gear ratio (m is the rotation of the motor and n is the rotation of the load shaft.)

mm/P 㧦Reference unit

mm/P

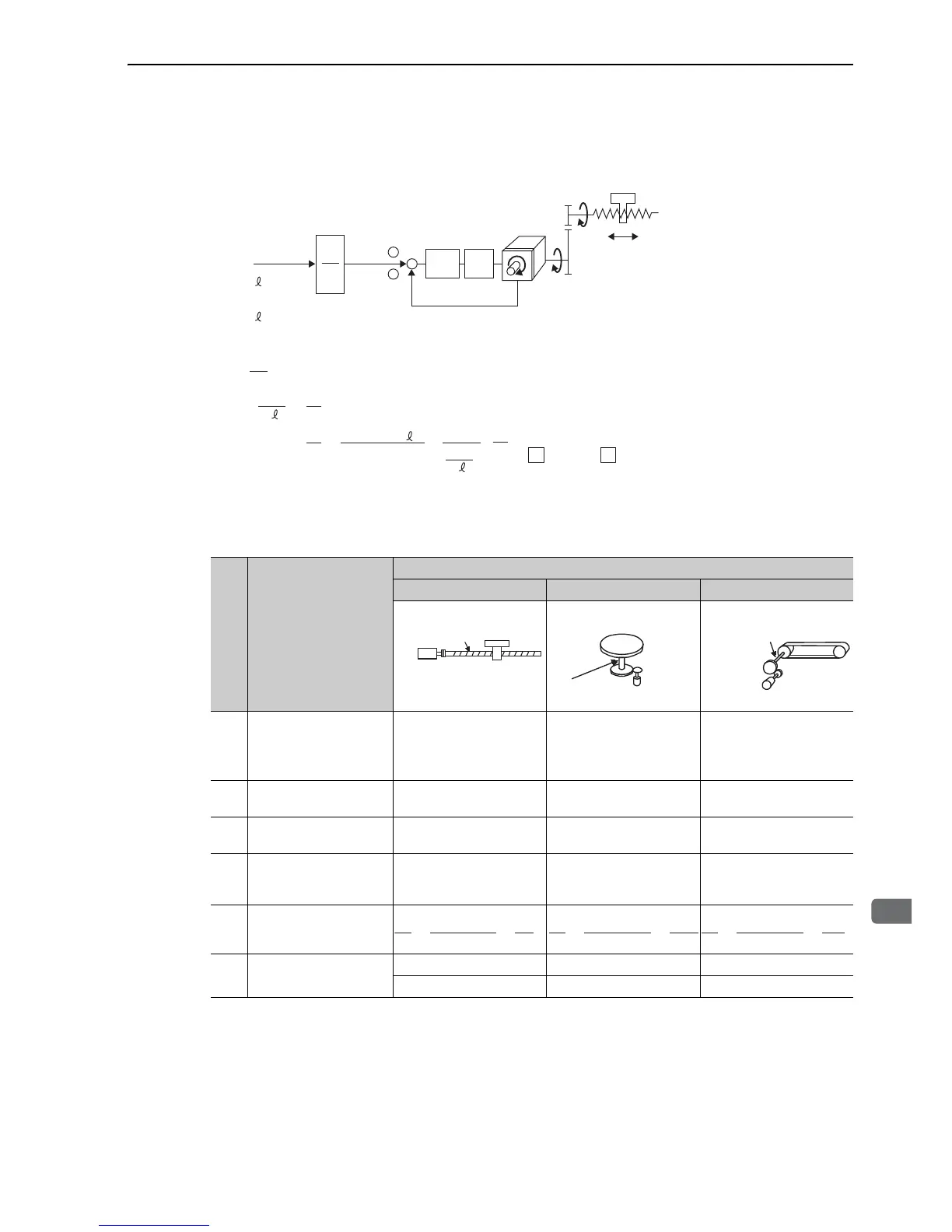

Step Operation

Load Configuration

Ball Screw Disc Table Belt and Pulley

1

Check machine specifica-

tions.

x Ball screw pitch: 6 mm

x Gear ratio: 1/1

Rotation angle per revolu-

tion: 360°

Gear ratio: 1/100

Pulley diameter: 100 mm

(pulley circumference: 314

mm)

• Gear ratio: 1/50

2

Check the encoder reso-

lution.

1048576 (20-bit) 1048576 (20-bit) 1048576 (20-bit)

3

Determine the reference

unit used.

Reference unit: 0.001 mm

(1 μm)

Reference unit: 0.01°

Reference unit: 0.005 mm

(5 μm)

4

Calculate the travel dis-

tance per load shaft revo-

lution.

6 mm/0.001 mm=6000 360°/0.01°=36000 314 mm/0.005 mm=62800

5

Calculate the electronic

gear ratio.

6 Set parameters.

Pn20E: 1048576 Pn20E: 104857600 Pn20E: 52428800

Pn210: 6000 Pn210: 36000 Pn210: 62800

Ball screw

pitch: 6 mm

20-bit encoder

Load shaft

Reference unit: 0.001 mm

20-bit encoder

Load shaft

Reference unit: 0.01°

Gear ratio:

1/100

Load shaft

Gear ratio

1/50

Reference unit: 0.005 mm

Pulley diameter:

100 mm

20-bit encoder

Loading...

Loading...