12 Operations

The transmitter makes available to the user some operations

that can be useful during the device life cycle.

These operations are supported and can be executed with the

DTM o EDD based configuration tools, or also by following the

instructions / descriptions below.

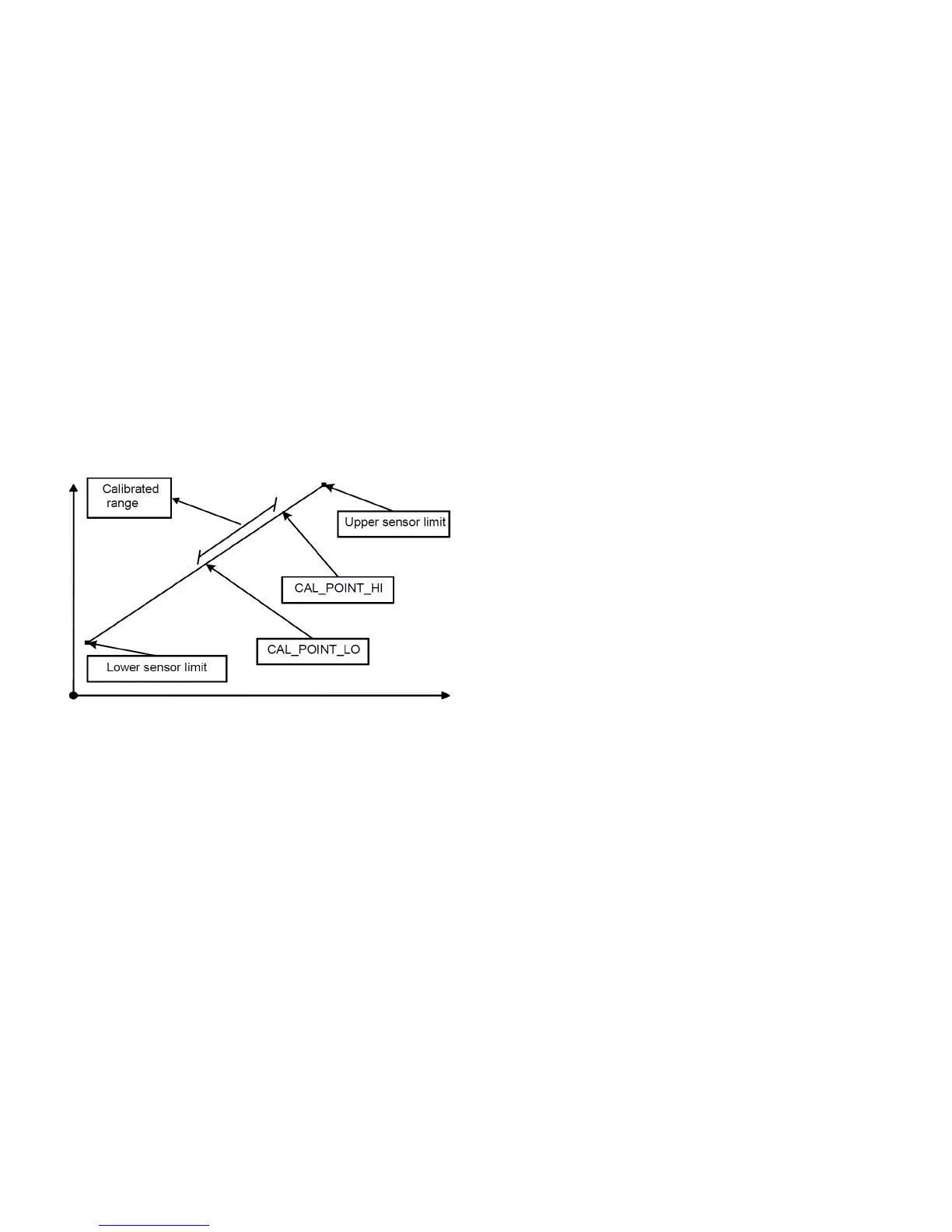

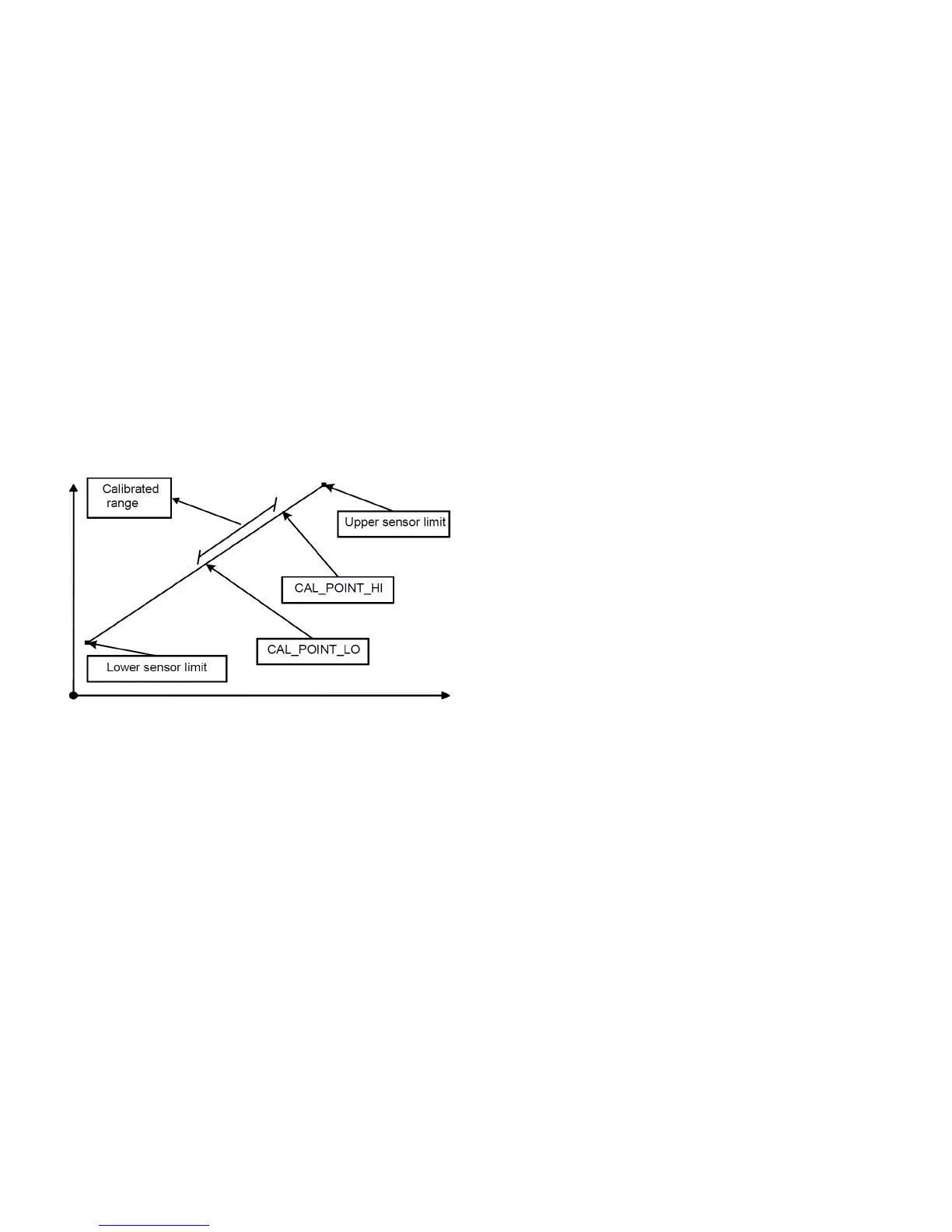

12.1 Sensor trimming / calibration

The scope of the sensor trimming / calibration is to adjust and

make accurate as much as possible the sensor conversion to a

pressure value in digital format.

