118 Application macros

Torque control macro

This macro provides parameter settings for applications that require torque control of

the motor. Control can also be switched to speed control using a digital input. To

enable the macro, set the value of parameter 9902 APPLIC MACRO to 8 (TORQUE

CTRL).

For the parameter default values, see section Default values with different macros on

page 176. If you use other than the default connections presented below, see section

I/O terminals on page 51.

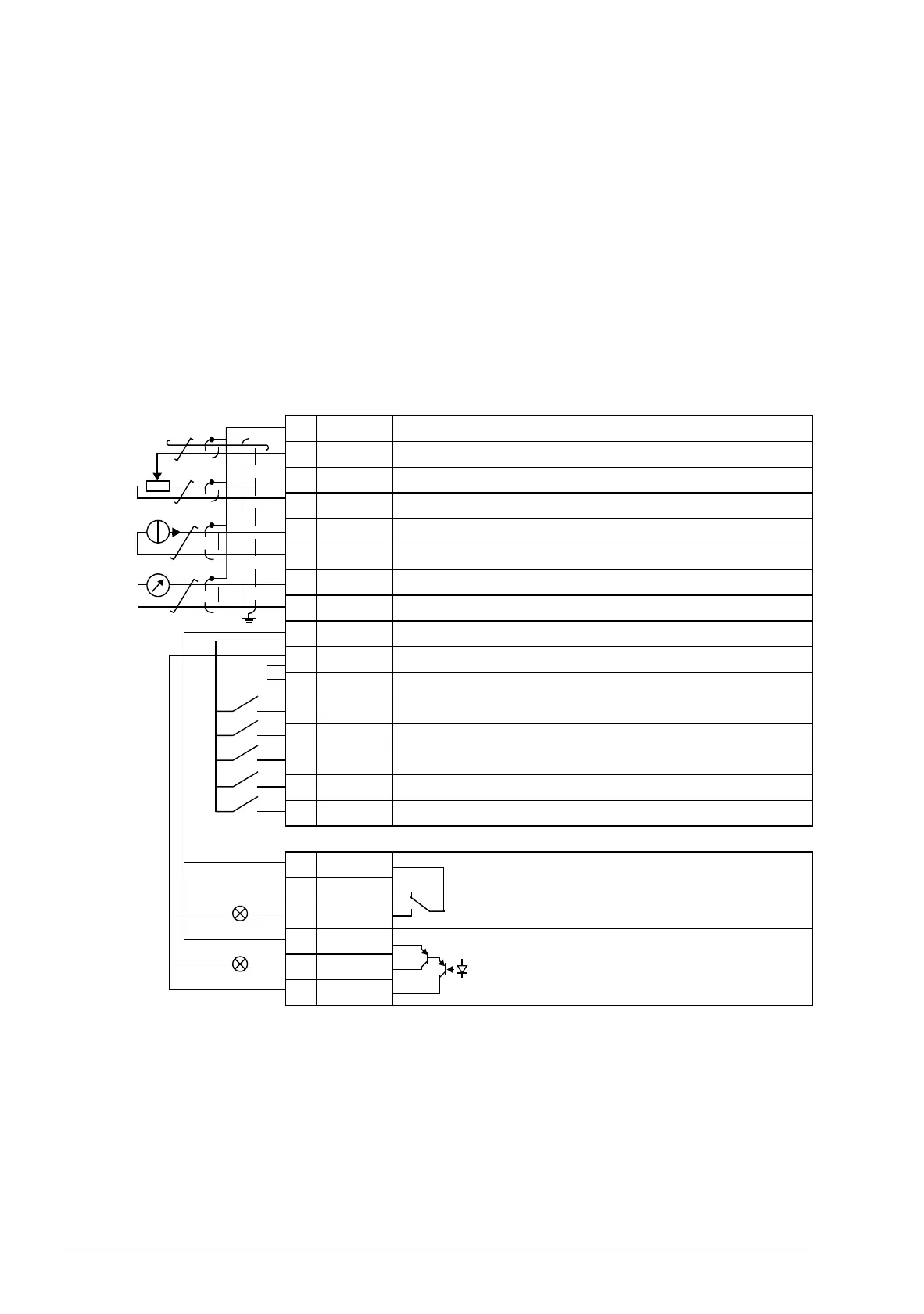

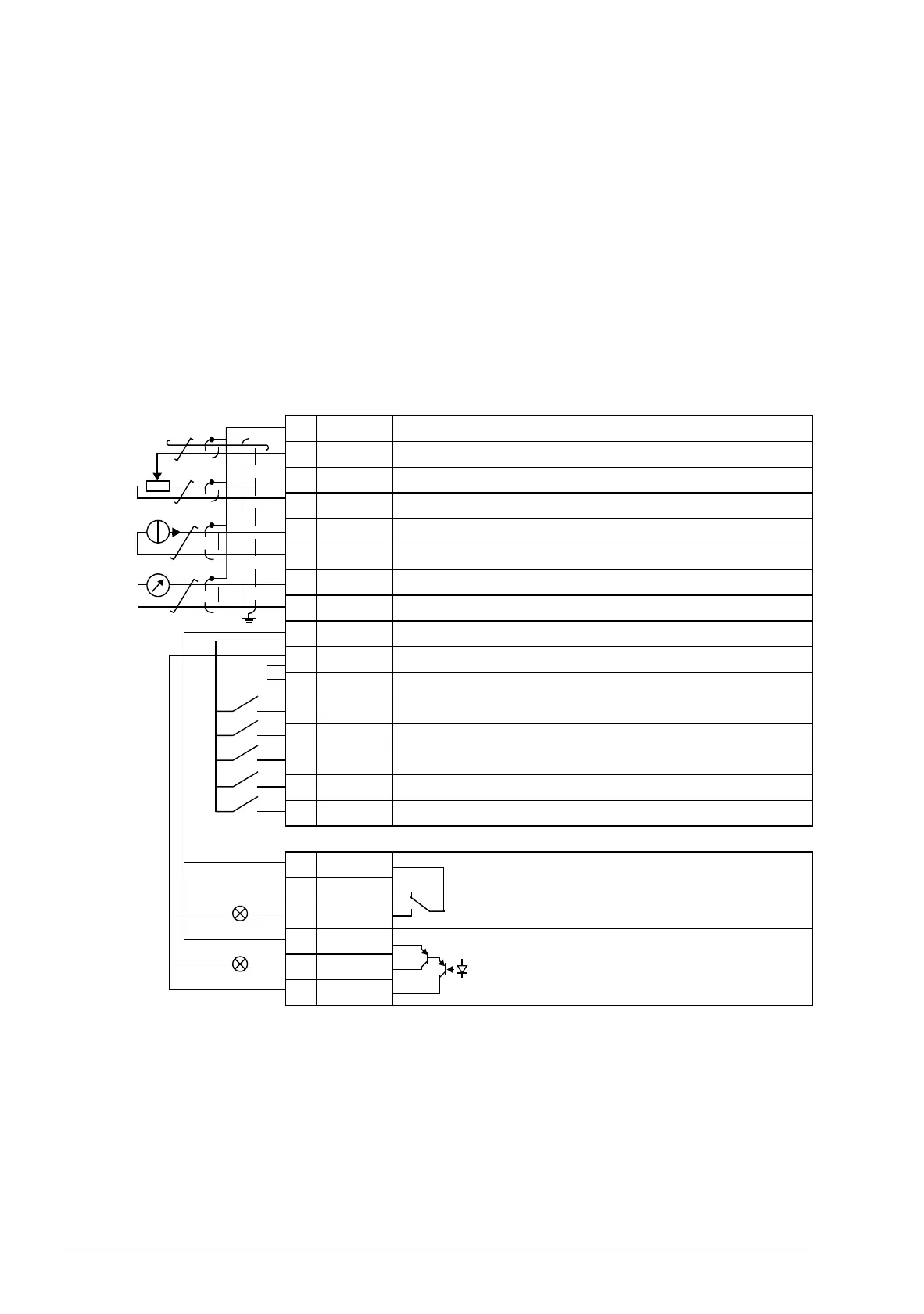

Default I/O connections

X1A

1 SCR Signal cable shield (screen)

2AI1 Motor speed reference (Speed): 0…10 V

3 GND Analog input circuit common

4 +10V Reference voltage: +10 V DC, max. 10 mA

5AI2 Motor torque reference (Torque): 4…20 mA

4)

6 GND Analog input circuit common

7AO Motor speed value: 0…20 mA

8 GND Analog output circuit common

9 +24V Auxiliary voltage output: +24 V DC, max. 200 mA

10 GND Auxiliary voltage output common

11 DCOM Digital input common

12 DI1 Stop (0) / Start (1) (Speed)

13 DI2 Forward (0) / Reverse (1)

1)

14 DI3 Speed (0) / Torque (1) control selection

15 DI4 Constant speed 1: parameter 1202

16 DI5 Acceleration and deceleration selection

2)

X1B

17 ROCOM Relay output 1

No fault [Fault (-1)]

18 RONC

19 RONO

20 DOSRC Digital output, max. 100 mA

No fault [Fault (-1)]

21 DOOUT

22 DOGND

max. 500 ohm

1…10 kohm

3)

1)

Speed control: Changes rotation direction.

Torque control: Changes torque direction.

2)

0 = ramp times according to parameters

2202 and 2203.

1 = ramp times according to parameters

2205 and 2206.

3)

360 degree grounding under a clamp.

4)

The signal source is powered externally. See

the manufacturer’s instructions. To use

sensors supplied by the drive aux. voltage

output, see page 53.

Tightening torque = 0.4 N·m / 3.5 lbf·in.

Safe torque off connections (X1C:STO; not

shown in the diagram) are jumpered by default.

Loading...

Loading...