Actual signals and parameters 233

Analog input reference correction

Parameter values 9, 10, and 14…17 use the formula in the following table.

Where:

• C = Main Reference value (= COMM for values 9, 10 and = AI1 for values 14…17).

• B = Correcting reference (= AI1 for values 9, 10 and = AI2 for values 14…17).

Example:

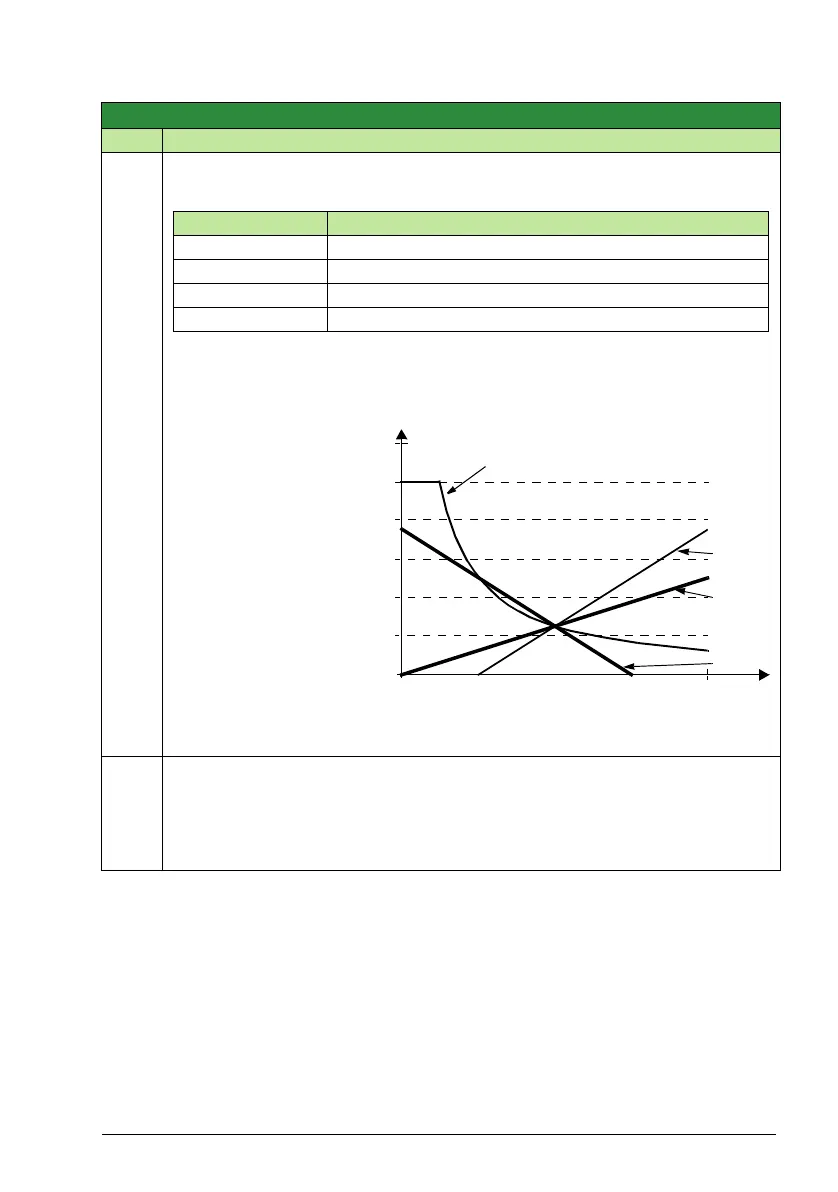

The figure shows the

reference source curves

for value settings 9, 10,

and 14…17, where:

•C = 25%.

• Parameter 4012

SETPOINT MIN = 0.

• Parameter 4013

SETPOINT MAX = 0.

• B varies along the

horizontal axis.

31 = DI4U, 5D(NC) – See

selection

DI3U,4D(NC).

32 = FREQ INPUT – Frequency limit.

4011

INTERNAL SETPNT

-3276.8 … 3277.7% 0.1% 40.0%

Selects a constant value as a process PID controller reference, when parameter 4010

SET POINT SEL value is set to INTERNAL.

• Unit and range depend on the unit and scale defined by parameters 4006 UNITS

and 4007 UNIT SCALE.

Group 40: Process PID set 1

Code Description Range Resolution Default S

Value Setting AI reference is calculated as following:

C + B C value + (B value - 50% of reference value)

C * B C value * (B value / 50% of reference value)

C - B (C value + 50% of reference value) - B value

C / B (C value * 50% of reference value) / B value

120

100

80

60

40

20

0

0

100%

9, 14 (+)

16 (-)

10, 15 (*)

17 (/)

B

Loading...

Loading...