The sensors of the 266 are calibrated/trimmed in the factory to

the customer‘s specified measuring range therefore it could be

necessary change or correct the sensor calibration later on as

maintenance operation. Two points are necessary to perform a

sensor calibration. Low sensor calibration point (Zero) writing in

PRTB_CAL_POINT_LO and High sensor calibration point

(Span) writing in PRTB_CAL_POINT_HI.

The minimum distance from the two points must be greater

than minimum span PRTB_CAL_MIN_SPAN.

Figure 44: Sensor Trimming / Calibration

12.1.1 P-dP sensor low trimming

With this operation the PRTB_TRIMMED_VALUE is

automatically adjusted, in order to match the real value of the

pressure applied in input, in the low part of the working range.

The following sequence of operations is required:

1. Apply a reference pressure in input using a reference

pressure generator.

2. Select the engineering unit of the measure in the

PRTB_SENSOR_UNIT (Pressure Unit Only)

3. Read the measure produced by the transmitter from the

PRTB_TRIMMED_VALUE.

4. If this value doesn’t match the pressure applied in input,

enter the correct known applied pressure value in the

PRTB_CAL_POINT_LO and write to the transmitter.

This writing executes an internal algorithm that produces the

new correction coefficients.

5. Read again the PRTB_TRIMMED_VALUE and check if its

value matches the applied pressure.

This operation can be executed also with the optional keypad

from the menu “Calibration/P-dP Sensor/Low Trimming”.

12.1.2 P-dP sensor high trimming

With this operation the PRTB_TRIMMED_VALUE is

automatically adjusted, in order to match the real value of the

pressure applied in input, in the high part of the working range.

The following sequence of operations is required:

1. Apply a reference pressure in input using a reference

pressure generator.

2. Select the engineering unit of the measure in the

PRTB_SENSOR_UNIT (Pressure Unit Only)

3. Read the measure produced by the transmitter from the

PRTB_TRIMMED_VALUE.

4. If this value doesn’t match the pressure applied in input,

enter the correct known applied pressure value in the

PRTB_CAL_POINT_HI and write to the transmitter.

This writing executes an internal algorithm that produces the

new correction coefficients.

5. Read again the PRTB_TRIMMED_VALUE and check if its

value matches the applied pressure

This operation can be executed also with the optional keypad

from the menu “Calibration/P-dP Sensor/High Trimming”.

12.1.3 Static pressure low trimming

With this operation the PRTB_STATIC_P_TRIM_VALUE is

automatically adjusted, in order to match the real value of

Static Pressure applied at the transducer in the lower part of

the range. The following sequence of operations is required:

1. Select the engineering unit of the measure in the PRTB_

STATIC_P_SENSOR_UNIT (Pressure Unit Only)

2. Read the Static Pressure value from the

PRTB_STATIC_P_TRIM_VALUE.

3. If this value doesn’t match the known Static Pressure

applied in input at the transducer, enter the correct value

in the PRTB_STATIC_P_CAL_POINT_LO and write to the

transmitter. This writing executes an internal algorithm

that produces the new correction coefficients.

4. Read again the PRTB_STATIC_P_TRIM_VALUE and

check if its value matches the real Static Pressure value.

12.1.4 Static pressure high trimming

(for piezo dP sensor only)

With this operation the PRTB_STATIC_P_TRIM_VALUE is

automatically adjusted, in order to match the real value of

Static Pressure applied at the transducer in the upper part of

the range. The following sequence of operations is required:

1. Select the engineering unit of the measure in the

PRTB_STATIC_P_SENSOR_UNIT (Pressure Unit Only)

2. Read the Static Pressure value from the

PRTB_STATIC_P_TRIM_VALUE.

3. If this value doesn’t match the known Static Pressure

applied in input at the transducer, enter the correct value

in the PRTB_STATIC_P_CAL_POINT_HI and write to the

transmitter. This writing executes an internal algorithm

that produces the new correction coefficients.

4. Read again the PRTB_STATIC_P_TRIM_VALUE and

check if its value matches the real Static Pressure value.

Loading...

Loading...