200 Actual signals and parameters

2606

SWITCHING FREQ

1, 4, 8, 12, 16 kHz - 4 kHz

Defines the switching frequency of the drive. Higher switching frequency results in

lower acoustic noise in the motor. See also parameter 2207 SWITCH FREQ CTRL

and section Switching frequency derating, I2N and ILD (= all currents) on page 387.

In multimotor systems, do not change the switching frequency from the default value.

2607

SWITCH FREQ

CTRL

1, 2 - 1

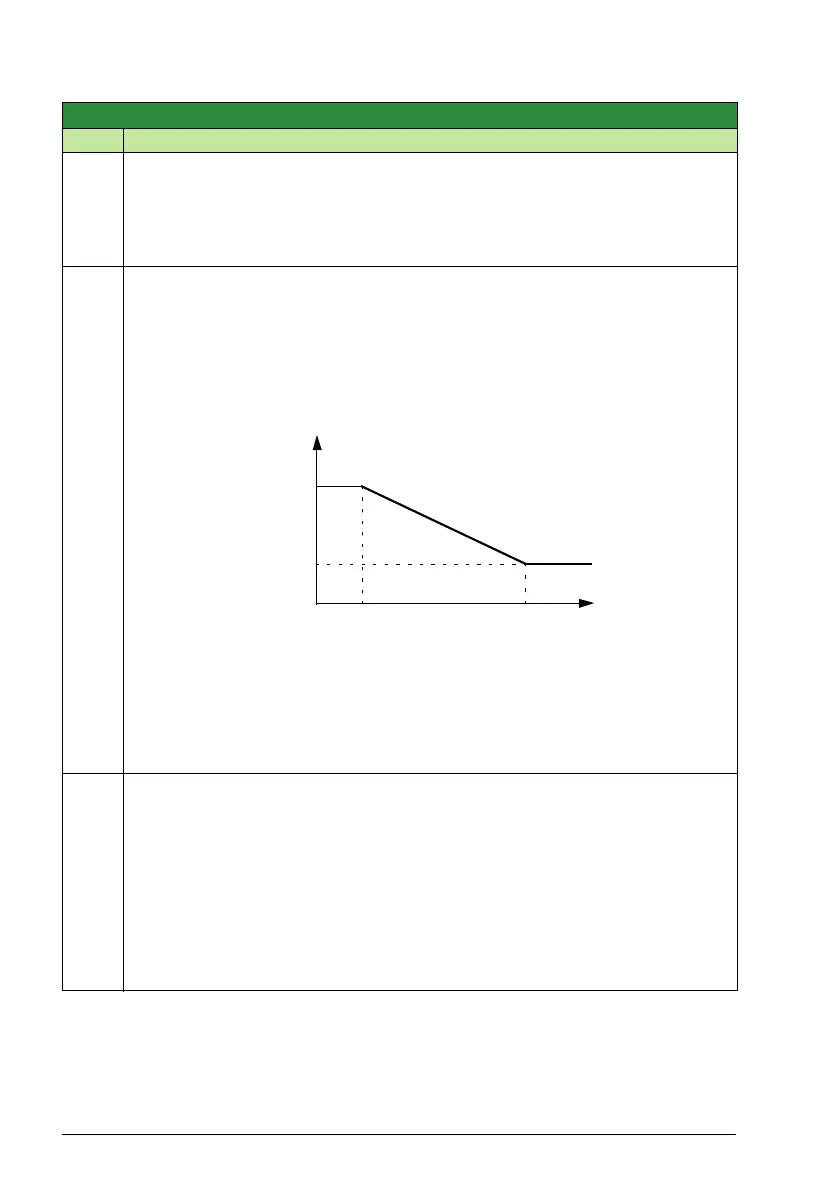

Activates the switching frequency control. When active, the selection of parameter

2606 SWITCHING FREQ is limited when the drive internal temperature increases.

See the figure below. This function allows the highest possible switching frequency at

a specific operation point.

Higher switching frequency results in lower acoustic noise in the motor, but higher

internal losses.

1 = ON – Active.

2 = ON (LOAD) – Switching frequency can adapt to loading instead of limiting the

output current. This allows maximum loading with all switching frequency

selections. The drive automatically decreases the actual switching frequency if

loading is too high for the selected switching frequency.

2608

SLIP COMP RATIO

0 … 200% 1 0

Defines the slip gain for the motor slip compensation control. 100% means full slip

compensation, 0% means no slip compensation. Other values can be used if a static

speed error is detected despite the full slip compensation.

Example: 35 Hz constant speed reference is given to the drive. Despite the full slip

compensation (SLIP COMP RATIO = 100%), a manual tachometer measurement

from the motor axis gives a speed value of 34 Hz. The static speed error is 35 Hz - 34

Hz = 1 Hz. To compensate the error, the slip gain should be increased.

0 = No slip compensation.

1…200 = Slip gain.

Group 26: Motor control

Code Description Range Resolution Default S

* Temperature depends on the drive output frequency.

16 kHz

4kHz

Drive

temperature

f

sw

limit

80…100 °C * 100…120 °C *

T

Loading...

Loading...