5-58

L: Protection Function Constants

The following settings are made with the protection function constants (L constants): Motor selection func-

tion, power loss ridethrough function, stall prevention function, frequency detection, torque limits, and hard-

ware protection.

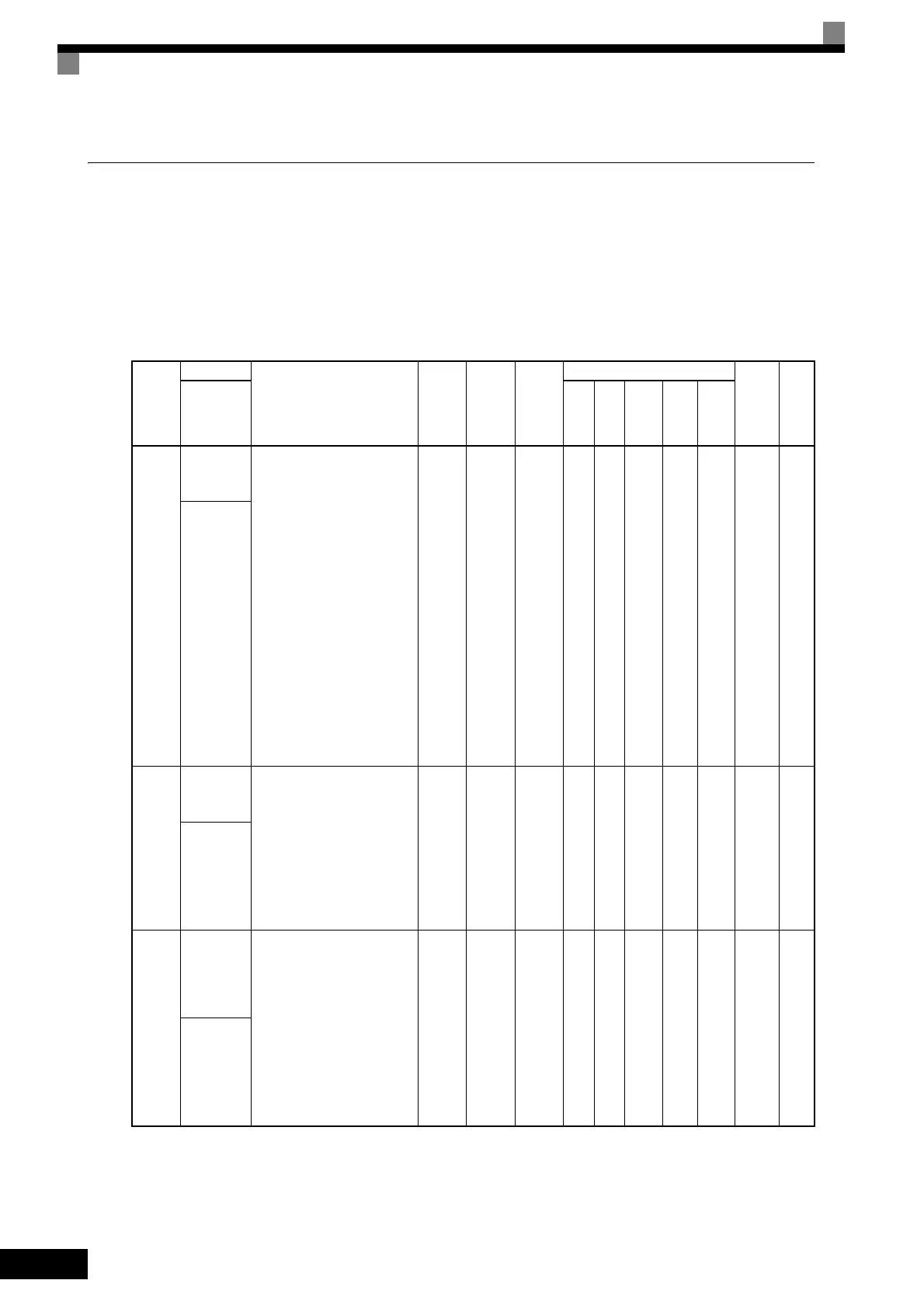

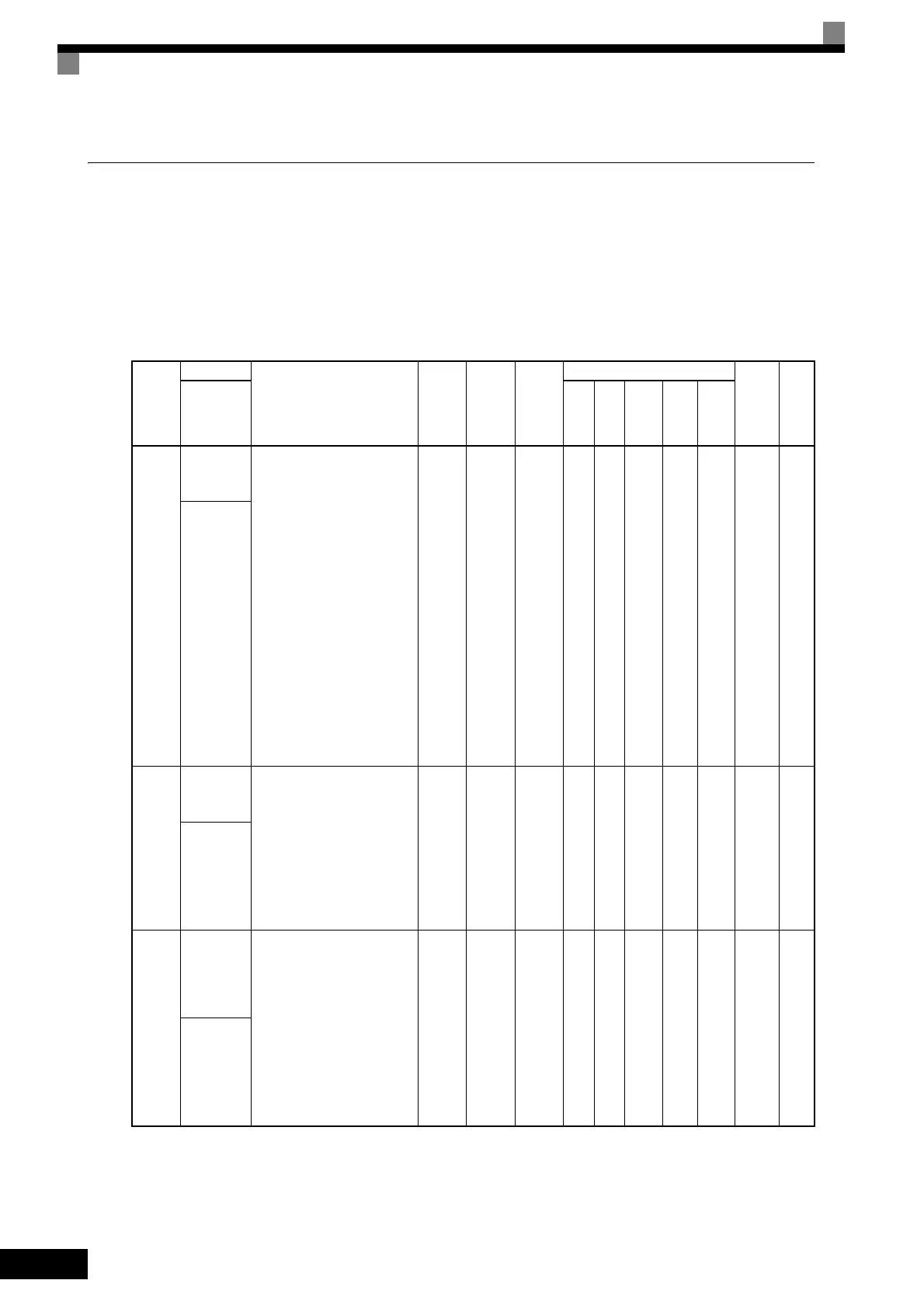

Motor Overload: L1

User constants for motor overloads are shown in the following table.

Con-

stant

Number

Name

Description

Setting

Range

Factory

Setting

Change

during

Opera-

tion

Control Methods

MEMO-

BUS

Regis-

ter

Page

Display

V/f

V/f

with

PG

Open

Loop

Vec-

tor

1

Flux

Vec-

tor

Open

Loop

Vec-

tor

2

L1-01

Motor pro-

tection

selection

Sets whether the motor over-

load function is enabled or dis-

abled at electric thermal

overload relay.

0: Disabled

1: General-purpose motor

protection

2: Inverter motor protection

3: Vector motor protection

In some applications when the

Inverter power supply is

turned off, the thermal value is

reset, so even if this constant is

set to 1, protection may not be

effective.

When several motors are con-

nected to one Inverter, set to 0

and ensure that each motor is

installed with a protection

device.

0 to 3 1 No Q Q Q Q Q 480H

4-5

6-57

MOL Fault

Select

L1-02

Motor pro-

tection time

constant

Sets the electric thermal detec-

tion time in seconds units.

Usually setting is not necessary.

The factory setting is 150%

overload for one minute.

When the motor's overload

resistance is known, also set the

overload resistance protection

time for when the motor is hot

started.

0.1 to

5.0

1.0 min No A A A A A 481H 6-57

MOL Time

Const

L1-03

Alarm oper-

ation selec-

tion during

motor over-

heating

Set H3-09 to E and select the

operation when the input motor

temperature (thermistor) input

exceeds the alarm detection

level (1.17 V).

0: Decelerate to stop using the

deceleration time in C1-02.

1: Coast to stop

2: Emergency stop using the

deceleration time in C1-09.

3: Continue operation (H3 on

the Operator flashes).

0 to 3 3 No A A A A A 482H 6-60

MOL Thm

Input

Loading...

Loading...